Preparation method for lignosulfonate

A technology of lignosulfonate and lignin, which is applied in the field of pulping waste liquid recycling, can solve the problems of complex process, long production cycle, low production efficiency, etc., and achieve the effect of simple process flow, simplified process and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a kind of preparation method of lignosulfonate, comprises the following steps:

[0031] a) Mixing waste pulping liquor by kraft method and waste pulping liquor by sulfite method to obtain mixed waste liquor, the pH value of the mixed waste liquor is 12-13, and the waste pulping liquor by kraft method includes wood and sodium hydroxide, and the sulfite process pulping waste liquor includes calcium lignosulfonate and reducing sugar;

[0032] b) After raising the temperature of the mixed waste liquid and keeping it warm, the first solution is obtained;

[0033] c) After adjusting the pH value of the first solution to 10.5-11.5, adding an aldehyde compound therein to obtain lignosulfonate after reaction.

[0034] The present invention uses kraft pulping waste liquor and sulfite pulping waste liquor as raw materials to prepare lignosulfonate, wherein, kraft pulping waste liquor refers to the waste liquor produced after kraft pulping , whose main comp...

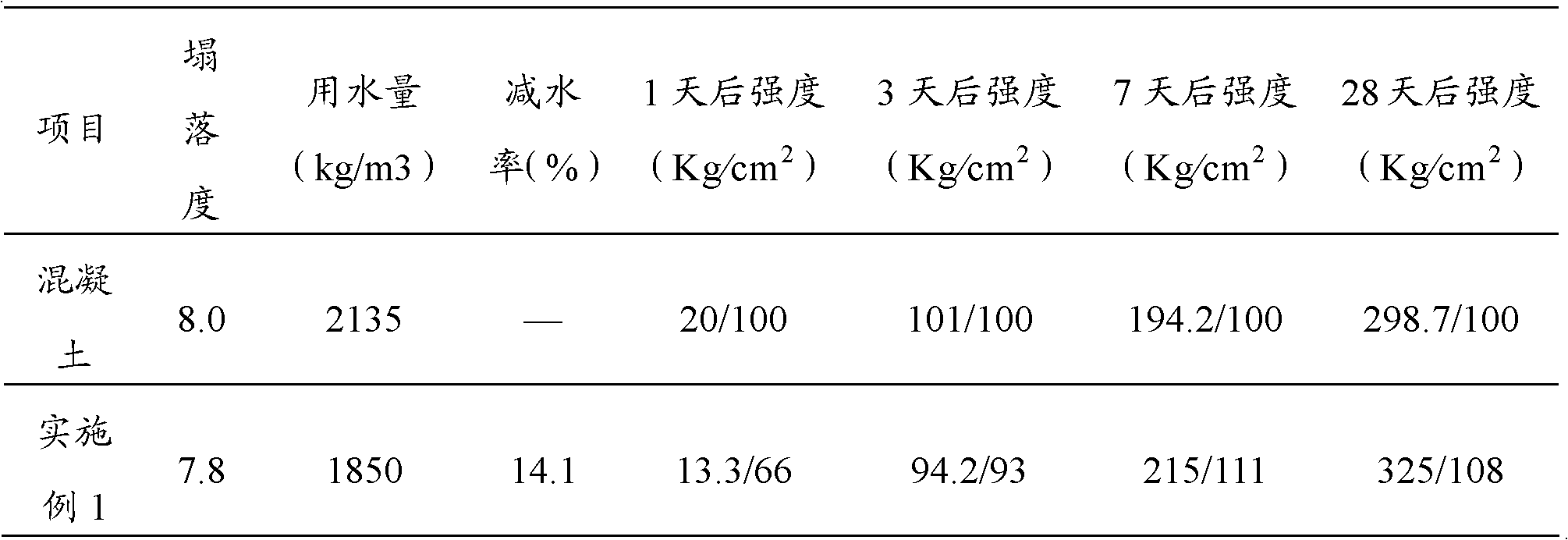

Embodiment 1

[0055] The kraft pulping waste liquid is the waste liquid produced by pulping with rice straw as raw material and sodium hydroxide and sodium sulfide as the cooking liquid. The kraft pulping waste liquid is concentrated, and in the obtained first concentrate The mass content of lignin is 30%;

[0056] Sulphite pulping waste liquid is the waste liquid produced by pulping with rice straw as raw material and calcium bisulfite as cooking liquid. The sulphite pulping waste liquid is concentrated, and the obtained second concentrated liquid is The mass content of calcium lignosulfonate is 60%;

[0057] Mix the first concentrated liquid and the second concentrated liquid so that the pH value of the obtained mixed waste liquid is 12.5; under the condition of stirring, raise the temperature of the mixed waste liquid to 95° C., stir and react for 2 hours, and obtain the first solution, the reducing sugar in the first solution is 4.5%;

[0058] Passing carbon dioxide-rich flue gas into...

Embodiment 2

[0065] Kraft pulping waste liquid is the waste liquid produced by pulping with bamboo as raw material and sodium hydroxide and sodium sulfide as the cooking liquid. The kraft pulping waste liquid is concentrated, and in the obtained first concentrate The mass content of lignin is 35%;

[0066] Sulphite pulping waste liquid is the waste liquid produced by pulping with bamboo as raw material and calcium bisulfite as cooking liquid. The sulphite pulping waste liquid is concentrated, and in the obtained second concentrated liquid The mass content of calcium lignosulfonate is 65%;

[0067] Mix the first concentrated liquid and the second concentrated liquid so that the pH value of the obtained mixed waste liquid is 12.3; under the condition of stirring, the temperature of the mixed waste liquid is raised to 90° C., and stirred for 2 hours to obtain the first solution, the reducing sugar in the first solution is 1%;

[0068] Introduce flue gas rich in carbon dioxide into the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com