Cobalt-based amorphous giant magneto-impedance ribbon and preparation method thereof

A technology of giant magneto-impedance and thin strips, applied in the preparation of the giant magneto-impedance thin strips, in the field of cobalt-based amorphous giant magneto-impedance thin strips, can solve problems such as difficult popularization, complex thin film preparation process, difficulty in controlling composition uniformity, etc. problems, to achieve excellent soft magnetic properties and toughness, improve production efficiency, and save processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

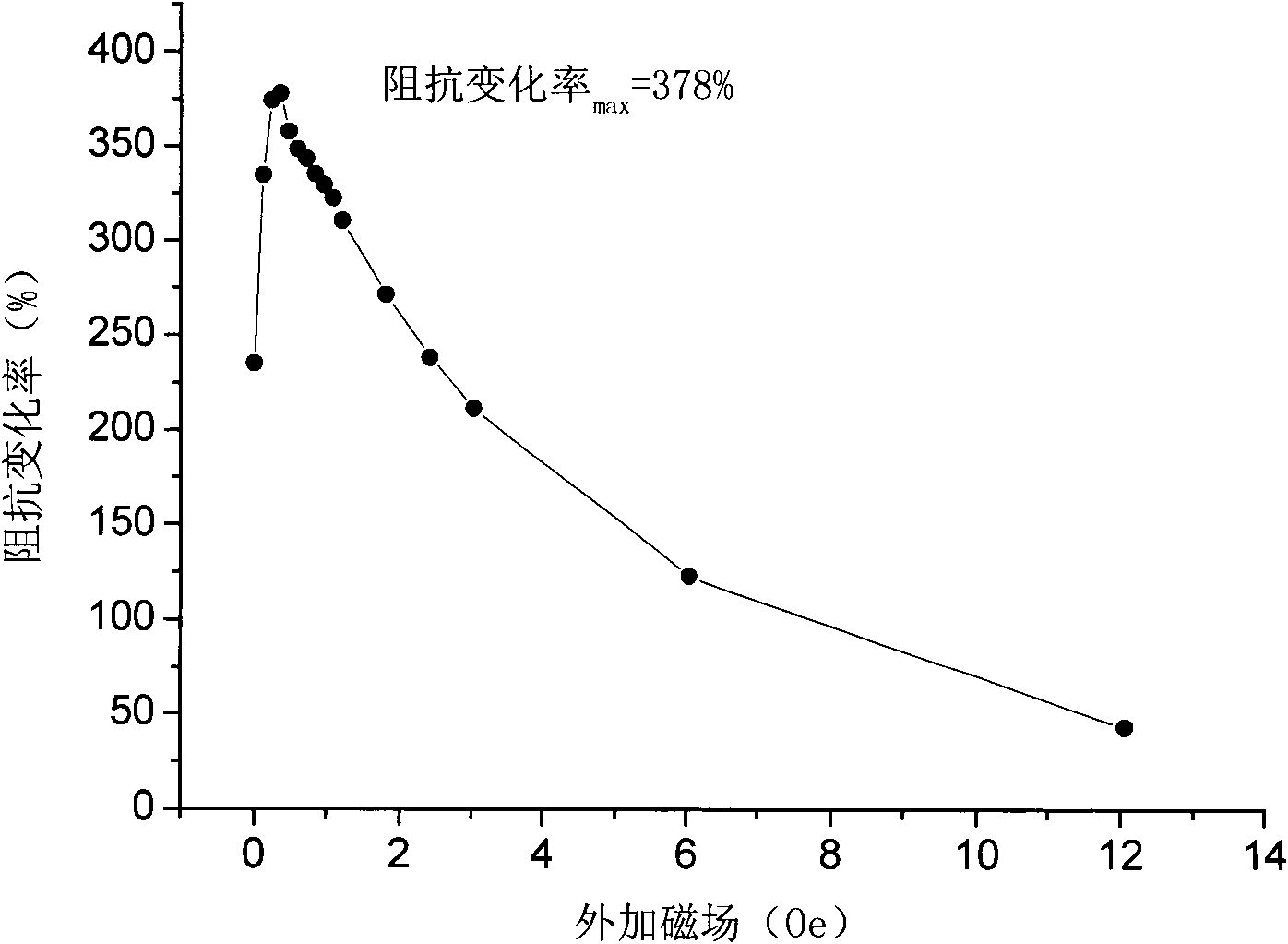

[0022] Embodiment 1, the material composition of this example is composed of Co 66 Fe 4 V 2 Si 8 B 20 , according to the composition of chemical elements, the purity of the raw materials is ≥99.9%, put the prepared raw materials into the vacuum induction melting furnace, vacuumize, when the vacuum degree reaches 0.01Pa, fill with argon gas with a purity of 99.99%, and the air pressure is controlled at 1.2 atmospheric pressure, the melting temperature is about 1300 ℃, the time is 25 minutes, and the master alloy is obtained by cooling with the furnace.

