Preparation method of mesoporous silicon dioxide hollow sphere

A technology of mesoporous silica and silica spheres, applied in the direction of silica, silica, etc., can solve the problems of insufficient uniform size of mesoporous silica hollow spheres, high price, cumbersome operation process, etc. Prospects for industrial application, mild preparation process conditions, and the effect of orderly pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) In a glass bottle, add 50 mg of silica spheres into 10 mL of water, and ultrasonicate for 30 minutes.

[0026] 2) Add 12.5mg of hexadecyltrimethylammonium bromide to the glass bottle in step 1), stir for 30min, add 212mg of anhydrous sodium carbonate, continue stirring for 1min, then stir and etch at 35℃ for 24h , And finally let it cool down at room temperature.

[0027] 3) Take the white precipitate and wash it twice with water and ethanol, and then dry it naturally to obtain a white powder.

[0028] 4) The target product is obtained after removing the used cationic surfactant from the white powder.

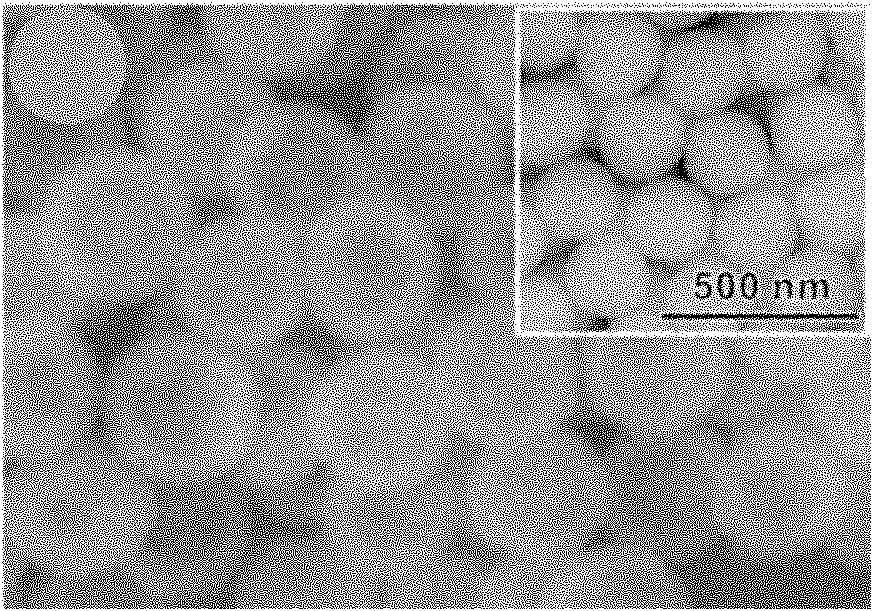

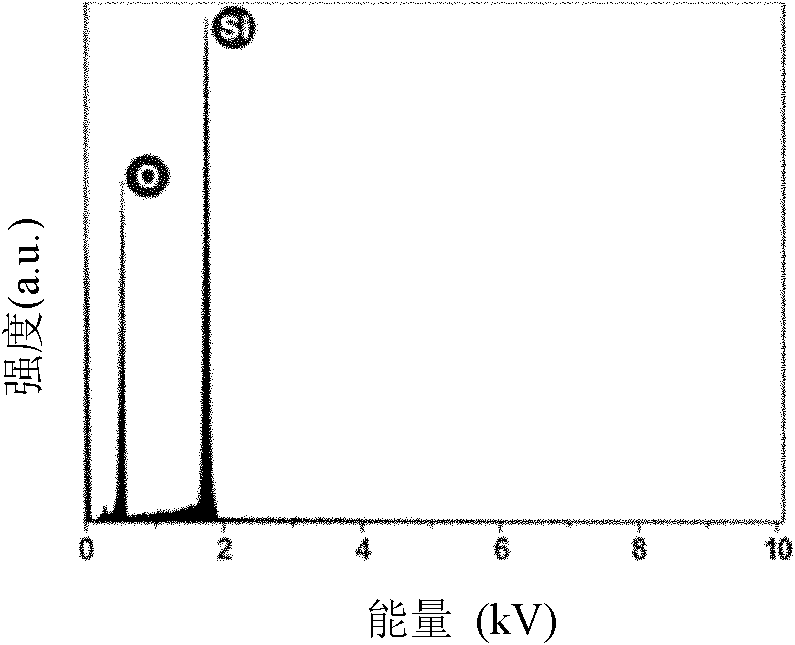

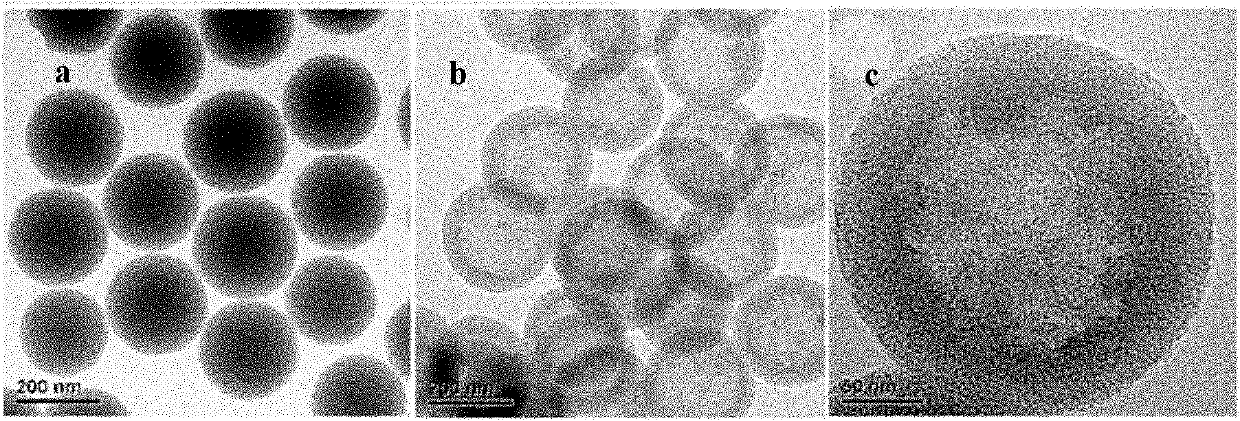

[0029] The product obtained by etching the silica ball with the participation of cationic surfactant has a hollow structure (see figure 1 ); The resulting product composition is Si and O two elements (see figure 2 ), which shows that the composition of the product has not changed compared with the silica balls used; after etching, the product obtained has a hollow structure,...

