Process and system for carrying out high-efficiency denitrification and dephosphorization treatment on urban sewage

A technology for denitrification and dephosphorization of urban sewage, applied in multi-stage water/sewage treatment, water/sludge/sewage treatment, energy wastewater treatment, etc. Depth of nitrogen and phosphorus removal, increase of floor area and investment, etc., to achieve the effect of simple and feasible equipment, improvement of phosphorus removal capacity, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

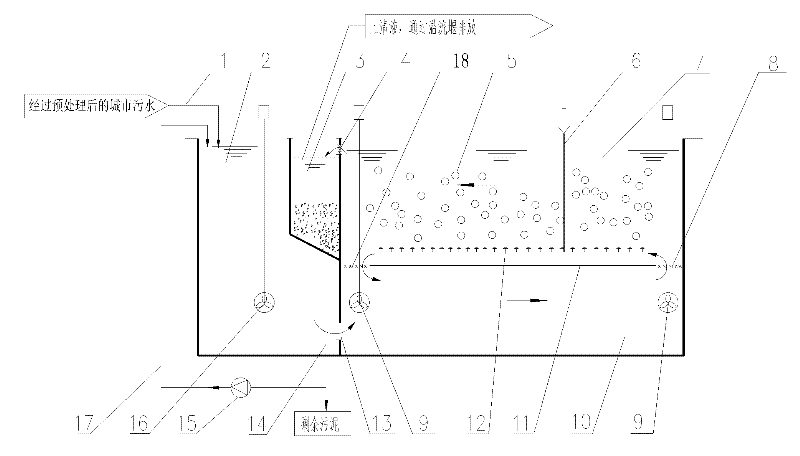

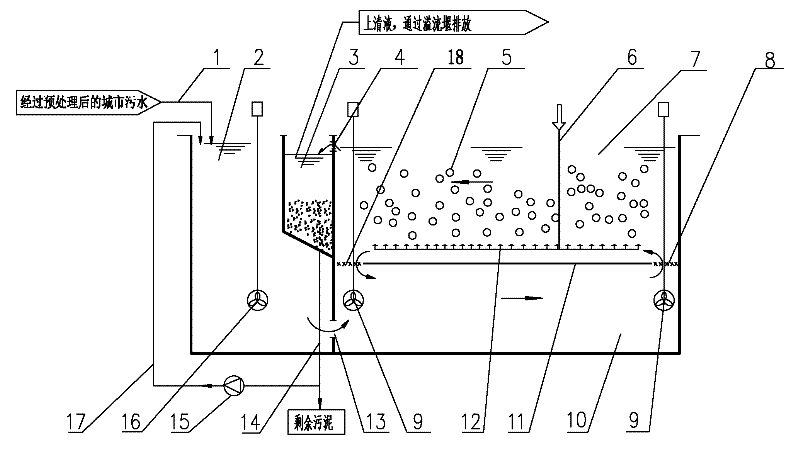

[0031] Such as figure 1 As shown, a treatment process for efficient denitrification and phosphorus removal of urban sewage, which includes the following steps: the pretreated urban sewage (wastewater) directly enters the anaerobic pool for anaerobic hydrolysis, and then enters the anoxic pool and the aerobic pool denitrification, nitrification and biological aerobic degradation; finally enter the sedimentation tank for solid-liquid separation and discharge.

[0032] The pretreatment includes: intercepting the floating matter with a grid, and carrying out pretreatment such as sedimentation of part of the inorganic suspended particles in the urban sewage by a grit chamber.

[0033] The municipal waste water refers to the general term for the sewage discharged into the urban sewage system. In combined sewer systems, production wastewater and retained stormwater are also included. Urban sewage mainly includes domestic sewage and industrial sewage, collected by the urban drainage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com