Anticorrosive TPO modified asphalt composite waterproof coiled material and preparation method thereof

A technology of modified asphalt and waterproof membrane, applied in asphalt layered products, chemical instruments and methods, and roofs using flexible materials, etc., can solve problems such as material corrosion, facility corrosion, air pollution, etc., and achieve a simple and scientific preparation method , excellent corrosion resistance and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: (100 kilograms per weight part)

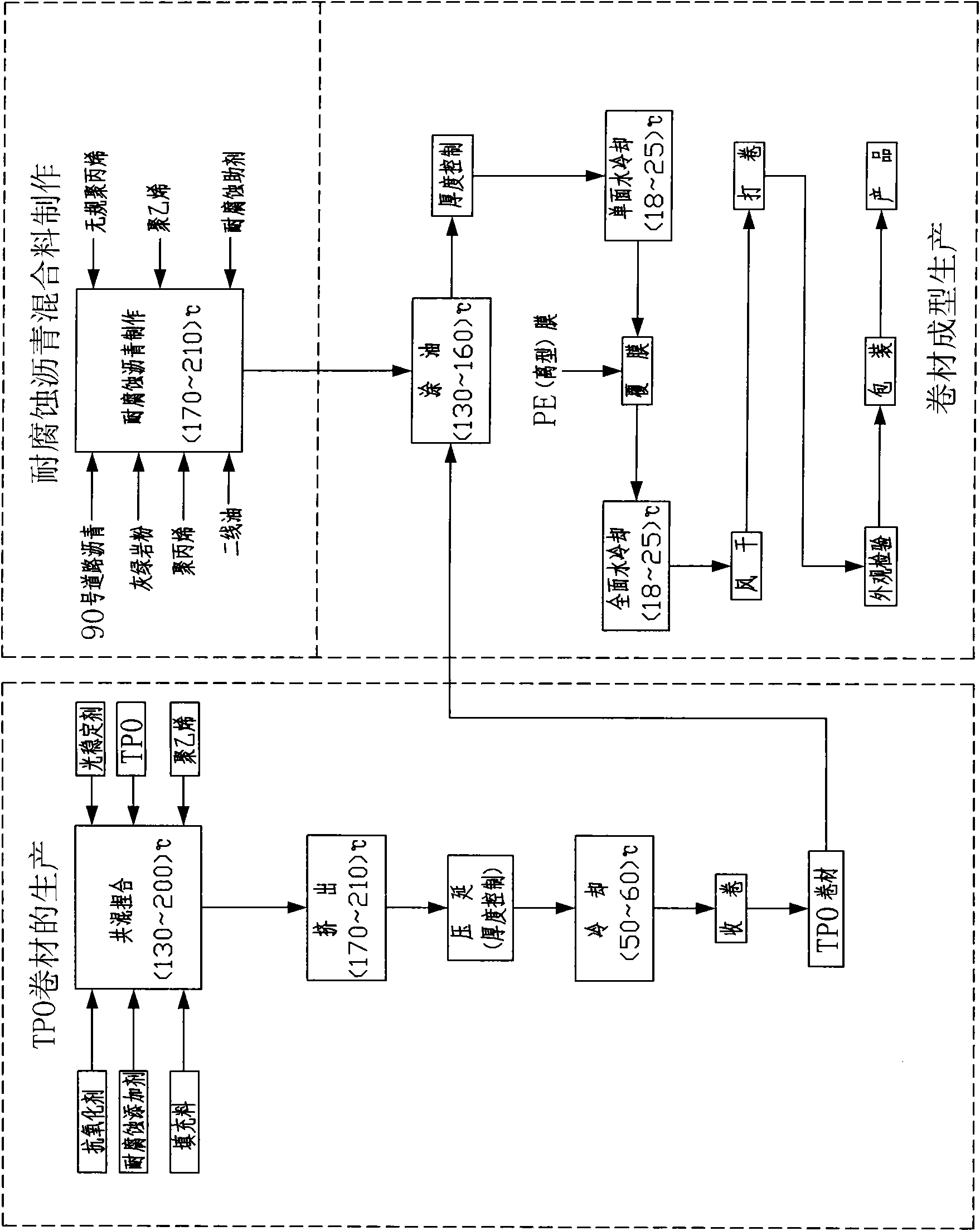

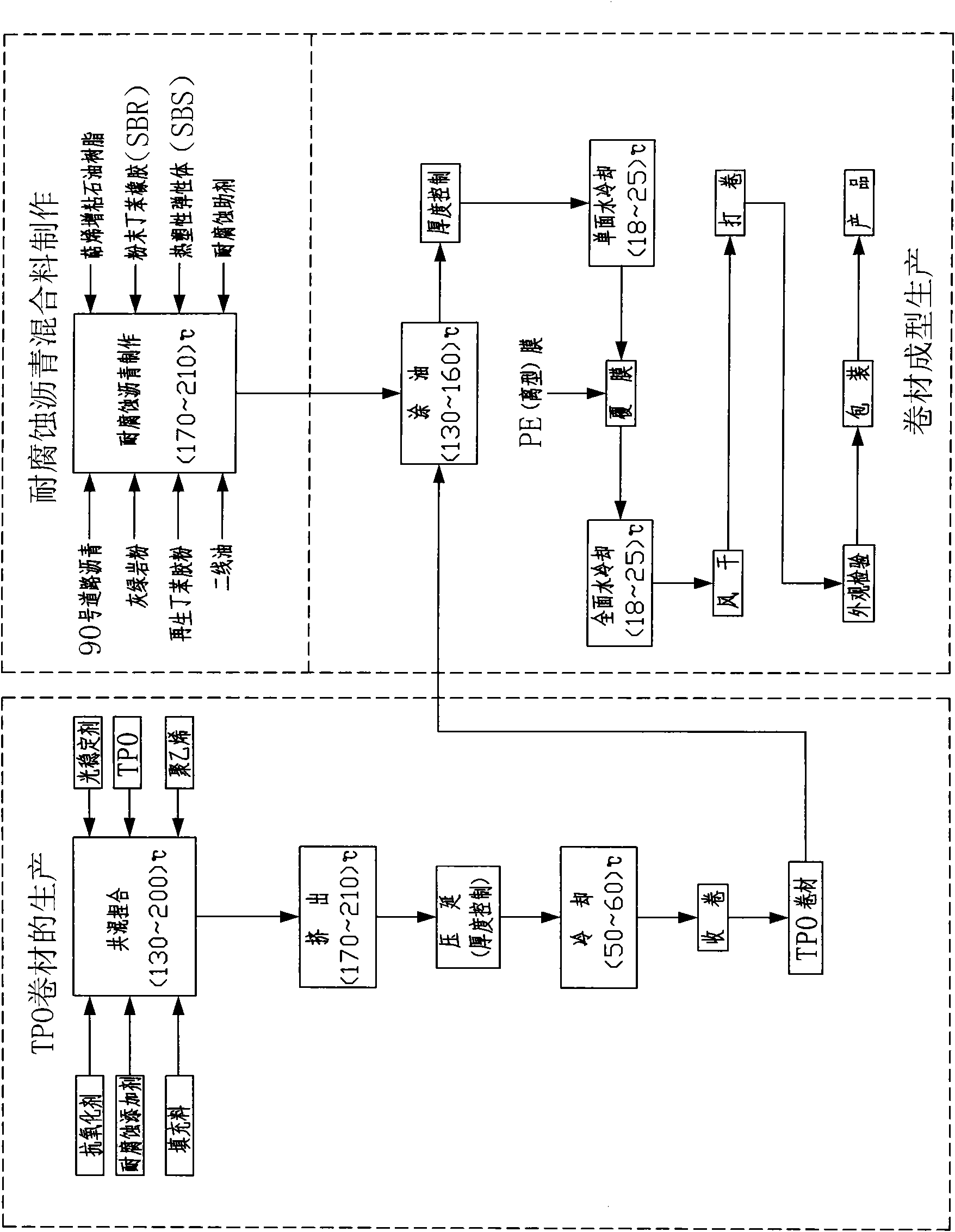

[0035] Such as figure 2 , image 3 As shown, the preparation of corrosion-resistant TPO modified asphalt composite waterproof membrane is divided into the following three steps:

[0036] 1. Preparation of thermoplastic polyolefin (TPO) material layer

[0037] The TPO material layer is prepared by a conventional method. According to the technical requirements, TPO, polyethylene, corrosion-resistant additives, antioxidants, light stabilizers, fillers, etc. are blended and kneaded at a temperature of 130 ° C to 200 ° C, and passed through a single-screw extruder. Extrude and calender at 180°C, and control the thickness to make a TPO material layer with a width of 1.0m and a thickness of 0.5mm, cool it with water at 50°C to 60°C, and roll it up for later use.

[0038] 2. Preparation of corrosion-resistant modified asphalt mixture for self-adhesive construction

[0039] Add 4,770 kg of No. 90 road asphalt, 1,480 kg of seco...

Embodiment 2

[0042] Embodiment 2: (100 kilograms per weight part)

[0043] Such as figure 2 , image 3 As shown, the preparation of corrosion-resistant TPO modified asphalt composite membrane is divided into the following three steps:

