Multi-functional high-efficiency energy-saving chlorine dioxide generator

A chlorine dioxide, high-efficiency and energy-saving technology, applied in the direction of chlorine dioxide, chemical industry, sustainable manufacturing/processing, etc., can solve the problems of high power consumption and safety hazards, no treatment effect of residual chlorine, low conversion rate of chlorine dioxide, etc. problem, to achieve the effect of low production cost, small occupied area and fast response rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

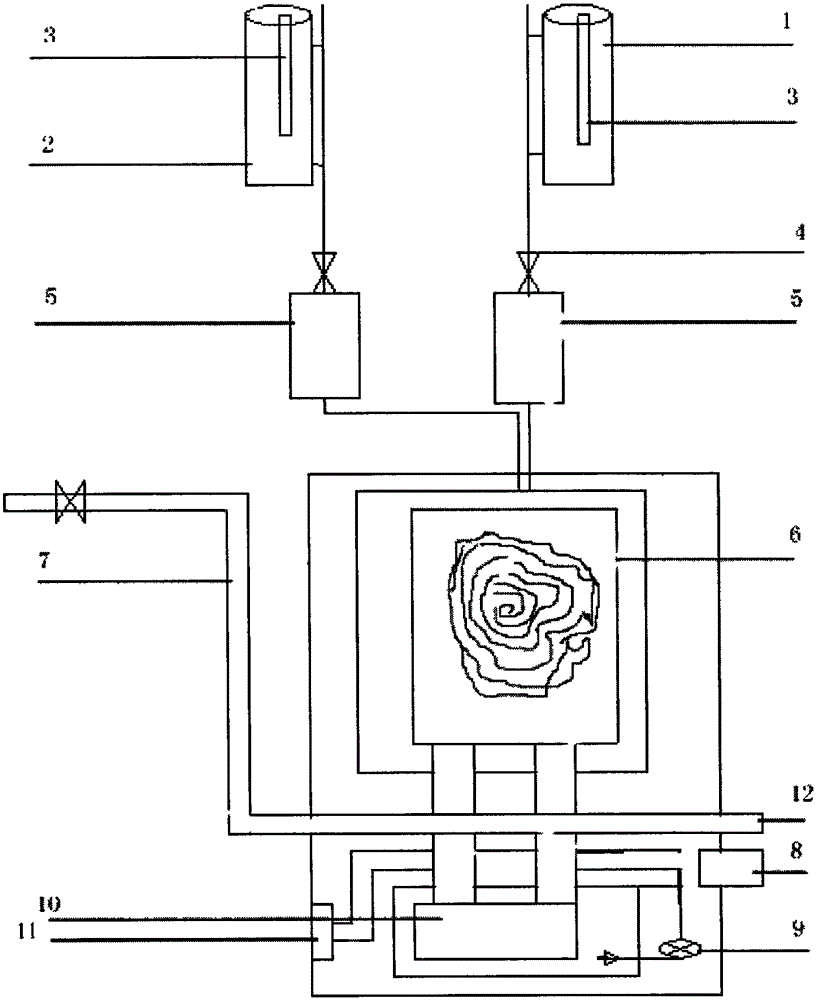

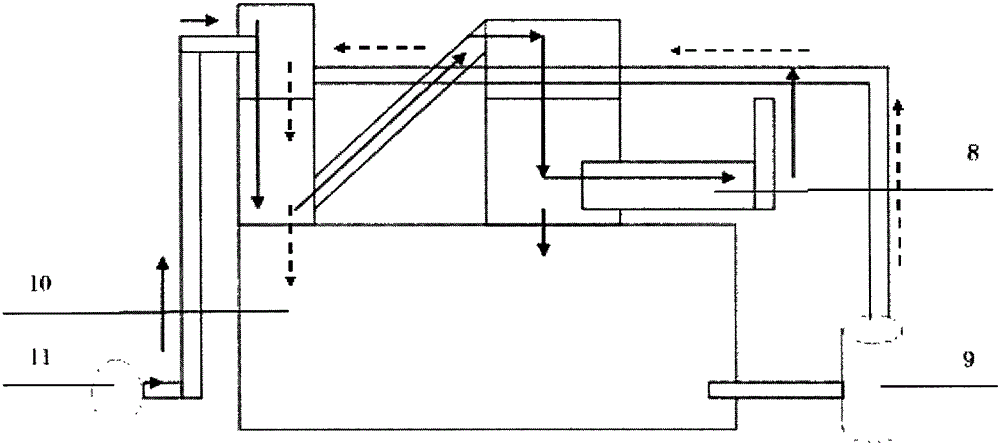

[0019] Such as figure 1 As shown, the raw material feeding barrel perpendicular to the 3-meter height of the chlorine dioxide generator is set outdoors, and the sodium chlorate solution with a concentration of 1 to 20% is injected into the sodium chlorate feeding barrel 1, and the acid solution feeding barrel 2 Inject a hydrochloric acid solution with a concentration of 1 to 20%. After being heated by the heating rod 3, the temperature of the hydrochloric acid is controlled at 50°C, and the temperature of the sodium chlorate is controlled at 80°C. The feed ratio volume ratio of aqueous solution and concentrated hydrochloric acid is 1:0.95. Under the action of gravity, the hydrochloric acid solution and the sodium chlorate solution enter into the PCV intestinal reactor 6 with a pipe diameter of 40 mm and a pipe length of 3000 mm, and they are repeatedly contacted when flowing through the intestinal reactor 6 to carry out a chemical reaction to form High-concentration, high-pur...

Embodiment 2

[0021] Such as figure 1 As shown, the raw material feeding barrel perpendicular to the chlorine dioxide generator 4 meters height is set outdoors, and the sodium chlorite solution with a concentration of 25 to 30% is injected into the sodium chlorite feeding barrel 1, and the acid liquid feeding barrel 2. Inject a sulfuric acid solution with a concentration of 25-30%. After being heated by the heating rod 3, the temperature of the sulfuric acid is controlled at 45°C, and the temperature of the sodium chlorite is controlled at 75°C. After the filter 4 removes impurities, it is controlled by the glass flowmeter 5 The feed ratio volume ratio of sodium chlorite aqueous solution and concentrated sulfuric acid is 1:1. Under the action of gravity, the sulfuric acid solution and the sodium chlorite solution enter the titanium-aluminum alloy material enteric reactor 6 with a pipe diameter of 20 mm and a pipe length of 5000 mm, and they are repeatedly contacted when flowing through the ...

Embodiment 3

[0023] Such as figure 1As shown, the raw material feeding barrel perpendicular to the chlorine dioxide generator 5 meters height is set outdoors, and the sodium chlorate solution with a concentration of 32 to 40% is injected into the sodium chlorate feeding barrel 1, and the acid solution feeding barrel 2 Inject a nitric acid solution with a concentration of 32-40%. After being heated by the heating rod 3, the temperature of the nitric acid is controlled at 60°C, and the temperature of the sodium chlorite is controlled at 90°C. The feed ratio volume ratio of sodium acid aqueous solution and concentrated sulfuric acid is 1: 1.05. Under the effect of gravity, sulfuric acid solution and sodium chlorite solution enter into the polytetrafluoroethylene intestinal reactor 6 of pipe diameter 50mm, pipe length 6000mm, and contact repeatedly when flowing through intestinal reactor 6, carry out A chemical reaction produces high-concentration, high-purity chlorine dioxide gas. Chlorine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com