Corn bean pulp type feed complex enzyme additive and application thereof

A corn-soybean meal-based compound enzyme technology, which is applied in the field of feed additives and corn-soybean meal-based feed compound enzyme additives, can solve the problems of reducing the feed-to-meat ratio, achieve the effects of reducing the feed-to-meat ratio, eliminating anti-nutritional effects, and improving digestibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to xylanase 10%, cellulase 10%, β-mannanase 8%, α-galactosidase 15%, acid protease 10%, medium temperature amylase 10%, glucoamylase 10%, carrier 27 The ratio of % is uniformly combined to obtain a special compound enzyme feed additive of corn soybean meal type, and its main component analysis guarantee value is: xylanase 6000U / g; cellulase 700U / g; β-mannanase 2500U / g; α-galactosidase 300U / g; acid protease 10000U / g; medium temperature amylase 600U / g; glucoamylase 20000U / g.

[0021] Add the additive at 0.2‰ of the weight of the full-price compound feed.

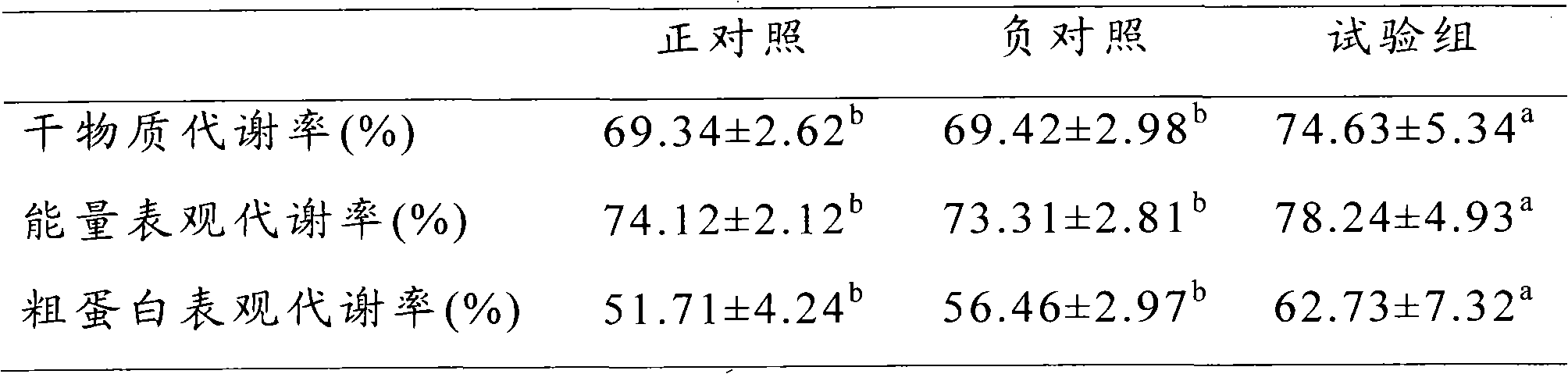

[0022] The experiment adopts a single factor completely random design, selects 750 AA broilers of similar origin, age and body weight, and randomly divides them into 3 treatments, each treatment has 5 repetitions, and each repetition has 50 chickens. Positive control group, negative control group and test group were respectively set up, fed with corn-soybean meal-based ration, corn-soybean meal-based ration w...

Embodiment 2

[0028] Xylanase 12%, Cellulase 15%, β-Mannanase 5%, α-Galactosidase 5%, Acid Protease 5%, Moderate Amylase 10%, Glucoamylase 5%, Carrier 43% Combining uniform proportions, a special compound enzyme feed additive of corn soybean meal type is obtained, and its main component analysis guarantee values are: xylanase 7200U / g; cellulase 1000U / g; β-mannanase 2000U / g; α -Galactosidase 100U / g; acid protease 7500U / g; medium temperature amylase 600U / g; glucoamylase 10000U / g.

[0029] Add the additive at 0.5‰ of the weight of the full-price compound feed.

[0030] The formula in this example is more suitable for pigs, and the effect is very good.

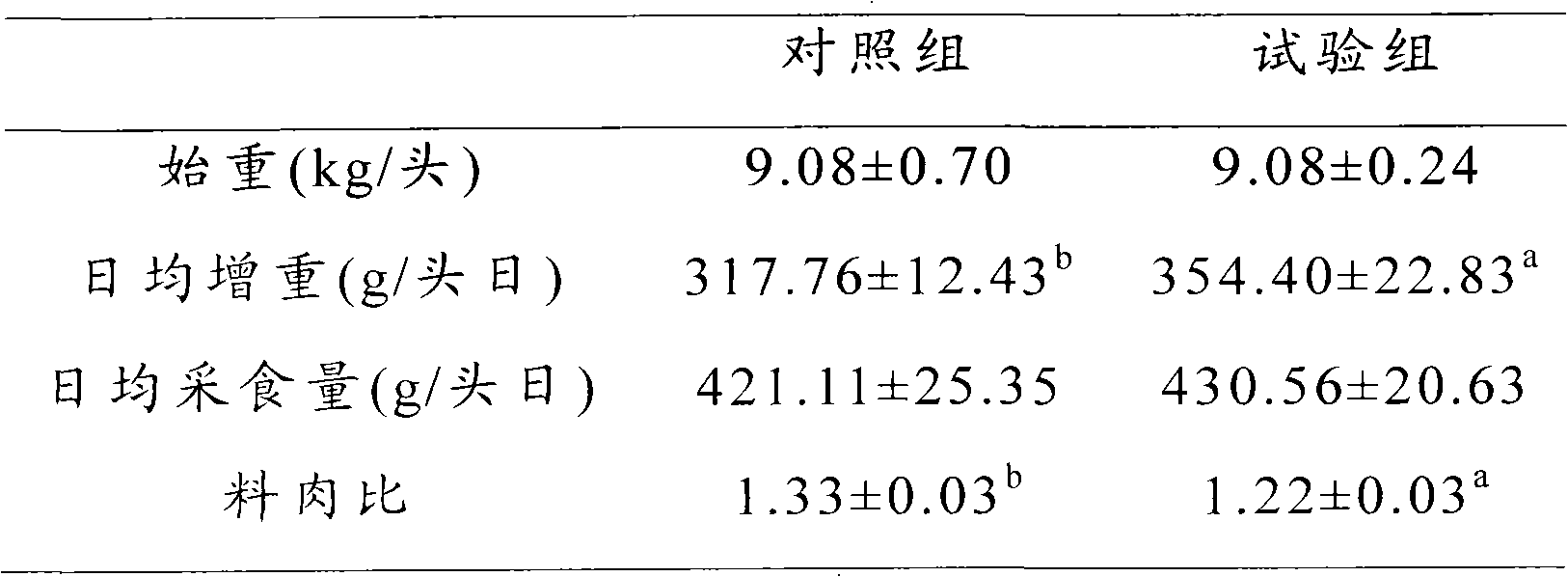

[0031] The piglet experiment was carried out with the special compound enzyme feed additive of corn and soybean meal. The present embodiment is divided into a control group and a test group, and selects 48 piglets with an average body weight of 9.08 kg and is divided into two groups, each group is divided into three repetitions (columns), a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com