Method for treating ultrahigh-concentration organic industrial wastewater

A technology of industrial waste water and treatment method, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, aerobic and anaerobic process treatment, etc., to achieve low operating cost, reduce COD concentration, and good treatment effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

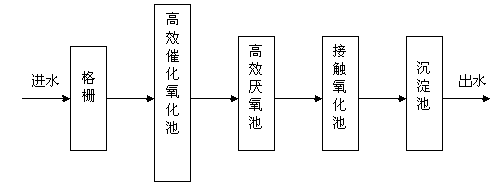

[0018] like figure 1 As shown, the process flow of the present invention is: grid filtration→high-efficiency catalytic oxidation reaction→high-efficiency anaerobic reaction→contact oxidation reaction→sedimentation in sedimentation tank→standard effluent discharge.

[0019] The detailed steps are:

[0020] (1) High-efficiency catalytic oxidation reaction. Under the action of the improved catalytic carrier and oxidant, organic impurity molecules in wastewater undergo high-density catalytic redox reaction and coagulation to degrade organic pollutants; It is carried out under the following conditions, the weight ratio of waste water to the improved catalytic carrier and oxidant is 10:2:1, the pH is 10, and the hydraulic retention time is 0.5h; the improved catalytic carrier includes the following components in weight ratio, TiO 2 50 parts, 10 parts of zeolite, 10 parts of shells, 10 parts of steel slag, 20 parts of cinder; the oxidizing agent includes the following weight ratio ...

Embodiment 2

[0024] A method for treating ultra-high concentration organic industrial wastewater, the steps are as follows,

[0025] (1) High-efficiency catalytic oxidation reaction. Under the action of the improved catalytic carrier and oxidant, organic impurity molecules in wastewater undergo high-density catalytic redox reaction and coagulation to degrade organic pollutants; Under the following conditions, the weight ratio of wastewater to the improved catalytic carrier and oxidant is 100:2:1, the pH is 5, and the hydraulic retention time is 2h; the improved catalytic carrier includes the following components in weight ratio, TiO 2 99 parts, 0.2 part of zeolite, 0.2 part of shell, 0.3 part of steel slag, 0.3 part of cinder; the oxidizing agent includes the following components in weight ratio, KMnO 4 30 parts, FeSO 4 40 parts, Na 2 o 2 30 servings.

[0026] (2) High-efficiency anaerobic reaction, the anaerobic reaction is carried out in the anaerobic reactor to realize the granu...

Embodiment 3

[0029] A method for treating ultra-high concentration organic industrial wastewater, the steps are as follows,

[0030] (1) High-efficiency catalytic oxidation reaction. Under the action of the improved catalytic carrier and oxidant, organic impurity molecules in wastewater undergo high-density catalytic redox reaction and coagulation to degrade organic pollutants; Under the following conditions, the weight ratio of wastewater to the improved catalytic carrier and oxidant is 55:2:1, the pH is 7.5, and the hydraulic retention time is 1h; the improved catalytic carrier includes the following components in weight ratio, TiO 2 75 parts, 5 parts of zeolite, 5 parts of shells, 5 parts of steel slag, 10 parts of coal slag; the oxidizing agent includes the following components by weight ratio, KMnO 4 40 parts, FeSO 4 30 parts, Na 2 o 2 30 servings.

[0031] (2) High-efficiency anaerobic reaction, the anaerobic reaction is carried out in the anaerobic reactor to realize the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com