Composite pressure vessel and application thereof in extinguisher

A technology for pressure vessels and composite materials, applied in the field of pressure vessels, can solve the problems of reduced sealing performance, cracking at the lap joint, etc., and achieve the effects of good sealing performance, durable bonding effect and better bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

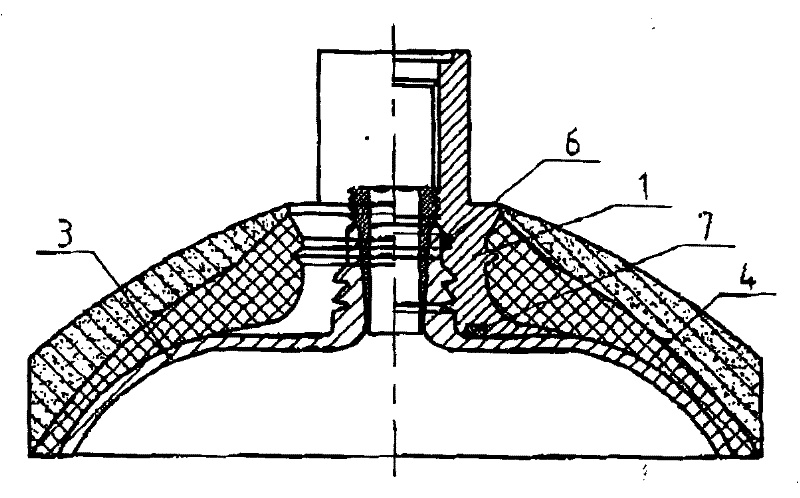

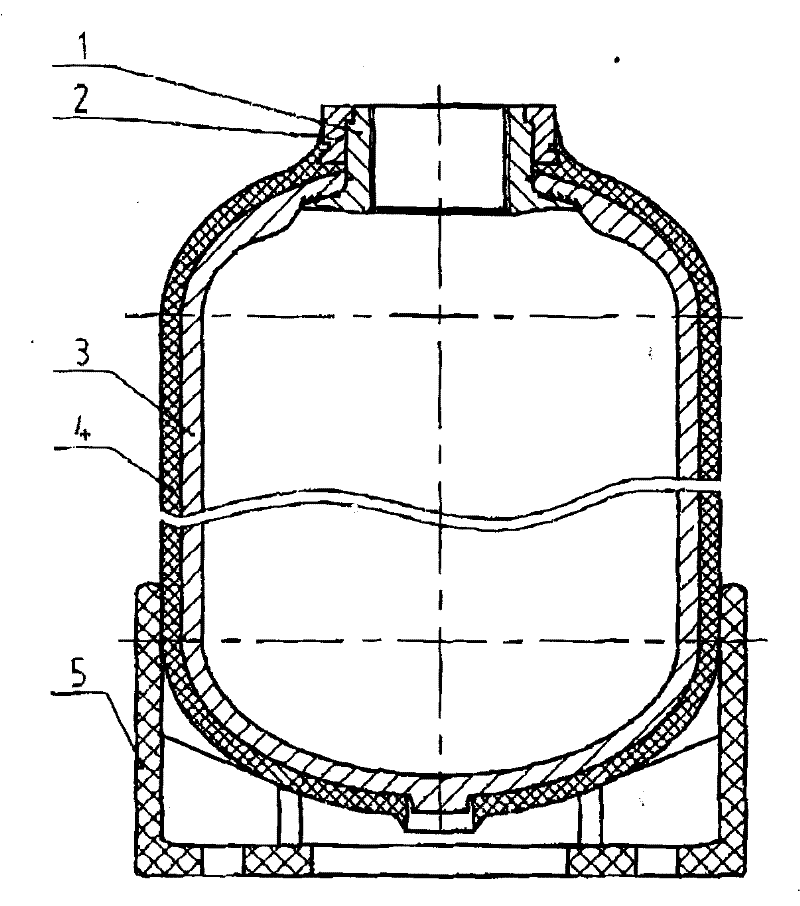

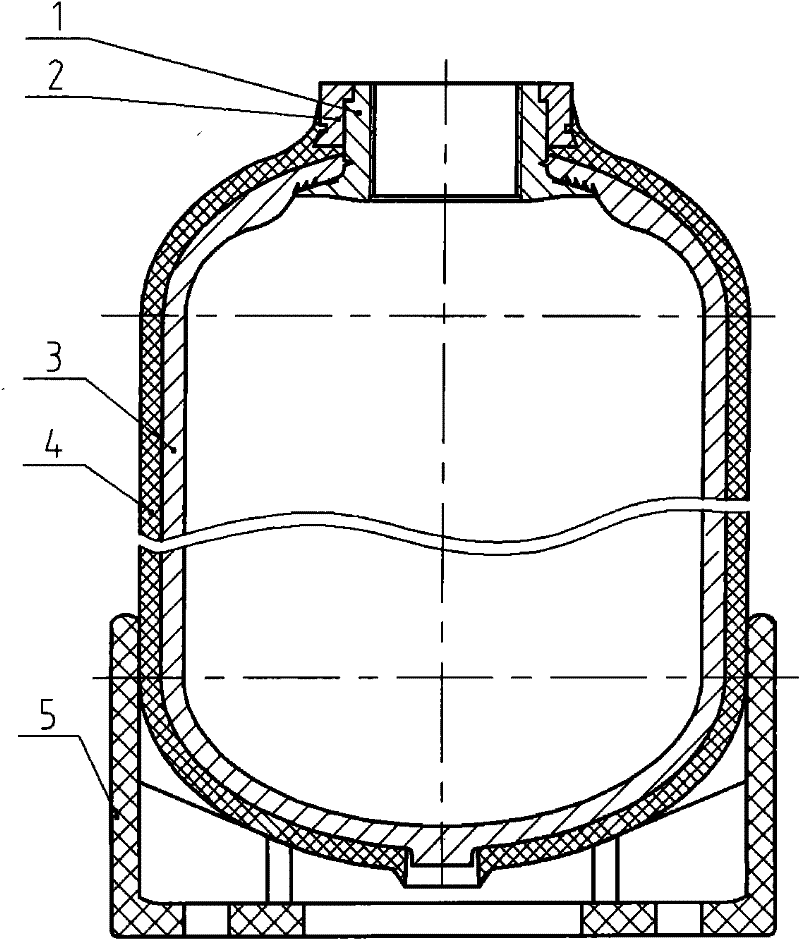

[0029] Such as figure 2 As shown, the pressure vessel of the present invention includes a base 5 for fixing the bottom, an inner tank 3, an interface 1 at the neck of the top of the inner tank 3, and a glass fiber winding layer wrapped outside the inner tank 3 and protecting the inner tank 3 4. The reinforcement ring 2 set outside the interface 1, the connection method between the liner 3 and the glass fiber winding layer 4 is bonding, and the bonding material is a mixed glue composed of epoxy resin and phenolic resin, of which epoxy resin and phenolic resin The ratio of the resin is 2.5:1, the material of the liner is polyethylene, and the material of the interface is reinforced polypropylene. The liner and the interface are connected as a whole by thermal fusion. Reinforcement ring 2 is made of aluminum, and is connected with interface 1 through transition fit or interference fit and coated with epoxy resin and phenolic resin. The strength of the reinforcement ring is suff...

no. 2 example

[0031] The only difference from the first embodiment is that the material of the liner is polypropylene, the material of the interface is reinforced polyethylene, and the ratio of epoxy resin to phenolic resin is 3.5:1.

no. 3 example

[0033] The only difference from the first embodiment is that the material of the liner is ABS, the material of the interface is reinforced ABS, and the ratio of epoxy resin and phenolic resin is 3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com