Formula and preparation process of transforming agent of organic feed of grain-free biomass

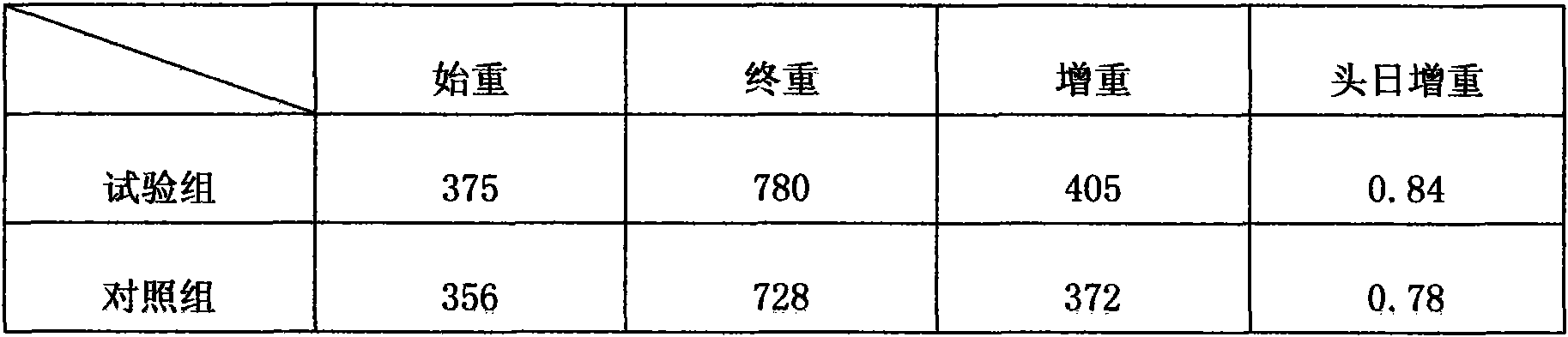

An organic feed and preparation technology, applied in the agricultural field, can solve the problems of insufficient degradation of cellulose, insufficient protein and other elements, waste, etc., and achieve the effect of obvious nutritional value, no residue and toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] see Figure 1-5 , The specific embodiment adopts the following technical scheme: its formula consists of: 80% of alkaline activator, 0.05% of mineral element activator, and 19.95% of biological activator.

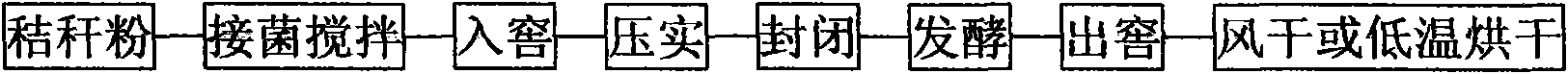

[0028] Its preparation process is:

[0029] 1. The straw should be powdered into 1.2-1.5mm fine bran shape by artificial or mechanical method, destroying the cell structure, so as to increase the contact surface between microorganisms, cellulose and hemicellulose during the straw fermentation process.

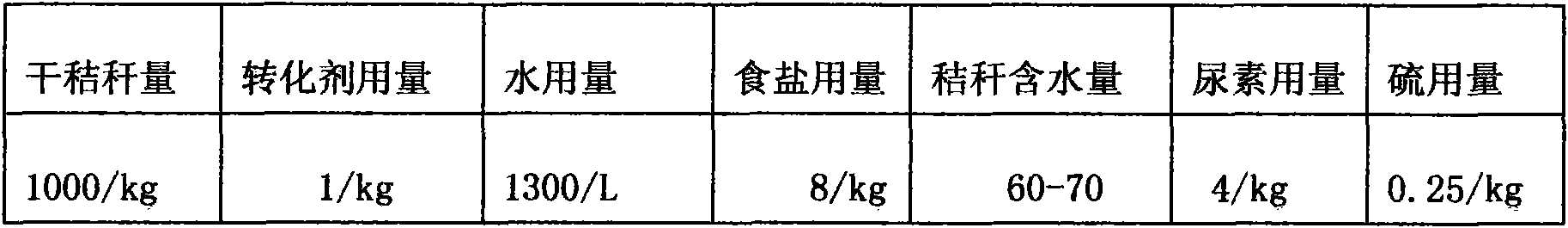

[0030] 2. After dissolving the conversion agent in 1:140 water, add urea and sulfur, the ratio of the two is 16:1 (the conversion value of inorganic nitrogen of urea is 298), stir with grass powder 2:1, step on the cellar and seal it tightly, at 15 --Anaerobic fermentation at 42 degrees Celsius for 5-7 days to become wet feed.

[0031] 3. It can be air-dried or dried at low temperature, and should not exceed 45°C to avoid killing probiotics by high temperature. Bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com