Metal implant and surface treatment method thereof

A technology of surface treatment and implants, applied in medical science, prosthesis, etc., can solve problems such as damage, reduce the probability of damage, and promote the effect of calcium phosphate deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

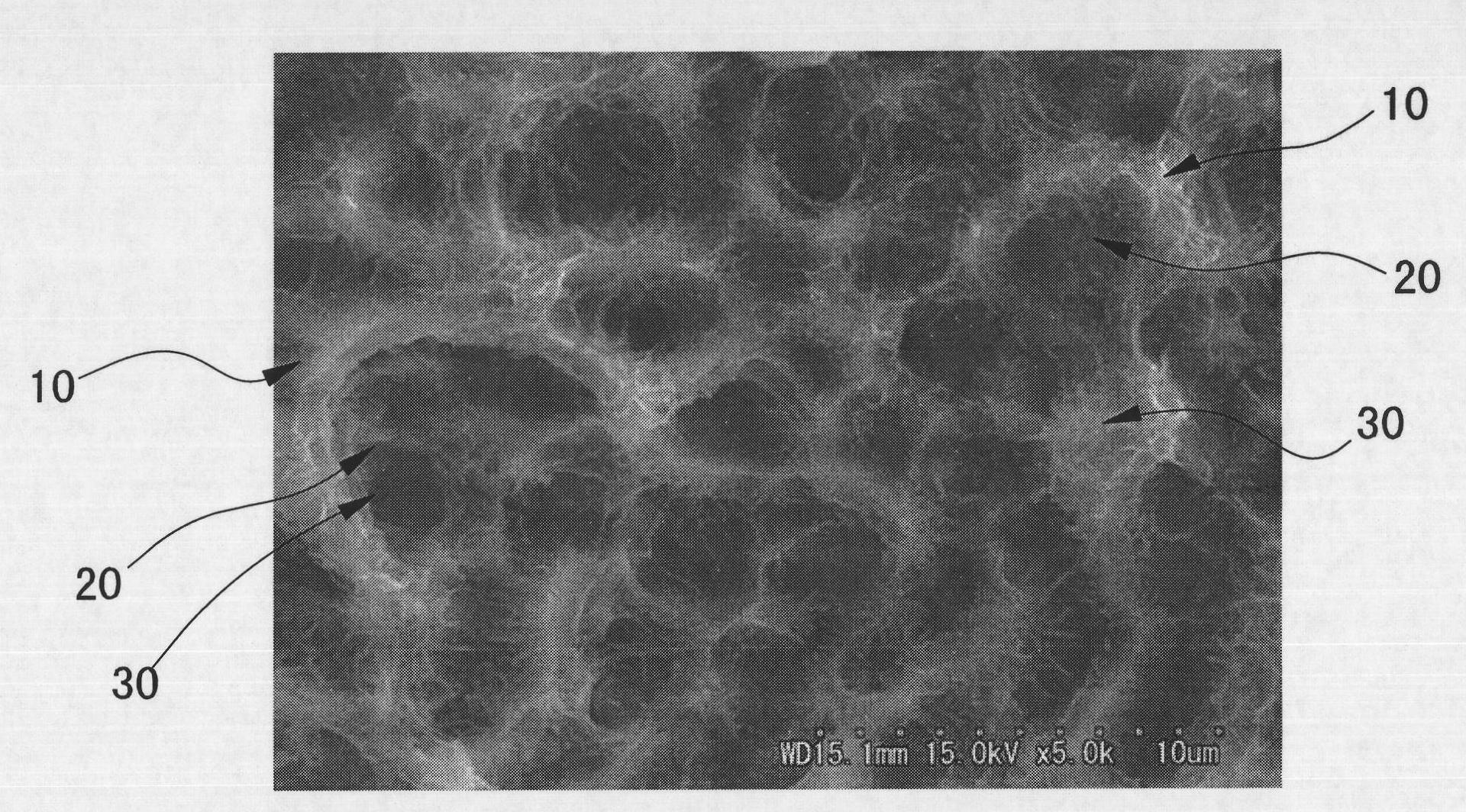

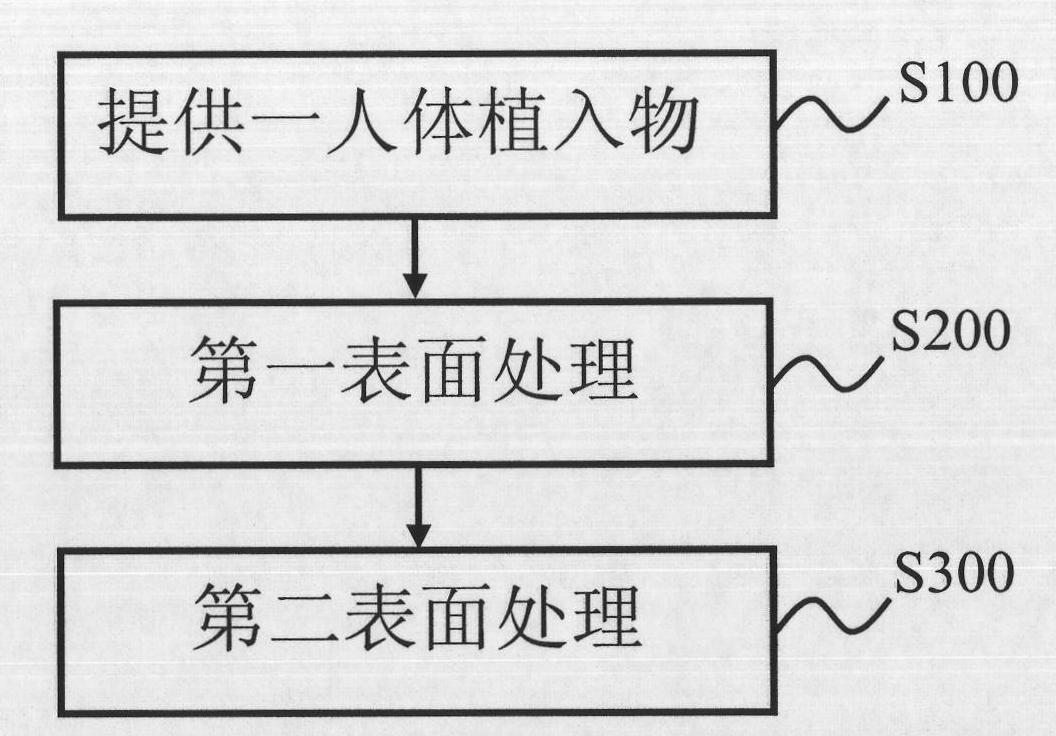

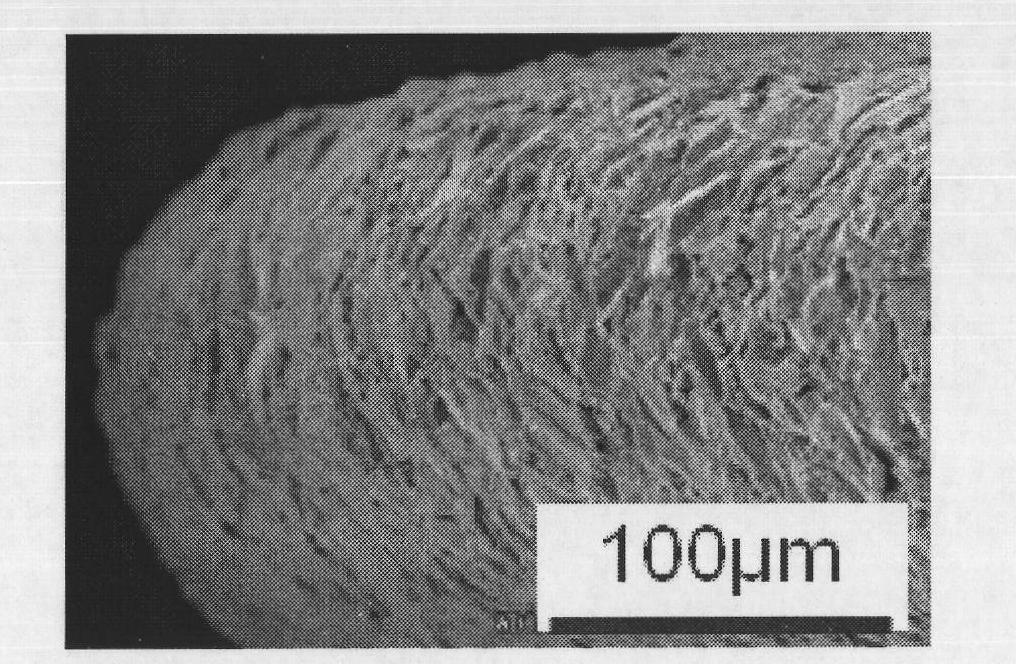

[0054] The metal implant in Example 1 is an example of a titanium metal. After the surface of the titanium metal is subjected to sandblasting (the first surface treatment) with 100 microns of alumina sand, the surface of the titanium metal will produce holes with a diameter of about 10 microns. After that, place the titanium metal in 5M sodium hydroxide aqueous solution for 4 hours, then place it in 50mM hydrochloric acid aqueous solution HCl(aq) for 3 hours, and finally heat-treat it at 600°C for 1 hour (second surface treatment), After the first surface treatment is combined with the second surface treatment, the surface structure result of the titanium metal is shown in FIG. 3 .

[0055] Please refer to Figure 3, Figure 3A and Figure 3B Be respectively the surface SEM figure of the metal implant of embodiment 1 when magnification is 500 times and 2500 times, by Figure 3A and Figure 3B It can be seen that the surface of the metal implant contains a plurality of micron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com