[0044] 1. Preparation of thermoplastic polyolefin (TPO) material layer

[0045] The TPO material layer is prepared by conventional methods. According to technical requirements, raw materials such as TPO, polyethylene, antioxidants, light stabilizers, corrosion-resistant additives, and fillers are blended and kneaded at a temperature of 130°C to 200°C, and passed through a single-screw extruder. , extruded and calendered at 185°C, with thickness control, to make a TPO material layer with a width of 1.0 meters and a thickness of 1.0mm, cooled by 50-60°C water, trimmed and rolled for later use.

[0046] 2. Preparation of corrosion-resistant modified asphalt mixture for self-adhesive construction at room temperature

[0047] Add 4550kg of No. 90 road aspha...

Embodiment 3

[0050] Embodiment 3 (100 kilograms per weight part):

[0051] Such as figure 2 , image 3 As shown, the preparation method of corrosion-resistant TPO modified asphalt composite waterproof membrane is divided into the following three steps:

[0052] 1. Preparation of thermoplastic polyolefin (TPO) material layer

[0053] The TPO material layer is prepared by conventional methods. According to technical requirements, raw materials such as TPO, polyethylene, antioxidants, light stabilizers, corrosion-resistant additives, and fillers are blended and kneaded at a temperature of 130°C to 200°C, and passed through a single-screw extruder. , extruded and calendered at 190°C, with thickness control, to make a TPO material layer with a width of 2.0 meters and a thickness of 1.2mm, cooled by water at 50°C to 60°C, trimmed and rolled for later use.

[0054] 2. Preparation of corrosion-resistant modified asphalt mixture for hot-melt construction

[0055] Add 5,500 kg of No. 90 road as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com