Insulation online monitoring method for high-voltage capacitive equipment

A capacitive equipment and high-voltage technology, which is applied in the field of online monitoring of the insulation performance of high-voltage capacitive equipment in substations, can solve the problems of sensors such as poor resistance to environmental temperature, humidity changes and electromagnetic interference, easy signal distortion, and potential safety hazards of electrical cables. Achieve the effect of improving anti-interference performance, solving anti-electromagnetic interference, and suppressing various interferences

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

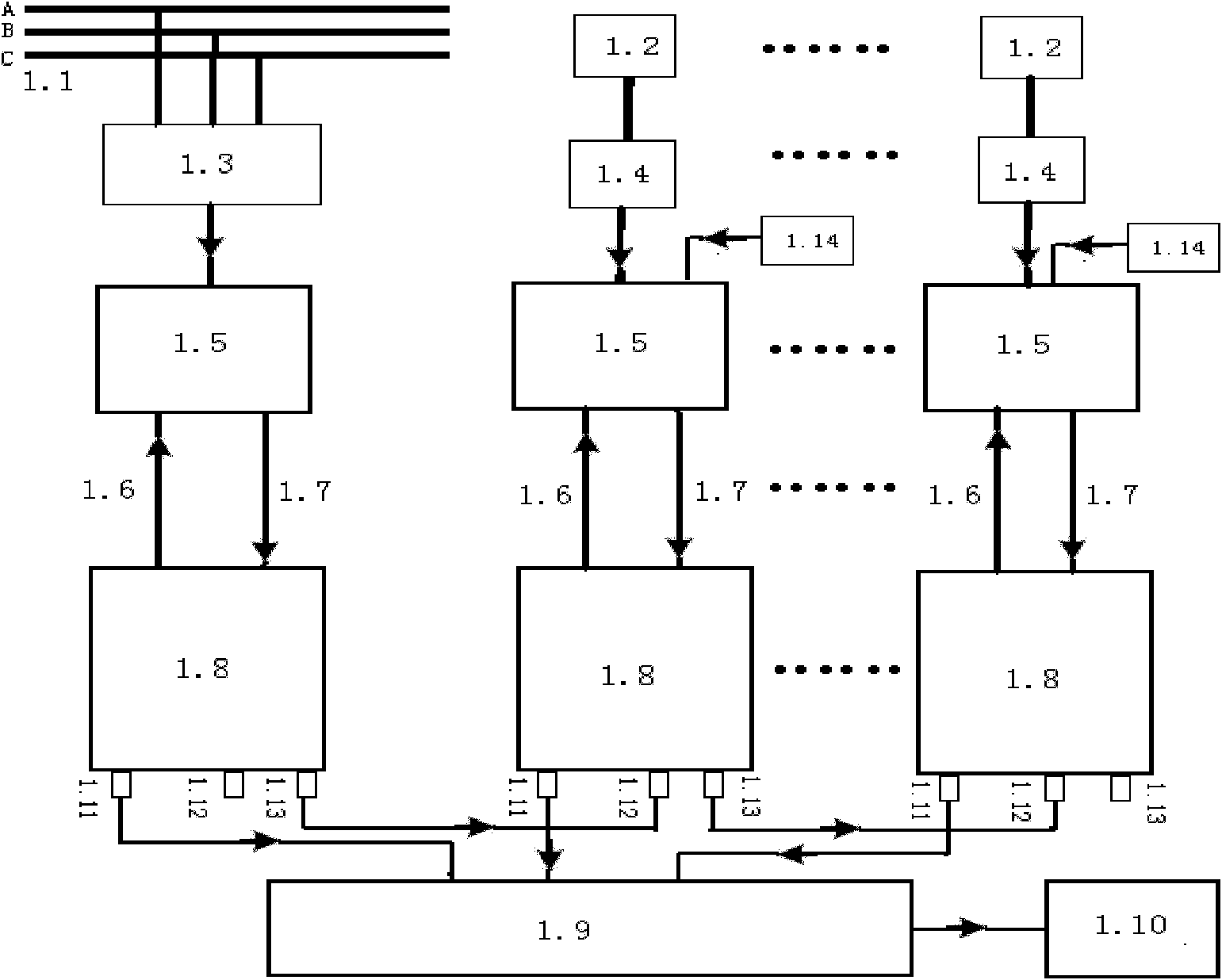

[0034] see figure 1 In the present invention, the voltage signal is obtained from the high-voltage busbar 1.1 of the substation through the secondary terminal of the substation voltage transformer and the secondary voltage dividing coil 1.3. The current signal is obtained by the zero-flux micro-current sensor 1.4 on the ground wire at the end screen of the substation capacitive equipment 1.2. The ambient temperature and humidity parameters are obtained by the temperature and humidity sensor 1.14.

[0035]The voltage, current and temperature and humidity signals of the sensor are collected and transmitted synchronously by the optical power supply data link OPDL. Each set of optical power supply data link OPDL includes a remote module 1.5 and a local module 1.8, and they are connected by two optical fibers, respectively energy optical fiber 1.6 and data optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com