Double-layer transparent electrode on P type GaN (gallium nitride)

A technology of transparent electrodes and transparent conductive layers, which is applied in the field of electrodes, can solve problems such as difficulty in uniform current diffusion, poor stability, and ITO toxicity, and achieve the effects of uniform current diffusion, good thermal stability, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

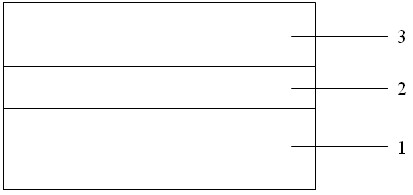

[0018] On the P-type GaN layer 1, an ITO thin film 2 as the first transparent electrode layer and a ZnO-based thin film 3 as the second transparent electrode layer are sequentially deposited by magnetron sputtering technology from bottom to top. GaN-based LEDs using ITO and ZnO-based double-layer electrodes on P-type GaN can increase their luminous efficiency by 1-5%.

Embodiment 2

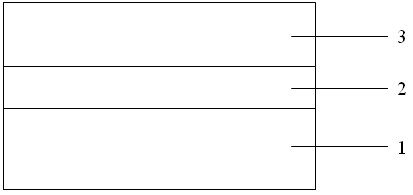

[0020] On the P-type GaN layer 1, an ITO thin film 2 as the first transparent electrode layer and a ZnO-based thin film 3 as the second transparent electrode layer are sequentially deposited by evaporation technology from bottom to top. GaN-based LEDs using ITO and ZnO-based double-layer electrodes on P-type GaN can increase their luminous efficiency by 1-4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com