Method for synthesizing PdPt/graphene nano electrical catalyst in one step by microwave process

An electrocatalyst and graphene technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as long time and complexity, and achieve improved efficiency, Improve the effect of uniform distribution and outstanding mechanical properties

Inactive Publication Date: 2011-08-17

NANJING NORMAL UNIVERSITY

View PDF1 Cites 47 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The above method is more complicated and takes a long time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0031] Example 2

Embodiment 2

[0033] Example 3

Embodiment 3

[0035] Comparative example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Login to View More

Abstract

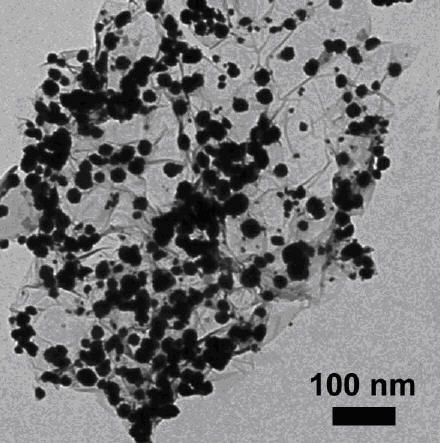

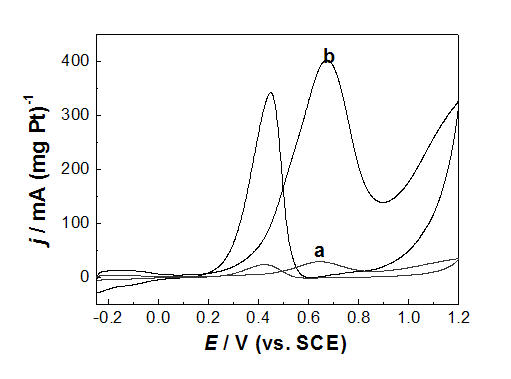

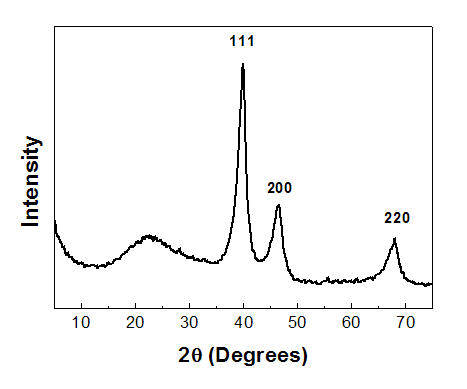

The invention discloses a method for synthesizing a PdPt / graphene nano electrical catalyst in one step by a microwave process, which comprises: dispersing graphene oxide in aqueous solution of quaternary ammonium salt surfactant through ultrasonic waves, adding solution of a soluble Pd II salt or PtII salt, fully and uniformly mixing, regulating the pH value of mixed solution, adding a reducer, uniformly mixing, reacting under radiation of microwaves to reduce palladium and platinum metal ions and graphene oxide, and cooling, washing and drying the reactants to obtain the PdPt / graphene nano electrical catalyst. The method has the characteristics of energy conservation, environmental protection, quickness, simple process and the like. The obtained PdPt / graphene nano electrical catalyst hasa high electric catalysis performance for the electrochemical oxidization of methanol.

Description

technical field [0001] The invention relates to a preparation method of a nanometer material, in particular to a preparation method of a PdPt / graphene nanometer electrocatalyst, and belongs to the technical field of nanocatalyst preparation and the technical field of electrochemical energy. Background technique [0002] In direct methanol fuel cells ( DMFC ), the anode catalysts commonly used are carbon-supported Pt-based catalysts. However, the price of metal Pt is expensive, and the intermediate products of methanol oxidation (mainly CO, etc.) are easy to poison it, resulting in a decrease in the activity of the catalyst (Lamy C, Lima A, LeRhun V, Delime F, Coutanceau C, Léger JM. J . Power Sources 2002, 105, 283.). In order to overcome the above shortcomings, many studies have introduced other metals and platinum to form bimetallic catalysts to alleviate the CO poisoning phenomenon, thereby improving the utilization rate of Pt and the performance of the catalyst. The Pd...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B01J23/44B01J37/34B01J37/16H01M4/92B82Y40/00

CPCY02E60/50

Inventor 张卉蔡称心吴萍

Owner NANJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com