Air-purifying particle composition and preparation method of air-purifying particle composition

An air purification and composition technology, applied in the field of inorganic composite air purification materials and their preparation, can solve the problems of limited long-term treatment of indoor pollutants, short life of negative ions, etc., and achieves good catalysis, strong air purification ability, and convenient and direct use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

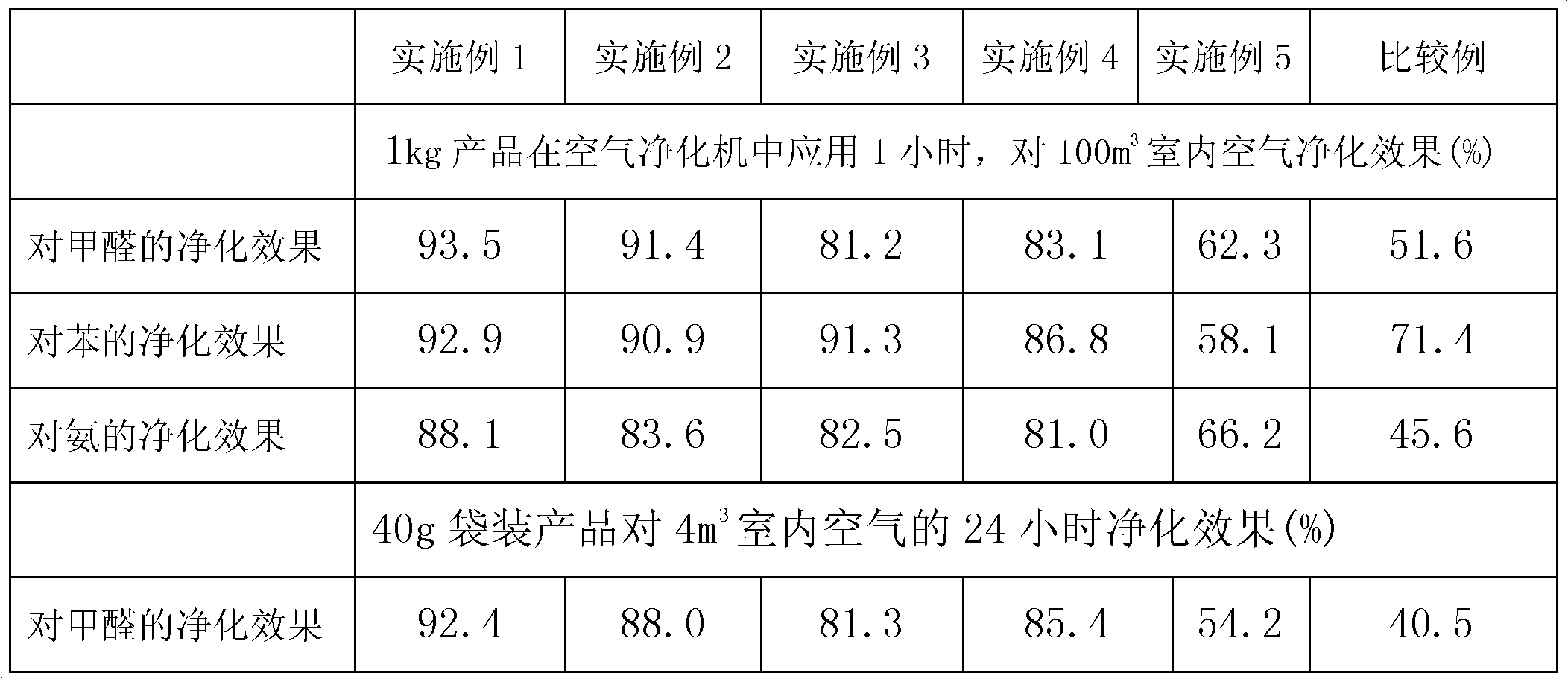

Embodiment 1

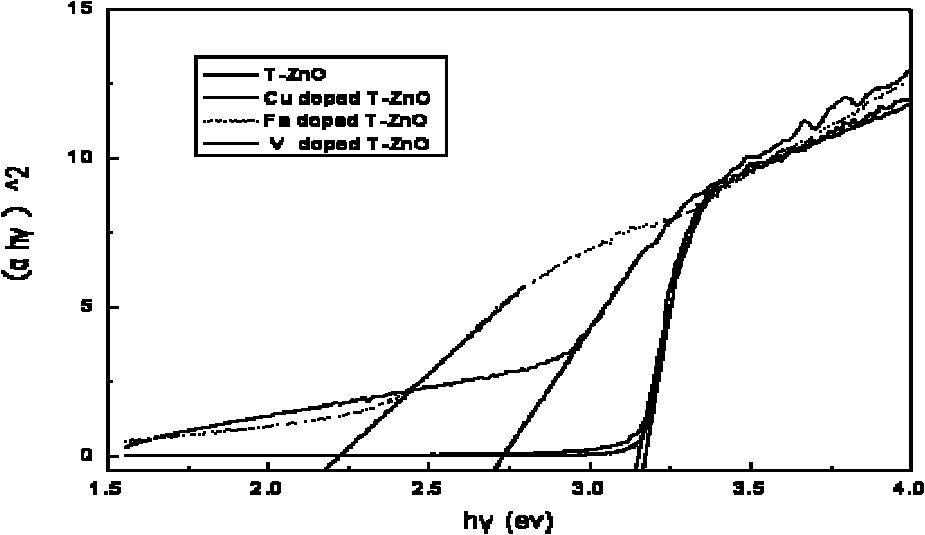

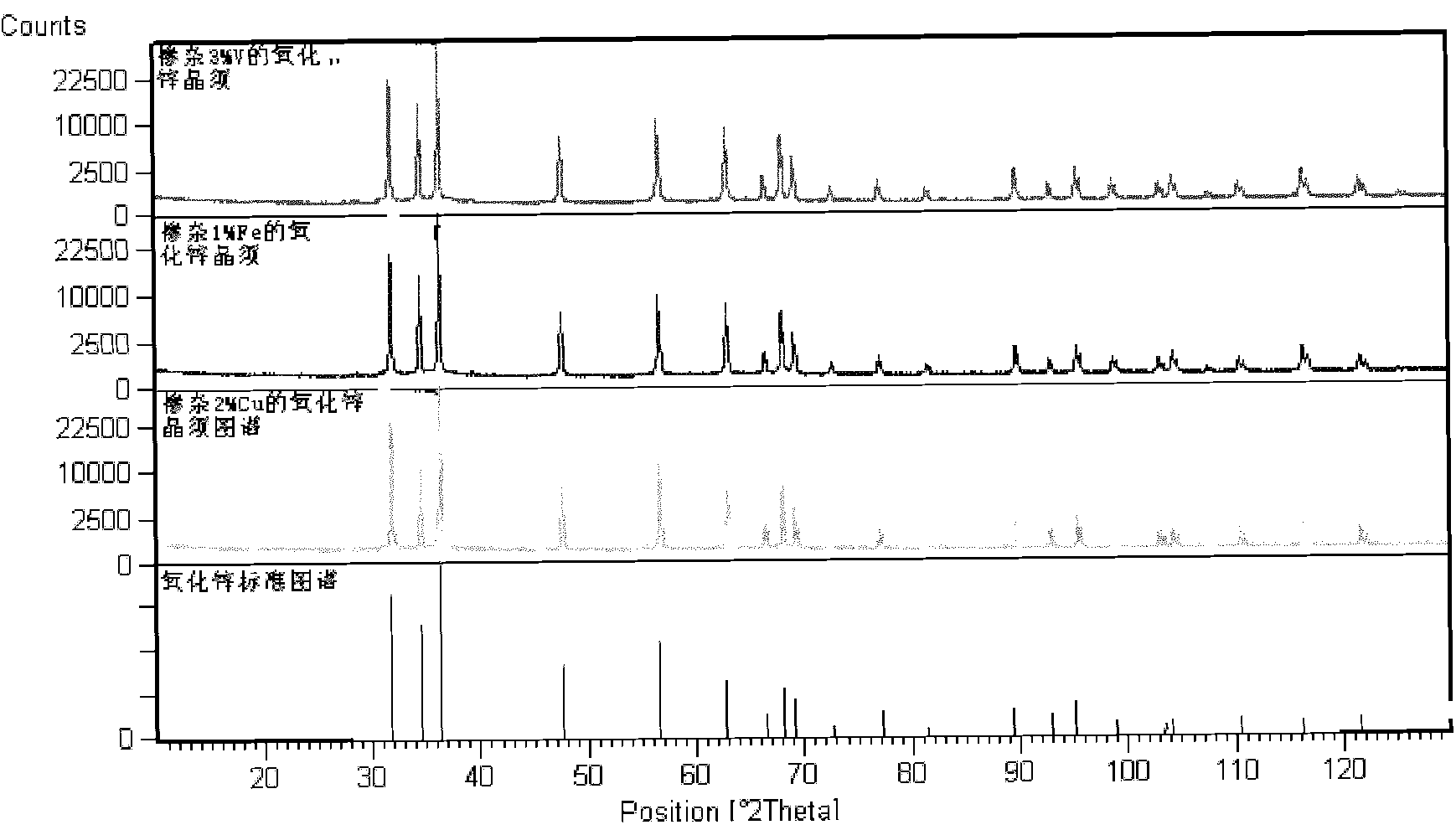

[0032] An air-purifying granule composition contains components and weight ratios: 80 parts of tetrapod-like zinc oxide whiskers, 15 parts of 13X molecular sieve, and 5 parts of magnesium phosphate. Among them, 80 parts by weight of tetrapod ZnO whiskers are doped with 1 part by weight of Fe 3+ ion. It is made by:

[0033] 63 weights of 5mm wide, 0.2mm thick zinc strips, and Fe-containing 3+ 1 part weight of salt is placed in the furnace, and then sintered in a hydrogen atmosphere at 800 ° C for 40 minutes to obtain a length of 10-40 μm, a root diameter of 0.5-10 μm, and 1 part weight of Fe doped in the lattice. 3+ 80 parts by weight of ionic tetraacicular zinc oxide whiskers.

