Compound polyethylene glycol electrolyte pulvis and preparation method thereof

A polyethylene glycol and electrolyte technology, applied in the field of medicine, can solve the problems of waste, uncontrollable quality, and uneven loading, and achieve the effects of overcoming uneven mixing, improving quality and efficacy, and accelerating dissolution speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

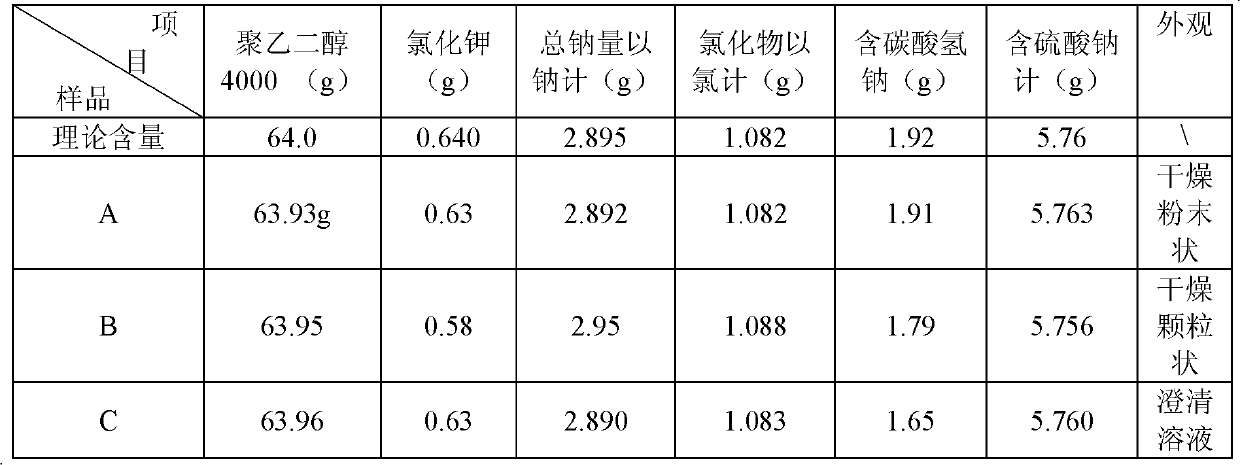

Embodiment 1

[0050] Weigh 64000g of polyethylene glycol (4000), 1280g of sodium chloride, 5760g of anhydrous sodium sulfate, 640g of potassium chloride, and 1920g of sodium bicarbonate, and set aside; put the above-mentioned standby materials in a mixer and mix for 30 minutes, then take a sample for detection Intermediate content, after passing the test, calculate the filling amount according to the intermediate content, and put it into aluminum-plastic composite film bags. Each bag contains 64g of polyethylene glycol (4000), 1.28g of sodium chloride, 5.76g of anhydrous sodium sulfate, 0.64g of potassium chloride, and 1.92g of sodium bicarbonate.

