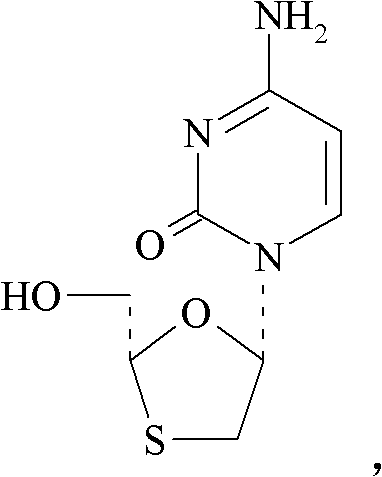

Easy-dissolution lamivudine tablet and preparation method thereof

A technology of lamivudine tablets and lamivudine, which is applied in pill delivery, digestive system, antiviral agents, etc., can solve the problems of differences in bioavailability and drug dissolution, and achieve high dissolution and bioavailability The effect of high precision and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

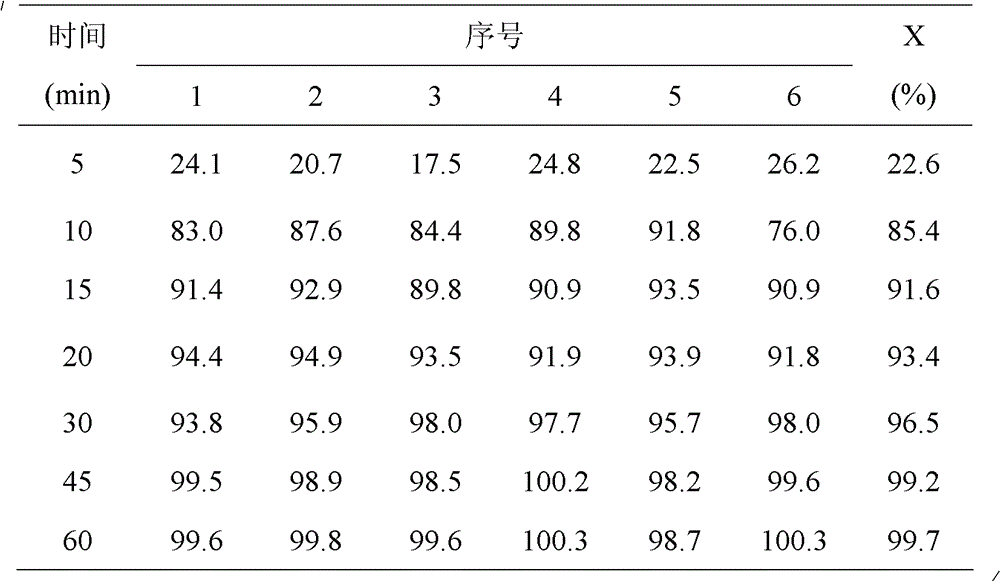

Examples

Embodiment 1

[0030] Get lamivudine 100g, microcrystalline cellulose 100g, sodium carboxymethyl starch 6.5g, magnesium stearate 2.1g, 2% hydroxypropylmethylcellulose (E15) aqueous solution 105g.

[0031] The preparation method of lamivudine tablet comprises the following processing steps:

[0032] (1) take above-mentioned parts by weight lamivudine, microcrystalline cellulose, sodium carboxymethyl starch, magnesium stearate and cross 100 mesh sieves;

[0033] (2) Weigh hydroxypropyl methylcellulose, add purified water (mass ratio 2: 98) and stir to make the hydroxypropyl methylcellulose mixed pulp of the above-mentioned 2% by weight:

[0034] (3) The sodium carboxymethyl starch and the microcrystalline cellulose are uniformly mixed by equal addition method, and then the lamivudine is mixed with it.

[0035] (4) Add the prepared 2% hydroxypropyl methylcellulose mixed pulp as a binder and add to step (3) to make a soft material, pass through a 24-mesh sieve for granulation. Place in an oven...

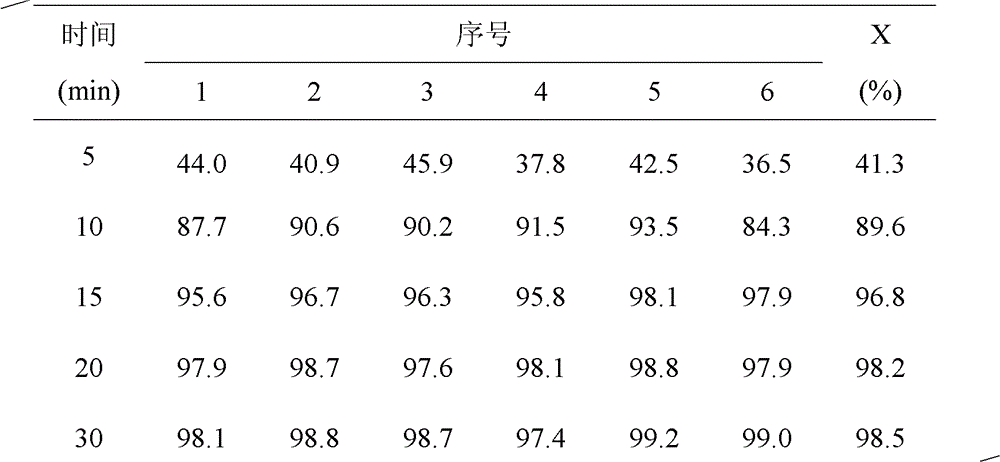

Embodiment 2

[0040] Take lamivudine 100g, microcrystalline cellulose 95g, sodium carboxymethyl starch 5g, magnesium stearate 1.5g, 2% hydroxypropylmethylcellulose (E15) aqueous solution 90g. 1000 lamivudine tablets can be produced, each containing 100 mg of active ingredient lamivudine.

[0041] All the other are with embodiment 1.

Embodiment 3

[0043] Get lamivudine 100g, microcrystalline cellulose 105g, sodium carboxymethyl starch 8g, magnesium stearate 3g, 2% hydroxypropylmethylcellulose (E15) aqueous solution 120g. 1000 lamivudine tablets can be produced, each containing 100 mg of active ingredient lamivudine.

[0044] All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com