Ultrasonic ground experimental wind tunnel used for knocking combustion research

A ground experiment, detonation combustion technology, applied in the direction of aerodynamic test, machine/structural component test, measuring device, etc., can solve difficult detonation and development dynamic process research, quality reduction of premixed flow field, effective experiment Time is short and other issues, to achieve the effect of lowering temperature, reducing difficulty, reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

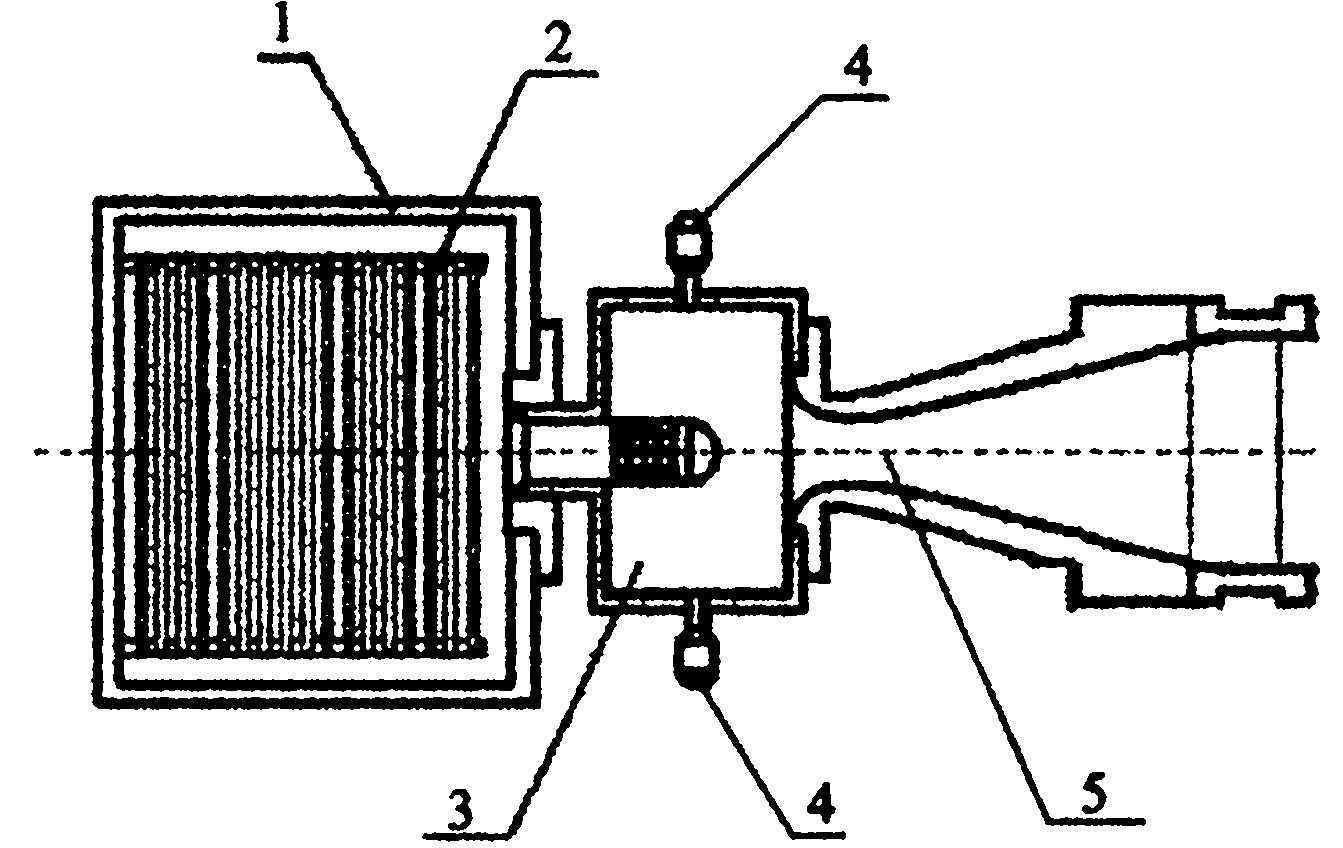

[0053] mistake! Reference source not found. It is a schematic diagram of the Φ0.1m, 2.0m long continuous experimental wind tunnel developed by the Russian Institute of Theoretical and Applied Mechanics. The experimental wind tunnel uses high-pressure air as the air source, and the cold air enters the pre-combustion chamber 1 through the pressure regulating system, where the high-pressure air flows through the electric heating air heater 2 to increase the total temperature; driven by the pressure, the hot air enters the mixing chamber 3 , and mixed here with the hydrogen injected by the fuel nozzle 4; finally, through the acceleration of the nozzle 5, a continuous supersonic premixed flow meeting the experimental conditions is obtained.

[0054] Figure 4 It is a supersonic premixed gas ground test wind tunnel designed by the present invention, including a supersonic premixed heater, an experimental section and a vacuum chamber. The supersonic premix heater includes an injec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com