Preparation method of super high coercivity and low-Co type Sm-Co nanocrystalline alloy

A nanocrystalline alloy, coercive force technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of small coercive force, weak hard magnetic properties, and few research reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

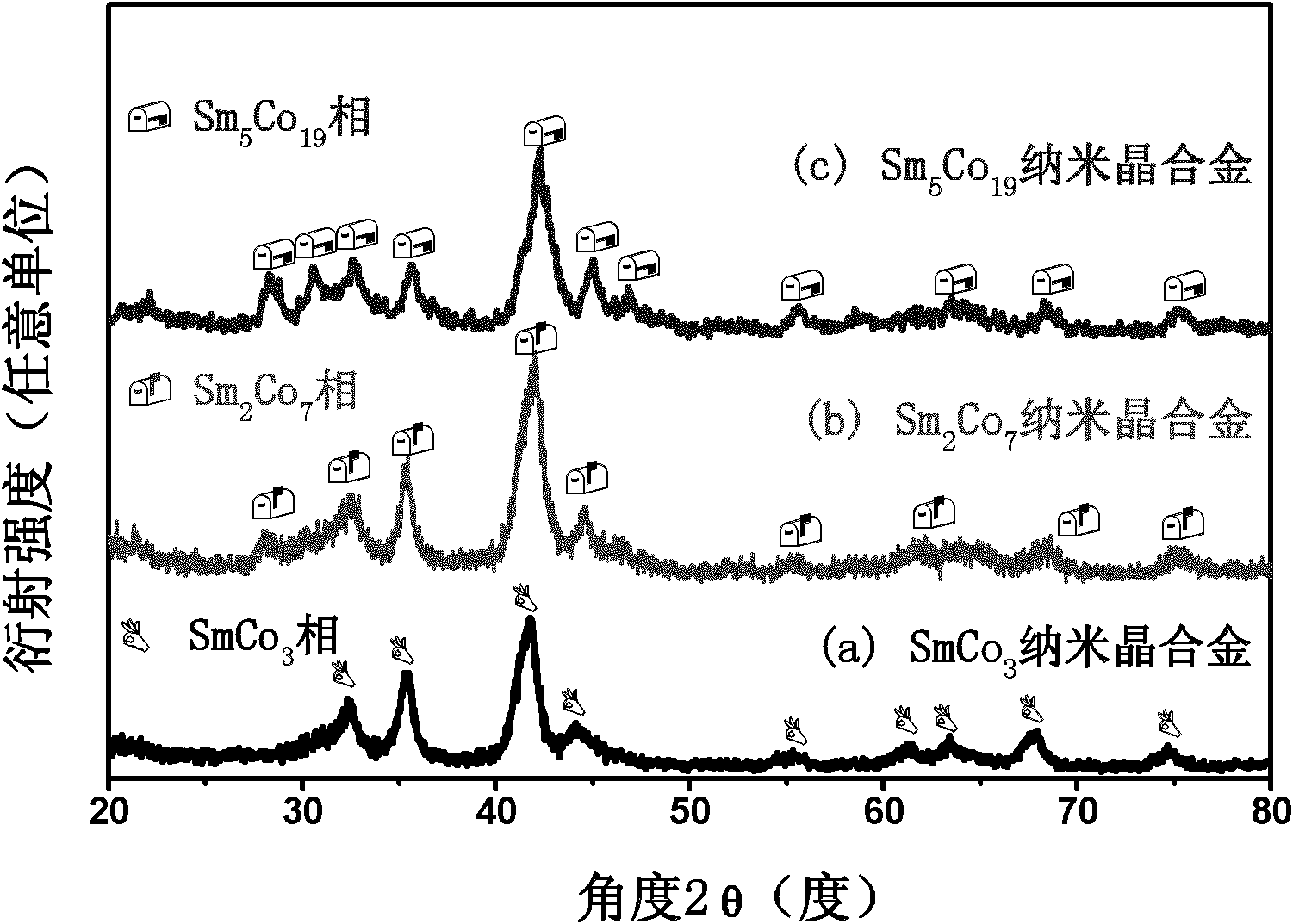

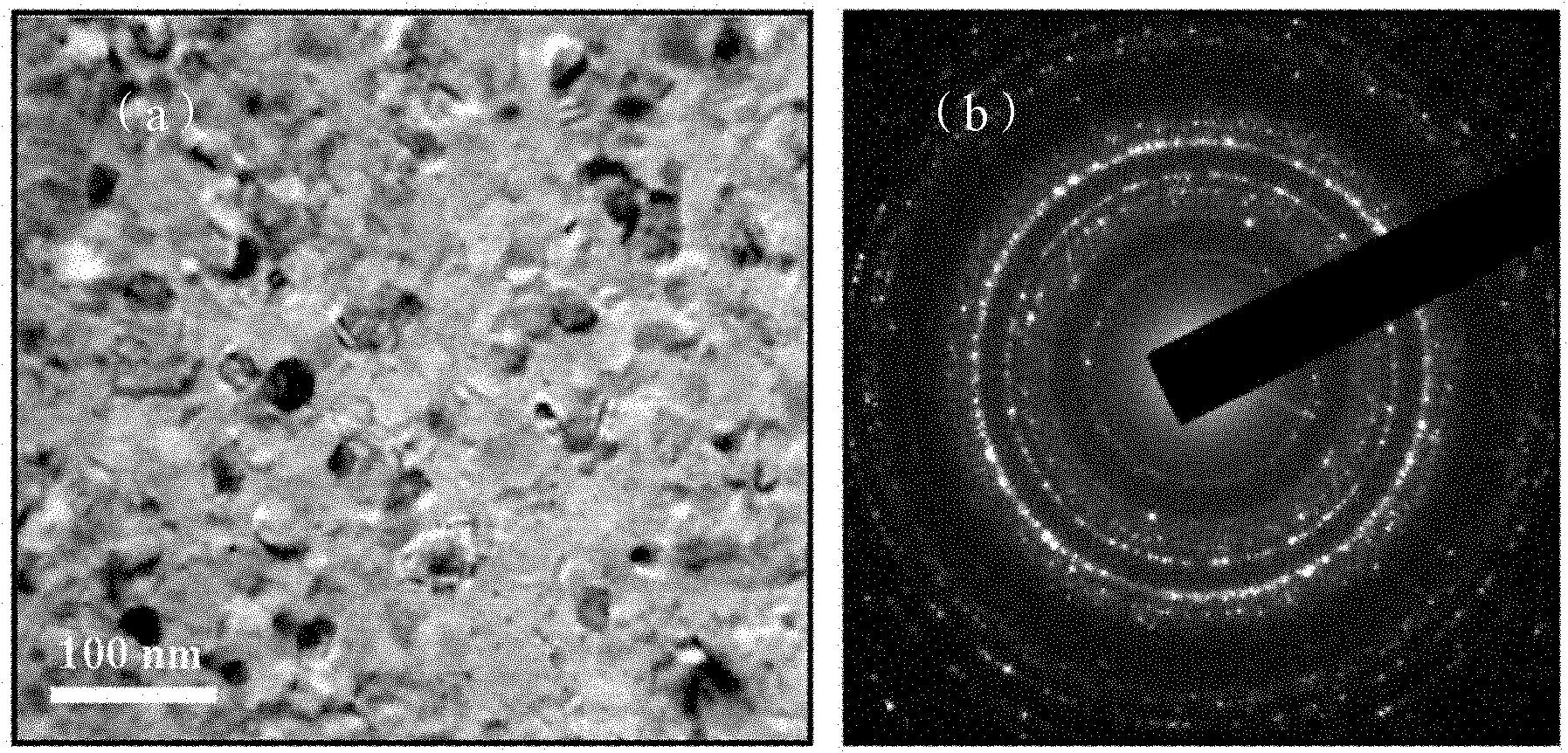

Embodiment 1

[0024] (1) Mix flaky Co with a purity of 99.9% or higher and small pieces of metal Sm with a purity of 99.95% or higher at an atomic ratio of 3:1 (x=3), and coat the small pieces of Sm evenly with the flakes of Co The raw material is then smelted in a cold-wall magnetic levitation eddy current induction furnace to prepare a nominal composition of SmCo 3 The alloy ingot, the alloy ingot is remelted more than 2 times, and the nominal composition is SmCo 3 master alloy ingot;

[0025] (2) SmCo obtained from step (1) 3 The master alloy ingot is placed in a vacuum annealing furnace, and the gas pressure in the furnace is less than 4×10 -3 Pa. Rapidly raise the temperature to 900°C for 30 hours of isothermal homogenization annealing treatment, and then cool to room temperature with the furnace;

[0026] (3) SmCo after homogenization annealing 3 The alloy is crushed into powder particles smaller than 300 μm, and the crushed powder particles are put into a ball milling tank accor...

