Preparation method and use method of polishing solution for silicon carbide

A polishing liquid, silicon carbide technology, applied in polishing compositions containing abrasives, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of long processing time, scratches, unsuitable for industrial production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

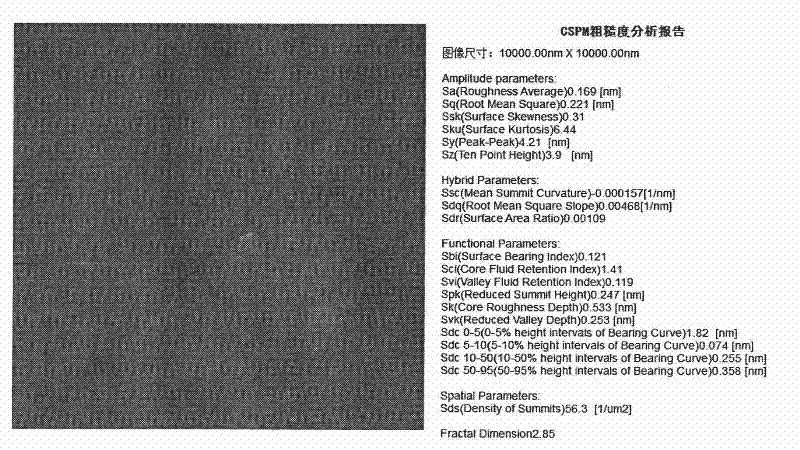

Image

Examples

Embodiment 1

[0018] Step 1: Configure Polishing Fluid

[0019] (1) Mix reagent pure (or above) potassium hydroxide and potassium pyrophosphate in deionized water according to the mass ratio of the three as 5:1:200, and stir evenly to obtain a pH regulator;

[0020] (2) Mix hydrogen peroxide and deionized water at a ratio of 4:1 by volume, and stir evenly to obtain an auxiliary oxidizing agent. The stirring speed does not exceed 100 rpm.

[0021] (3) Mix the auxiliary oxidizing agent and the silicon dioxide polishing liquid according to the ratio of volume percentage of 1:2 and stir to obtain the intermediate evenly, and the stirring speed does not exceed 100 rpm.

[0022] (4) Mix the pH regulator into the intermediate, and adjust the pH to 9-10 (9.3) and the stirring speed does not exceed 100rpm

[0023] Step Two: Use

[0024] Adjust the temperature of the polishing disc to be controlled at a constant temperature of 10 degrees Celsius, and use a peristaltic pump to flow and supply the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com