[0023] Put the smelted master alloy into a quartz tube with a hole at the bottom, and place the quartz tube in an intermediate frequency induction furnace for secondary smelting. When the alloy temperature reaches 1320°C, fill with 99.99% argon and keep the pressure in the furnace. 1.2 atmospheric pressure, the spacing between the protection roller nozzles is 0.3-0.5mm, the molten alloy is sprayed onto the rotating water-co...

Embodiment 2

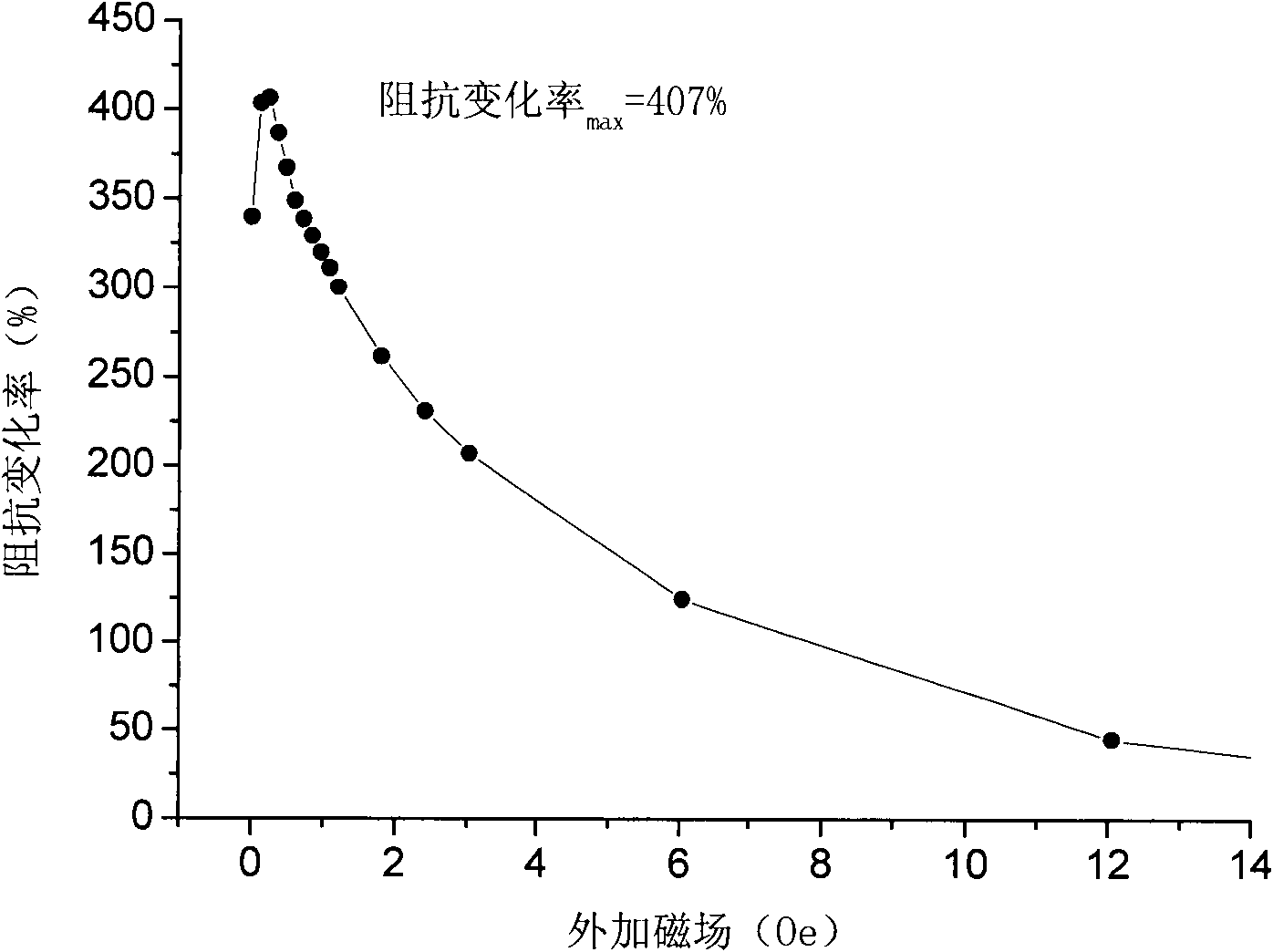

[0025] Embodiment 2, the material composition of this example is composed of Co 64 Fe 3 V 3 Si 10 B 20 , according to the composition of chemical elements, the purity of the raw materials is ≥99.9%, put the prepared raw materials into the vacuum induction melting furnace, vacuumize, when the vacuum degree reaches 0.01Pa, fill with argon gas with a purity of 99.99%, and the air pressure is controlled at 1.2 atmospheric pressure, the melting temperature is about 1250 ℃, the time is 20 minutes, and the master alloy is obtained by cooling with the furnace.

[0026] Put the smelted master alloy into a quartz tube with a hole at the bottom, and place the quartz tube in an intermediate frequency induction furnace for secondary smelting. When the alloy temperature reaches 1350 °C, fill with 99.99% argon and keep the pressure in the furnace. At 1.4 atmospheric pressure, the spacing between the protection roller nozzles is 0.3-0.5mm, the molten alloy is sprayed onto the rotating wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com