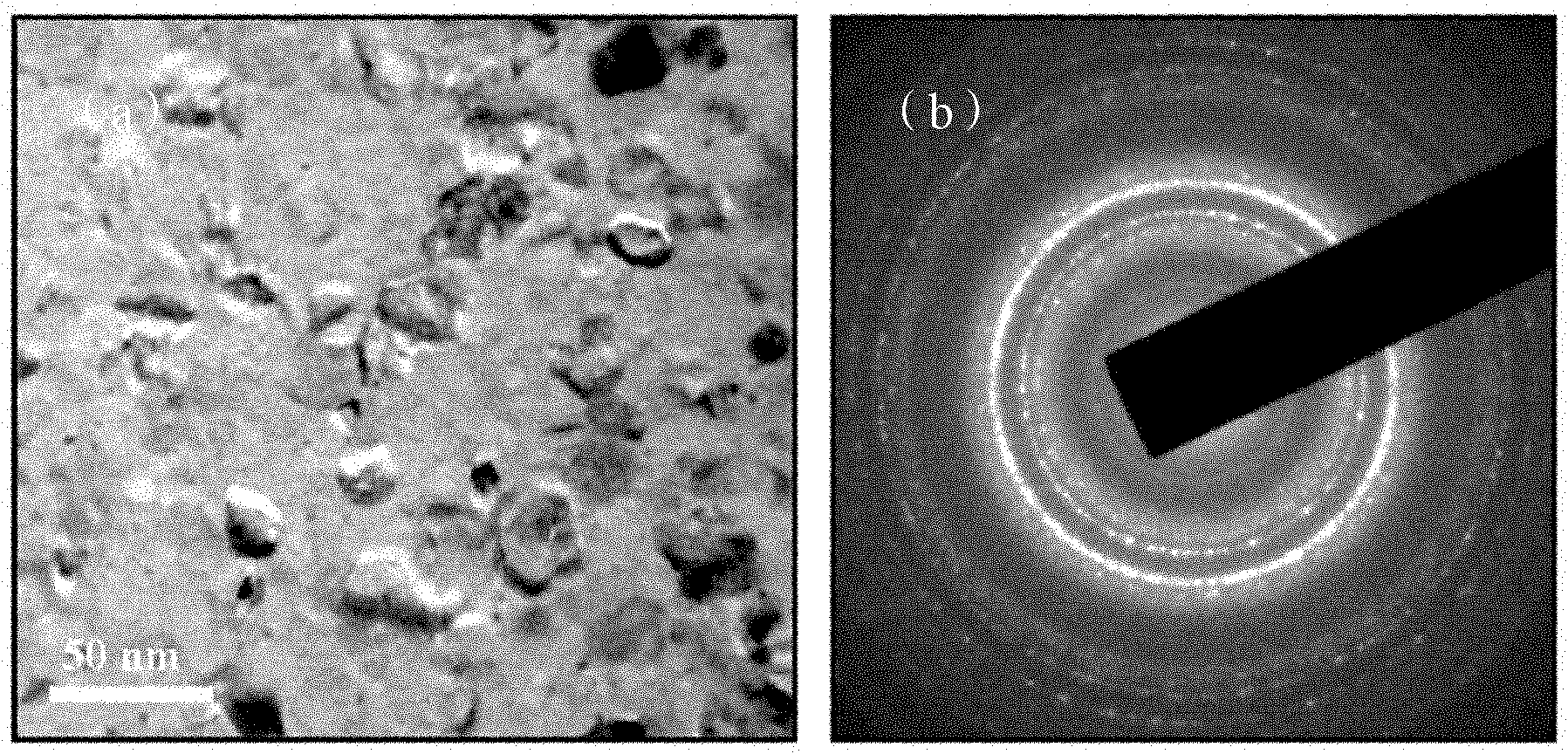

Embodiment 2

[0030] (1) Mix flake-shaped Co with a purity of 99.9% or higher and small pieces of metal Sm with a purity of 99.95% or higher at an atomic ratio of 7:2 (x=3.5), and wrap the flakes of Co evenly around the small pieces of Sm raw material , and then smelted with a cold-wall magnetic levitation eddy current induction furnace to prepare a nominal composition of Sm 2 co 7 The alloy ingot, the alloy ingot is remelted more than 2 times, and the nominal composition is Sm 2 co 7 master alloy ingot;

[0031] (2) Sm obtained from step (1) 2 co 7 The master alloy ingot is placed in a vacuum annealing furnace, and the gas pressure in the furnace is less than 8×10 -3 Pa. Rapidly raise the temperature to 1000°C for 25 hours of isothermal homogenization annealing treatment, and then cool to room temperature with the furnace;

[0032] (3) Sm after homogenization annealing 2 co 7 The alloy is crushed into powder particles smaller than 300 μm, and the crushed powder particles are put i...

Embodiment 3

[0036] (1) Flake-shaped Co with a purity of 99.9% or more and small pieces of metal Sm with a purity of 99.95% or more are mixed at an atomic ratio of 19:5 (x=3.8), and the flakes of Co are uniformly wrapped around the small pieces of Sm The raw material is then smelted in a cold-wall magnetic levitation eddy current induction furnace to prepare a nominal composition of Sm 5 co 19 The alloy ingot, the alloy ingot is remelted more than 2 times, and the nominal composition is Sm 5 co 19 master alloy ingot;

[0037] (2) Sm obtained from step (1) 5 co 19 The master alloy ingot is placed in a vacuum annealing furnace, and the gas pressure in the furnace is less than 1×10 -2 Pa. Rapidly raise the temperature to 1200°C for 20 hours of isothermal homogenization annealing treatment, and then cool to room temperature with the furnace;

[0038] (3) Sm after homogenization annealing 5 co 19 The alloy is crushed into powder particles smaller than 300 μm, and the crushed powder par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com