Embodiment 2

[0031] 1) In a glass bottle, add 50 mg of silica spheres into 10 mL of water, and ultrasonicate for 30 minutes.

[0032] 2) Add 10mg of hexadecyltrimethylammonium chloride to the glass bottle in step 1), stir for 30min, add 212mg of anhydrous sodium carbonate, continue stirring for 1min, and then stir and etch at 35℃ for 24h, Finally, let it stand to cool at room temperature.

[0033] 3) Take the white precipitate and wash it twice with water and ethanol, and then dry it naturally to obtain a white powder.

[0034] 4) The target product is obtained after removing the used cationic surfactant from the white powder.

[0035] The use of cetyltrimethylammonium chloride can also obtain high-quality mesoporous silica hollow spheres (see Image 6 ).

Embodiment 3

[0037] 1) In a glass bottle, add 50 mg of silica spheres into 10 mL of water, and ultrasonicate for 30 minutes.

[0038] 2) Add 10mg of dodecyltrimethylamine bromide to the glass bottle in step 1), stir for 30min, add 212mg of anhydrous sodium carbonate, continue stirring for 1min, and then stir and etch at 35℃ for 24h, Finally, let it stand to cool at room temperature.

[0039] 3) Take the white precipitate and wash it twice with water and ethanol, and then dry it naturally to obtain a white powder.

[0040] 4) The target product is obtained after removing the used cationic surfactant from the white powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com