Coating material for furnace wall of coke furnace carbonization chamber and using method thereof

A carbonization chamber and furnace wall technology, applied in the field of refractory materials, can solve problems such as aggravating furnace wall damage, and achieve the effects of excellent thermal shock resistance, high hardness and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

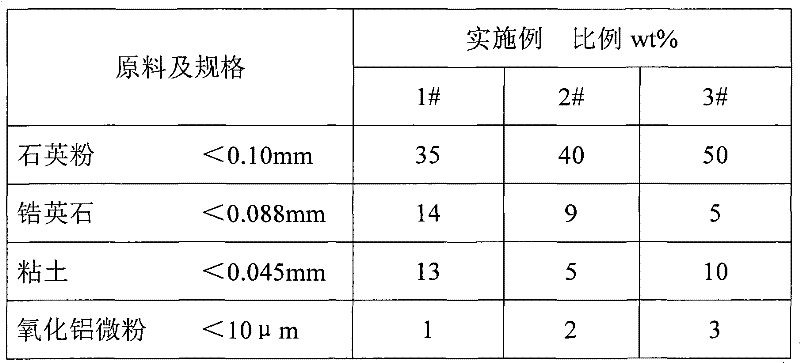

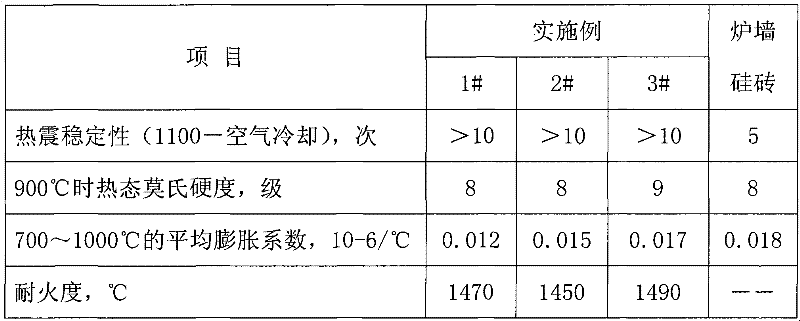

[0047] The basic composition of the coating materials of Example 1, Example 2 and Example 3 is shown in Table 1. Mainly use SiO 2 -Al 2 o 3 -ZrO 2 It is a variety of flux materials for refractory raw materials and ceramics.

[0048] The composition of table 1 embodiment

[0049]

[0050] Lepidolite <0.15mm

18

24

10

Feldspar<0.088mm

15

13

10

2

4

6

Borax <0.15mm

Or boric acid <0.15mm

--

1

--

2

4

--

1

--

1

--

--

2

[0051] After proportioning according to Table 1, all raw materials are uniformly mixed and ground in a ball mill, and the coating fineness ≤ 0.074mm is more than 90 wt%, which is the finished coating material. During spraying construction, the amount of water added to the coating material is 30-50 wt%, stirred into a uniform slurry, and sprayed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com