Method for synthesizing water-absorbing resin composite material by using corn bract in aqueous phase medium in one step

A technology of corn husks and water-absorbing resins, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of insufficient utilization of high-value corn husks, reduce drying energy consumption, reduce energy consumption and Cost, the effect of reducing the cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Prepare aqueous solutions of the four chemicals A, B, C, and D required for polymerization: Component A: 50wt% acrylic acid aqueous solution; B component: 15wt% sodium hydroxide aqueous solution; C component: 2wt % NN'-methylenebisacrylamide aqueous solution; D component: 2wt% ammonium persulfate aqueous solution.

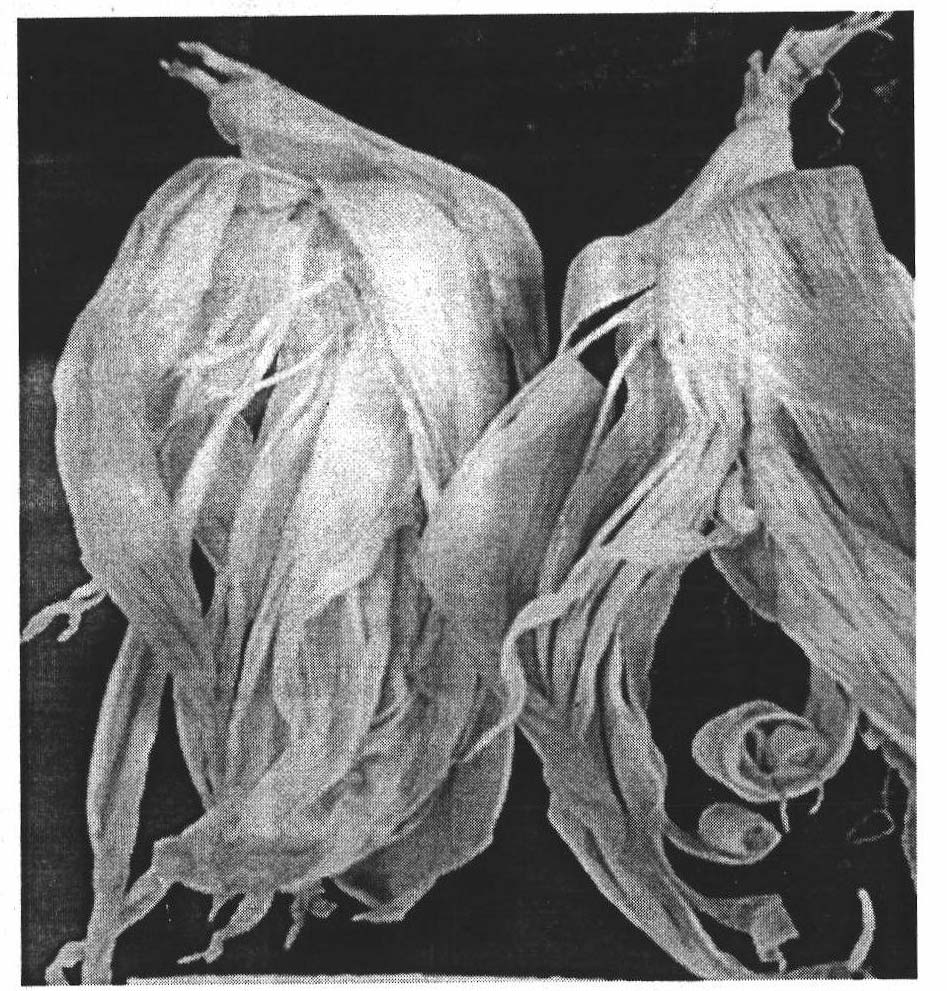

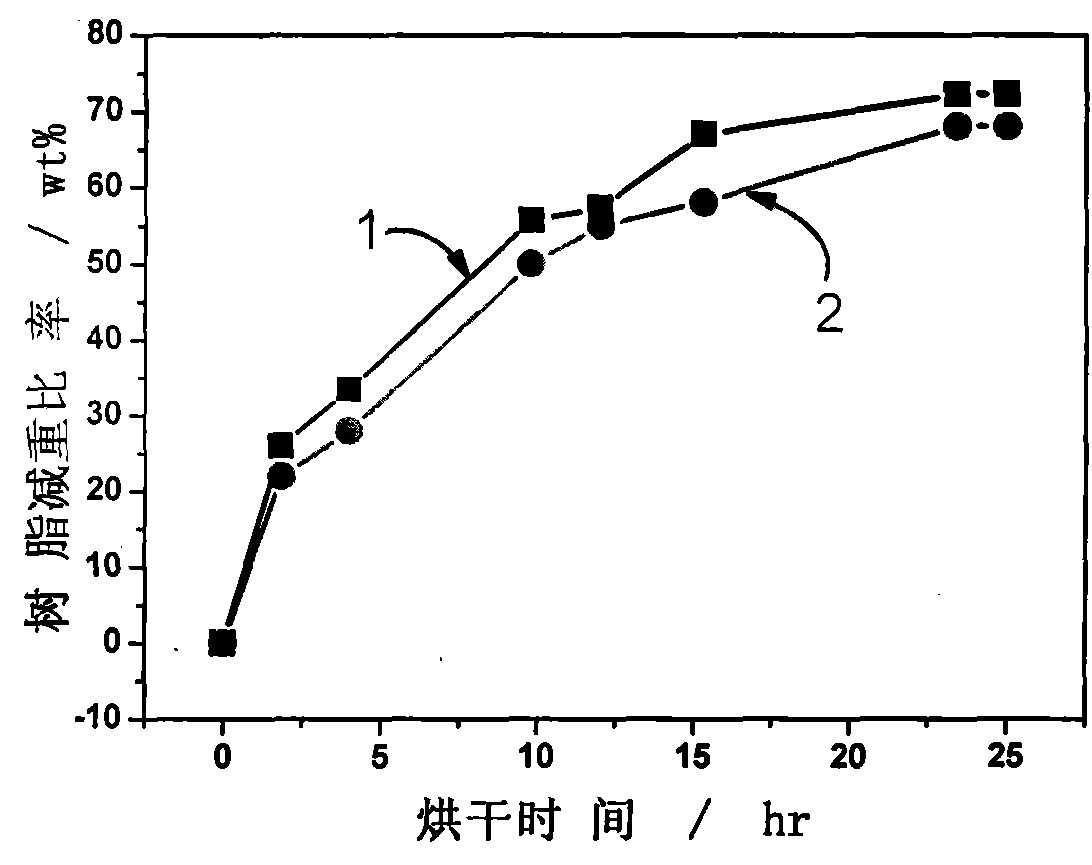

[0037] Step 2: Cutting and drying of corn husks: cut corn husks into rectangular pieces with a width of no more than 1 cm and a length of no more than 10 cm; dry in a hot air environment at 60°C for 24 hours;