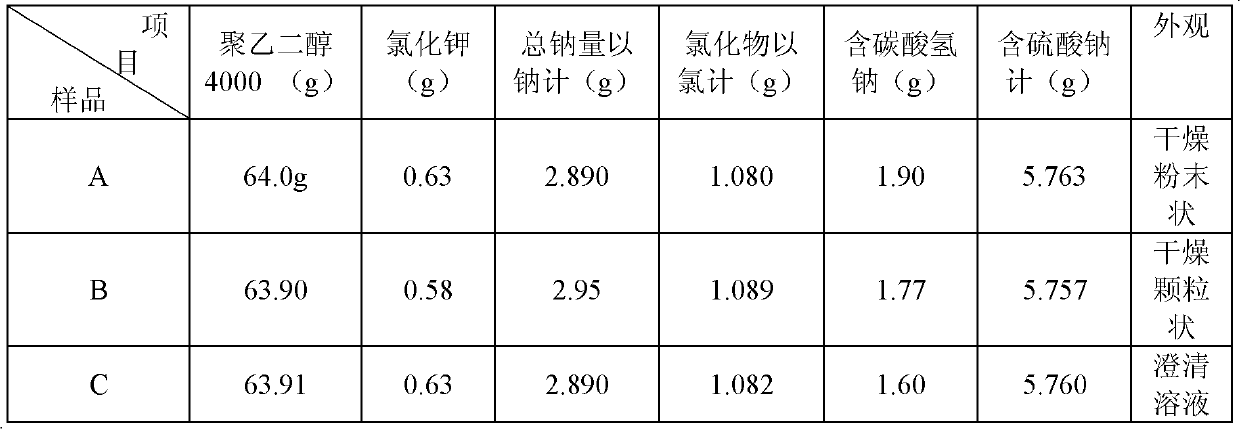

Embodiment 2

[0052] Weigh 64000g of polyethylene glycol (4000), 1280g of sodium chloride, 5760g of anhydrous sodium sulfate, 640g of potassium chloride, 1920g of sodium bicarbonate, 640g of hydroxypropyl methylcellulose, and set aside; After mixing in the machine for 40 minutes, take a sample to detect the content of the intermediate. After passing the test, calculate the filling amount according to the intermediate content, divide it into graduated infusion bottles, add stoppers, and press the caps to seal. Each bag contains 64g of polyethylene glycol (4000), 1.28g of sodium chloride, 5.76g of anhydrous sodium sulfate, 0.64g of potassium chloride, 1.92g of sodium bicarbonate, and 0.64g of hydroxypropyl methylcellulose.

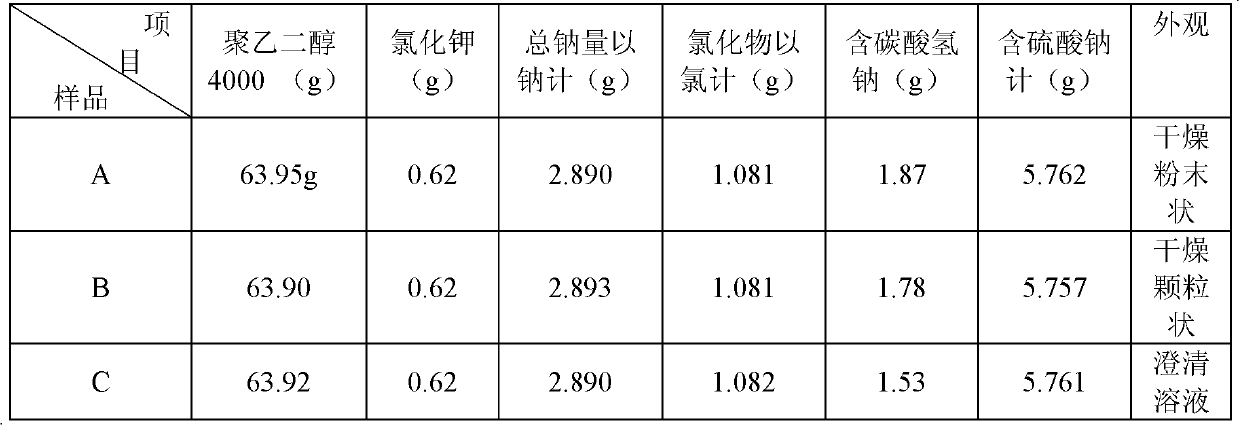

Embodiment 3

[0054] Weigh polyethylene glycol (4000) 64000g, sodium chloride 640g, anhydrous sodium sulfate 3200g, potassium chloride 448g, sodium bicarbonate 576g, hydroxypropyl methylcellulose 640g, standby; Put the above standby materials in the mixing After mixing in the machine for 40 minutes, take a sample to detect the content of the intermediate. After passing the test, calculate the filling amount according to the intermediate content, divide it into graduated infusion bottles, add stoppers, and press the caps to seal. Each bag contains 64g of polyethylene glycol (4000), 0.64g of sodium chloride, 3.2g of anhydrous sodium sulfate, 0.448g of potassium chloride, 0.576g of sodium bicarbonate, and 0.64g of hydroxypropyl methylcellulose.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com