Online laser quenching process for strengthening steel rail surface

A technology of laser quenching and surface treatment, applied in the direction of track, track laying, track maintenance, etc., can solve the problems of large laser volume, reduced rail toughness, unsuitable for steel rail, etc., and achieves the effect of small size, small deformation of workpiece, and convenient adjustment and control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

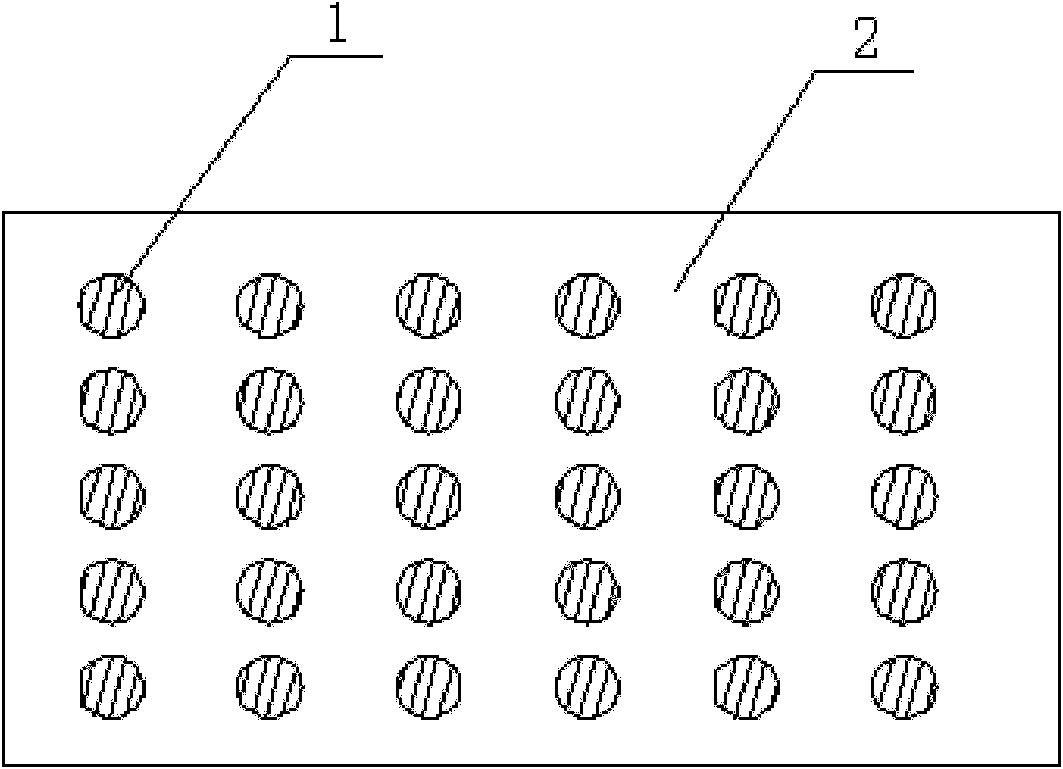

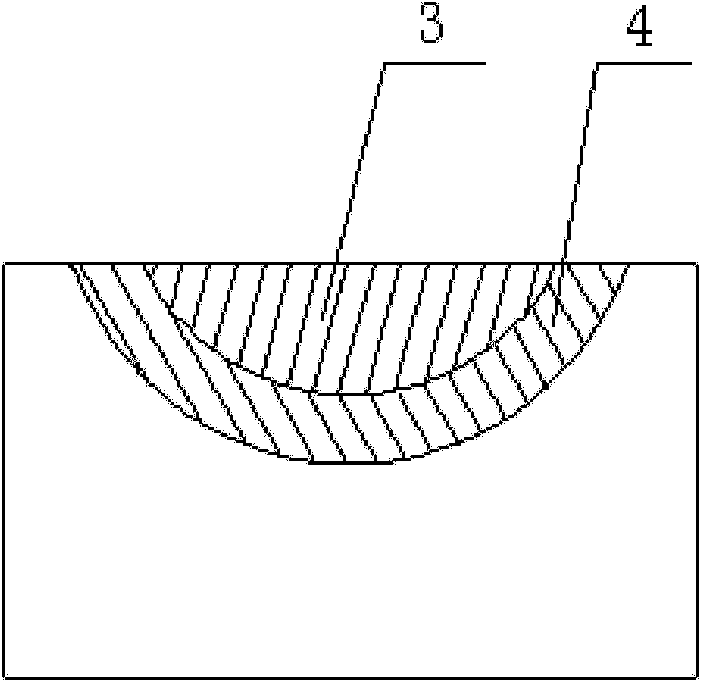

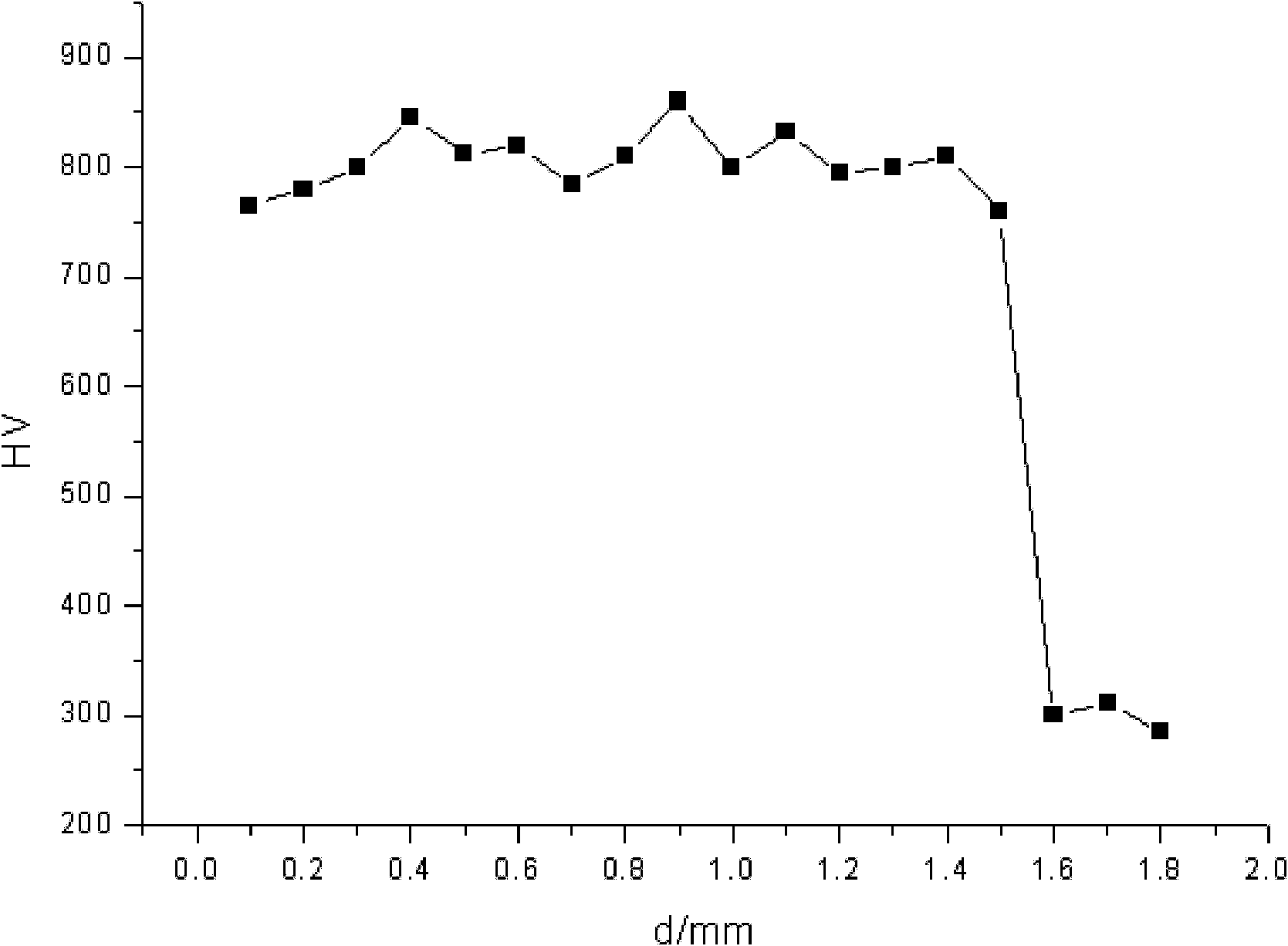

Embodiment 1

[0027] First, use sandpaper to polish the surface of the rail to remove oxides and dirt such as rust on the surface of the rail, and then use alcohol to further remove the oil on the surface of the rail to facilitate the absorption of the light-absorbing coating. Then the mass fraction is 70% of graphite particles, 15% of ZnO particles and 15% of TiO 2 The particles are mixed with water to obtain a light-absorbing paint. The stone grinding particles, ZnO particles and TiO 2 Particles are submicron particles with a particle size of less than 1 micron. Then spray a layer of light-absorbing paint on the surface of the cleaned U71Mn rail with a spray gun to form a spray coating with a thickness of 0.01 mm. Finally, the semiconductor laser mounted on the trolley and capable of emitting pulsed laser is scanned along the length direction of the rail at a speed of 2 mm / s to form a grid-shaped point-like quenching zone on the surface of the rail. The pulsed laser is realized by a fa...

Embodiment 2