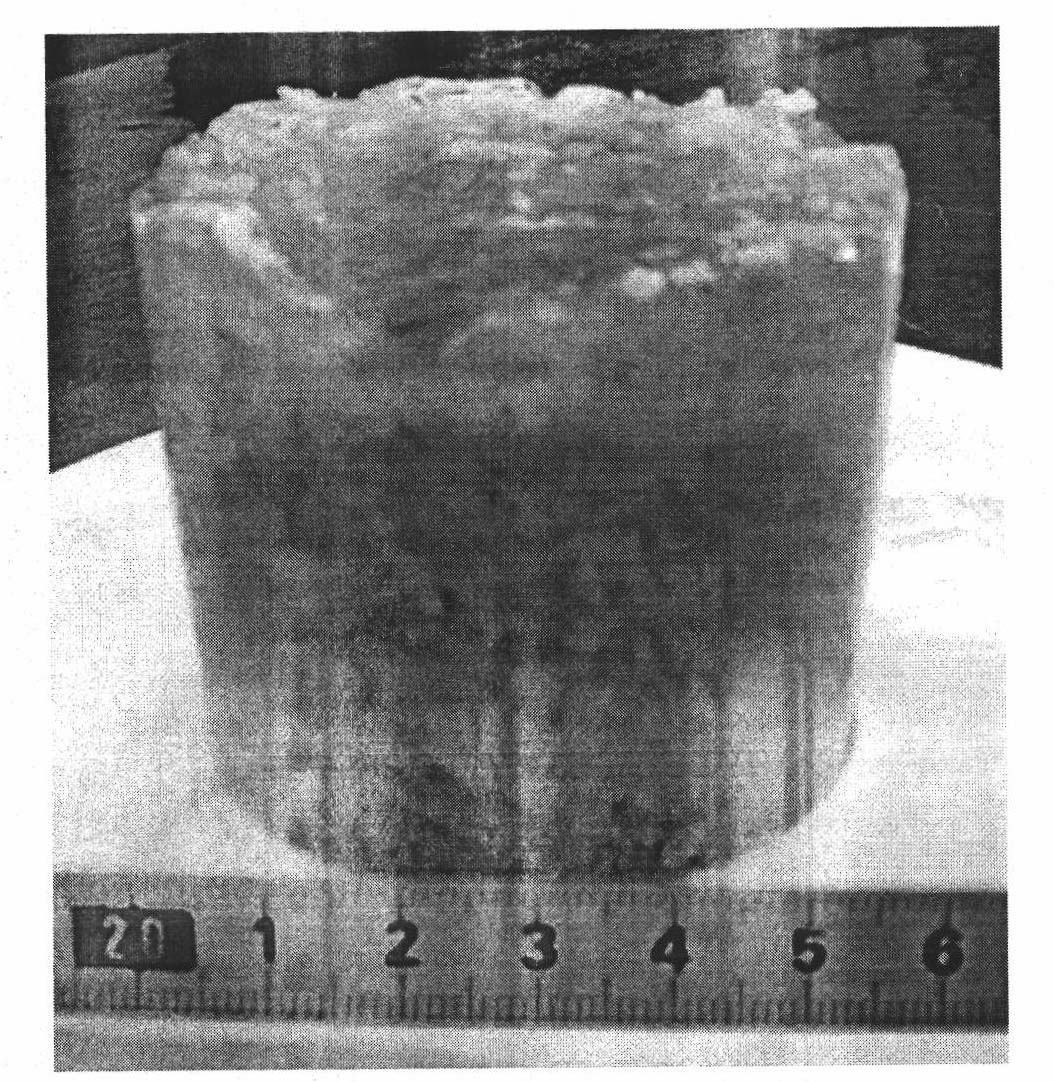

[0038]Step 3: one-step synthesis of water-absorbent resin composite material in aqueous medium: 50 grams of dried corn bract rectangular slices are soaked in 600 grams of component A for 24 hours, and then neutralized by adding 950 grams of component B. Acid-base neutralization heat is released, after the reaction system is cooled to room temperature, add 140 grams of component C, and then add 120 grams of component D, stir for 5 seconds at a ...

Embodiment 2

[0042] The difference with embodiment 1 is: in the 3rd step,

[0043] (1) Put 50 grams of corn husk rectangular slices into 650 grams of component A and soak for 24 hours.

[0044] (2) The addition amount of component B is 960 grams.

[0045] (3) The addition amount of component C is 150 grams.

[0046] (4) The addition amount of D component is 125 grams.

[0047] (5) The polymerization time is 2 hours by heating in a constant temperature water bath at 60 degrees Celsius.

[0048] The water absorption capacity of the water-absorbent resin composite material was measured by the Ni mesh method of Example 1, and the water absorption capacity of the deionized water was 295 times. The water absorption rate of "normal saline solution" is 75 times. The water absorption rate of absorbing city tap water is 261 times.

Embodiment 3

[0050] The difference with embodiment 1 is: in the 3rd step,

[0051] (1), 50 grams of rectangular corn husks were put into 700 grams of component A, ie soaked in 50 wt% acrylic acid aqueous solution for 24 hours.

[0052] (2), the addition amount of component B is 960 grams.

[0053] (3), the addition amount of C component is 160 grams.

[0054] (4), the add-on of D component is 130 grams.

[0055] (5), the polymerization time is 1.5 hours with 60 degrees centigrade constant temperature water bath heating.

[0056] The water absorption capacity of the water-absorbent resin composite material was measured by the Ni mesh method of Example 1, and the water absorption capacity of the deionized water was 280 times. The water absorption rate of "normal saline solution" is 72 times. The water absorption rate of absorbing city tap water is 258 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com