Selective hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst and selective hydrogenation technology, applied in the direction of selective hydrogenation refining, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve high cracking activity, unsuitable carrier, Reduce liquid yield and other problems, achieve the effect of low carbon deposition, good chemical and thermal stability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

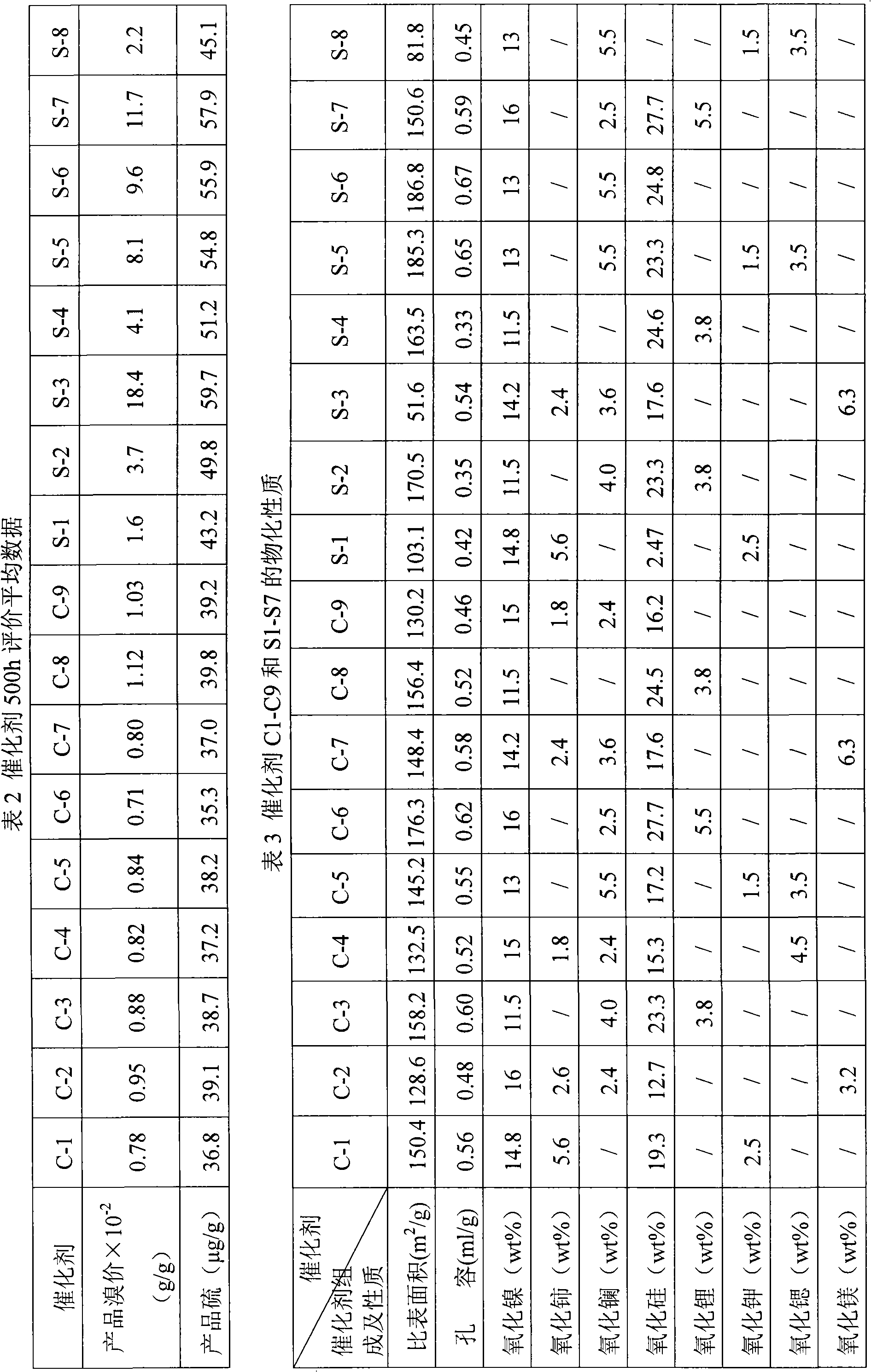

Examples

Embodiment 1

[0053] Configure 2L concentration as 100gAl 2 o 3 / L of sodium metaaluminate solution is placed in the glue tank, the temperature of the glue tank is controlled at 40°C, and 60v% CO is introduced under stirring conditions. 2 The mixed gas of +40v% air, the flow rate of carbon dioxide in the mixed gas is 2Nm 3 / h. When the pH value reaches 10.5, stop feeding the mixed gas, and then age for 25 minutes to obtain pseudo-boehmite slurry.

[0054] Configuration 4L concentration is 100gAl 2 o 3 / L of sodium metaaluminate solution is placed in the gel tank, then add 2L 100gSiO 2 / L of sodium silicate solution, control the temperature of the glue tank at 30°C, and feed 60v% CO 2 Mixed gas of +40v% air, CO in the mixed gas 2 The flow rate is 3Nm 3 / h, the pH at the end point was controlled to be 9.5, and the amorphous silicon-aluminum slurry was obtained by aging for 10 minutes.

[0055] Under the condition of constant stirring, add 3L amorphous silica-alumina slurry to 1L pseu...

Embodiment 2

[0058] The preparation of amorphous silica-alumina was carried out according to Example 1.

[0059] Configure 2L concentration of 150gAl 2 o 3 / L of sodium metaaluminate solution, placed in the gel tank, the temperature of the gel tank is controlled at 35°C, and the concentration of 70v% CO is introduced under stirring conditions. 2 The mixed gas of +30v% air, the flow rate of carbon dioxide in the mixed gas is 4Nm 3 / h, stop feeding the mixed gas when the pH value reaches 10.0, and age for 20 minutes to obtain pseudo-boehmite slurry.

[0060] Under the condition of constant stirring, add 2L of pseudo-boehmite slurry into 3L of amorphous silicon-alumina slurry, control the mixing temperature at 30°C, age for 15min, filter and wash to Na + The content is less than 0.5%, and dried at 120° C. for 9 hours to obtain pseudo-boehmite containing amorphous silica-alumina.

[0061] Mix and knead pseudo-boehmite containing amorphous silicon-alumina with nitric acid, lanthanum nitrate...

Embodiment 3

[0063] The preparation of the pseudo-boehmite slurry was carried out according to Example 1.

[0064] Configure 2L concentration of 130gAl 2 o 3 / L sodium metaaluminate solution is placed in the gel tank, and then add 2L 80gSiO 2 / L of sodium silicate solution, control the reaction temperature at 20°C, and feed 50v% CO 2 Mixed gas of +50v% air, CO in the mixed gas 2 The flow rate is 5Nm 3 / h, the pH at the end point is controlled to be 9.0, and the amorphous silicon-aluminum slurry is obtained by aging for 20 minutes.

[0065] Under the condition of constant stirring, add 1L of pseudo-boehmite slurry and 3L of amorphous silicon-alumina slurry into the gel forming tank, control the mixing temperature at 35°C, age for 15min, filter and wash until Na + The content is less than 0.5%, and dried at 120°C for 8 hours to obtain pseudo-boehmite containing amorphous silica-alumina.

[0066] Pseudo-boehmite containing amorphous silica-alumina is mixed and kneaded with nitric acid, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com