Polymer-based magnetodielectric material and process thereof for manufacturing electronic device

A technology of magnetic dielectrics and polymers, which is used in electrical components, waveguide-type devices, inorganic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

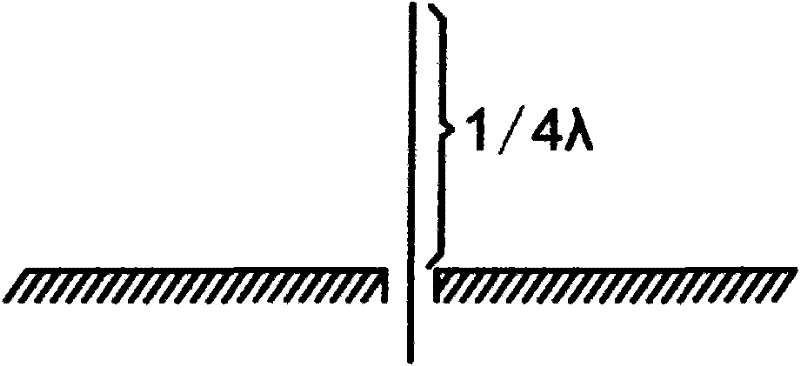

[0055] The invention achieves the purpose of the invention from the aspects of antenna space structure design, material selection, manufacturing process, device performance guarantee, etc. The specific implementation method is:

[0056] Structural design:

[0057] Use polymer substrate surface winding or selective metallization technology, and then cover the resin process; the specific structure sequence is:

[0058] Step 1: Injection-molding regular-shaped chip or rod-shaped antenna inner tubes with polymer magnetic dielectric materials that have been kneaded, and metal terminals can be embedded in the injection molding process;

[0059] Step 2: Wind metal wires or print conductive ink, paint, or laser-induced metallization wiring on the inner tube of the antenna; the metallized wires are in good contact with the embedded metal terminals.

[0060] Step 3: Encapsulate the device with resin on the basis of the above step 2.

[0061] Material Design:

[0062] Polymer raw mate...

Embodiment 1

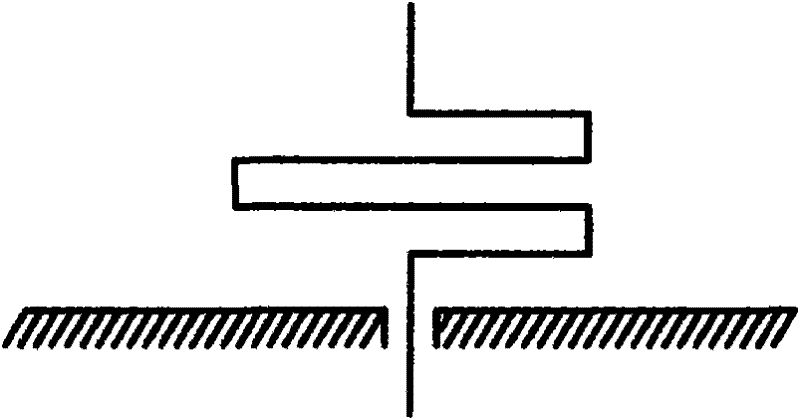

[0077] Figure 6 Shown is the structural diagram of the chip antenna of the embodiment of the present invention, the antenna inner tube (6-1) is made by using the polymer magnetic dielectric material and the injection molding process described in the present invention; the metal terminal (6-4) is embedded in the injection molding; Wind the metal wire (6-2) on the surface of the antenna inner tube, and weld one end of the metal wire (6-2) to the metal terminal (6-4); repackage the resin (6-3)

Embodiment 2

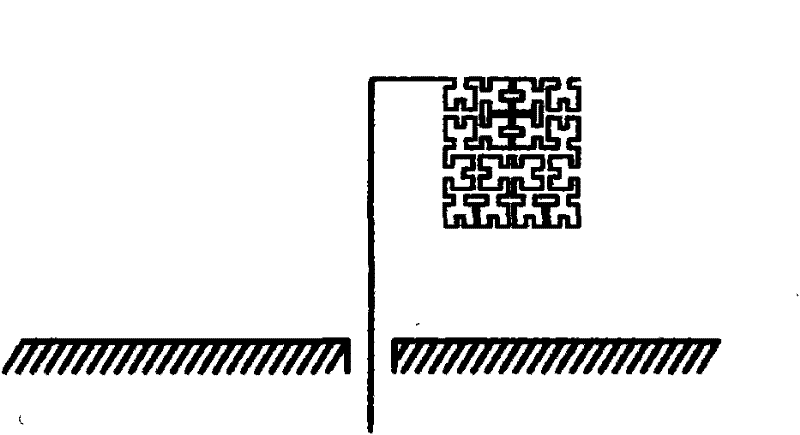

[0079] Figure 7 It is a schematic diagram of the appearance of the rod antenna of the example of the present invention,

[0080] Among them, 7-1 is the metal terminal at the bottom, and 7-2 is the metal terminal at the side;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com