[0030] After polishing the surface of the rail with sandpaper to remove rust and other oxides and dirt on the surface of the rail, use alcohol to further remove the oil on the surface of the rail to facilitate the absorption of the light-absorbing coating. Graphite particles with a mass fraction of 80%, ZnO particles with a mass fraction of 10% and TiO particles with a mass fraction of 10% 2 The particles are mixed with water to obtain a light-absorbing paint. The stone grinding particles, ZnO particles and TiO 2Particles are submicron particles with a particle size of less than 1 micron. Then apply a layer of light-absorbing paint on the surface of the cleaned U75V rail with a brush to form a spray coating with a thickness of 0.01mm. Finally, the semiconductor laser mounted on the trolley and capable of emitting pulsed laser is scanned at a speed of 6mm / s along the length of the rail to form a grid-shaped point-like quenching zone on the surface of the rail. The pulsed las...

Embodiment 3

[0033] After polishing the surface of the rail with sandpaper to remove oxides and dirt such as rust on the surface of the rail, alcohol is used to further remove the oil on the surface of the rail to facilitate the absorption of the light-absorbing coating. Then the mass fraction is 75% of graphite particles, 12% of ZnO particles and 13% of TiO 2 The particles are mixed with water to obtain a light-absorbing paint. The stone grinding particles, ZnO particles and TiO 2 Particles are submicron particles with a particle size of less than 1 micron. Then spray a layer of light-absorbing paint on the surface of the cleaned U71Mn rail with a spray gun to form a spray coating with a thickness of 0.1mm. Finally, the semiconductor laser mounted on the trolley and capable of emitting pulsed laser is scanned at a speed of 10 mm / s along the length of the rail to form a grid-shaped point-like quenching zone on the surface of the rail. The pulsed laser is realized by a fan blade type opt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com