[0034] Then 80 parts by weight of the lattice is doped with 1 part by weight of Fe 3+ Ionic four-acicular zinc oxide whiskers, 15 parts by weight of 13X molecular sieve and 5 parts by weight of magnesium phosphate, after mixing uniformly in a mixing mixer, granulate into balls with a particle diame...

Embodiment 2

[0036] An air-purifying granule composition contains the following components and weight ratio: 60 parts of tetrapod-shaped zinc oxide whiskers, 33 parts of 13X molecular sieve, and 7 parts of magnesium phosphate. Among them, 2 parts by weight of Cu are doped in the crystal lattice of 60 parts by weight of four-needle ZnO whiskers 2+ ion. It is made by:

[0037] 46 weights of 4mm wide, 0.15mm thick zinc strip, and Cu 2+ Put 2 parts by weight of salt in the furnace, and then sinter in a hydrogen atmosphere at 750°C for 60 minutes to obtain 10-40 μm in length, 0.5-10 μm in root diameter, doped with 2 parts by weight in the lattice. Cu 2+ 60 parts by weight of ionic tetraacicular zinc oxide whiskers.

[0038] Then 60 parts by weight of the lattice is doped with 2 parts by weight of Cu 2+ Ionic four-acicular zinc oxide whiskers, 33 parts by weight of 13X molecular sieve and 7 parts by weight of magnesium phosphate, after mixing uniformly in a mixing mixer, granulate into ball...

Embodiment 3

[0040] An air-purifying granule composition contains the following components and weight ratio: 50 parts of tetrapod-like zinc oxide whiskers, 40 parts of 13X molecular sieve, and 10 parts of magnesium phosphate. Among them, 50 parts by weight of tetrapod ZnO whiskers are doped with 3 parts by weight of V 5+ ion. It is made by:

[0041] 37 weights of 6mm wide, 0.25mm thick zinc strip, and containing V 5+ Put 3 parts by weight of salt in the furnace, and then sinter in a hydrogen atmosphere at 900°C for 30 minutes to obtain 50 parts by weight of doped crystal lattice with a length of 10-40 μm and a root diameter of 0.5-10 μm. Tetraacicular ZnO whiskers.

[0042] Then 50 parts by weight of the lattice is doped with 3 parts by weight of V 5+ Ionic four-acicular zinc oxide whiskers, 40 parts by weight of 13X molecular sieve and 10 parts by weight of magnesium phosphate, after mixing uniformly in a mixing mixer, granulate into balls with a particle size of 2-5mm in a granulator...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com