Inverted mounting LED chip based on double-faced shrinkage pool substrate and component gradual change buffer layer

A LED chip and component gradient technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of lattice mismatch between sapphire substrate and GaN emission layer, and unsatisfactory interface characteristics, so as to increase the range of growth stress , fewer dislocation defects, and the effect of reducing the difference in refractive index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

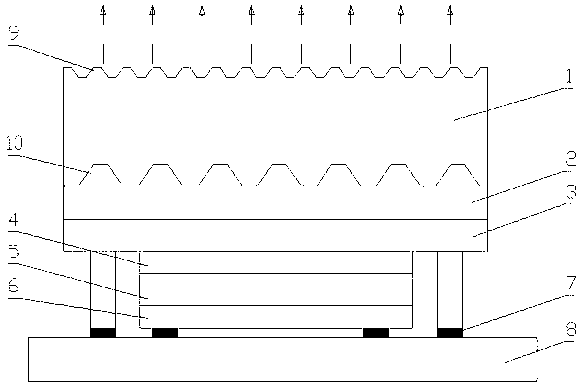

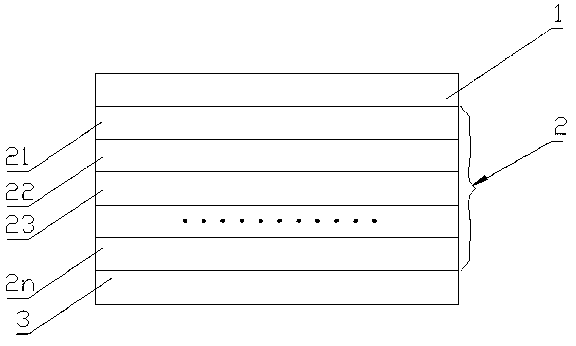

[0023] figure 1 It is a schematic structural diagram of a flip-chip LED chip based on a double-sided concave hole substrate and a composition-graded buffer layer, figure 2 for Al x Ga 1-x The schematic diagram of the structure of the N-component graded buffer layer is shown in the figure. An LED chip based on a double-sided concave hole substrate and a composition-graded buffer layer, the LED chip is composed of a sapphire substrate 1, an Al x Ga 1-x N composition graded buffer layer 2, n-type GaN epitaxial layer 3, InGaN / GaN multiple quantum well 4, p-type GaN layer 5, transparent ITO conductive film 6, flip-chip welding electrode 7 and silicon substrate 8 with good conductivity . The upper surface of the sapphire substrate 1 is uniformly provided with m concave holes I9, wherein m satisfies: 10 2 ≤m≤10 4 , the lower surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com