Novel drought resistant synergistic water fertilizer conditioner and preparation method and application thereof

A conditioner, water and fertilizer technology, applied in the fields of soil and water and fertilizer conditioners, water and fertilizer conditioners, can solve the problems of poor regional adaptability production process and degradability, high price, lack of formula raw materials, etc., to improve the microenvironment of seeds and improve crops. Output, product advanced and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

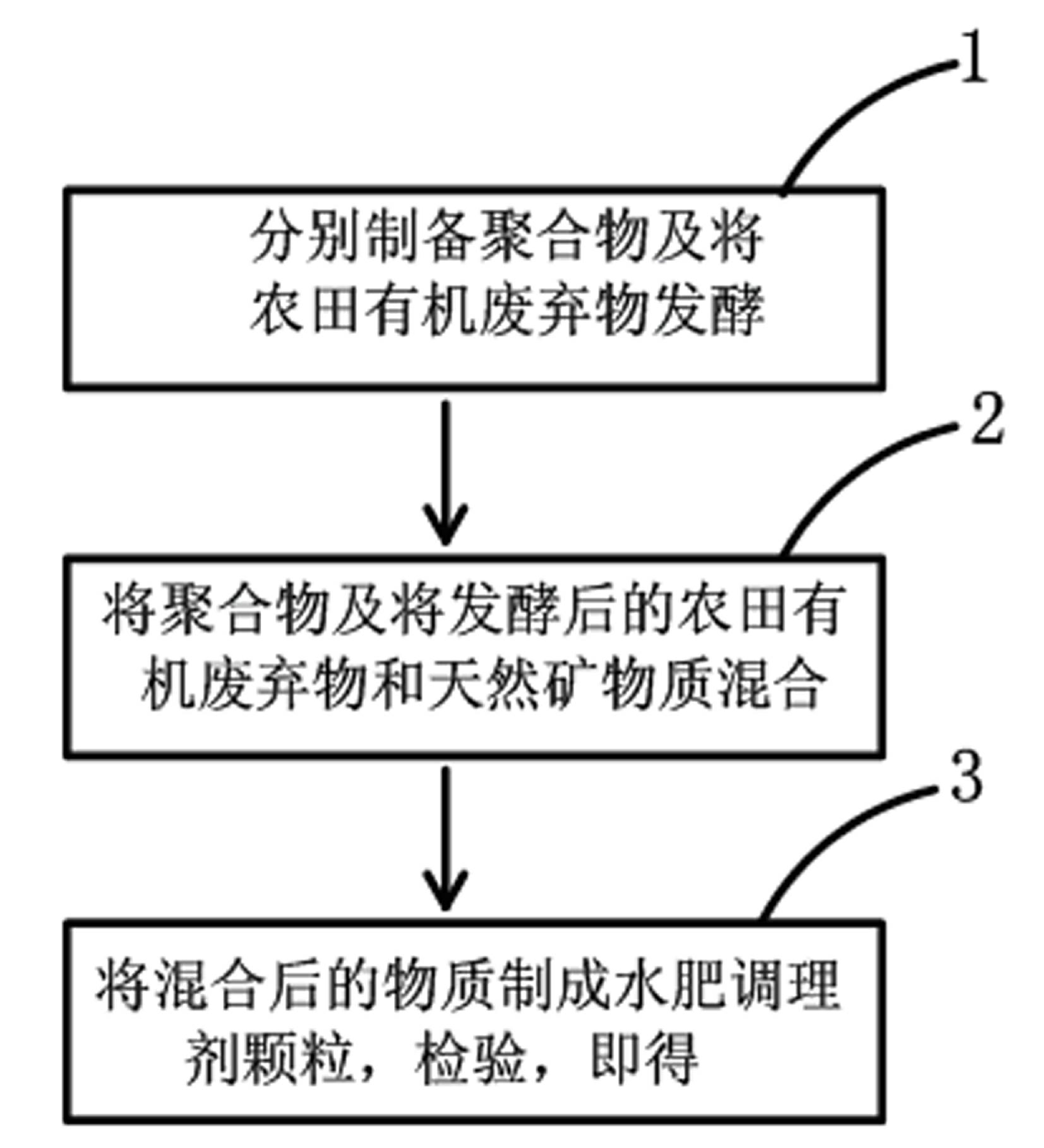

[0031] figure 1 Be the flow chart of the preparation method of novel drought-resistant synergistic water and fertilizer conditioner of the present invention, as figure 1 As shown, the method includes the following steps:

[0032] 1) Preparation of polymers and fermentation of farmland organic waste;

[0033] 2) After the fermented farmland organic waste and natural minerals are pretreated and mixed, mixed with the polymer, and the natural minerals are added for the second time, so that the final ratio is 0-3% of the polymer and 20% of the natural minerals ~30%, farmland organic waste 67%~77%;

[0034] 3) The mixed material is made into water and fertilizer conditioner granules, and then tested to obtain the finished product.

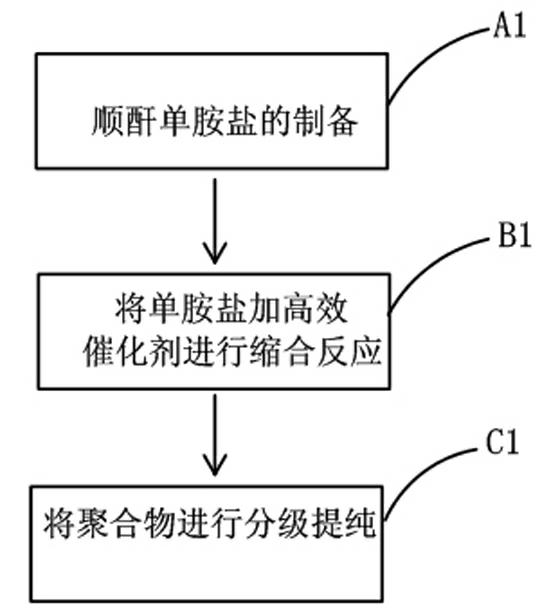

[0035] figure 2 For the flow chart prepared by the polymer in the novel drought-resistant synergistic water and fertilizer conditioner of the present invention, as figure 2 Shown, the preparation of described polymkeric substance comprises the fol...

Embodiment 1

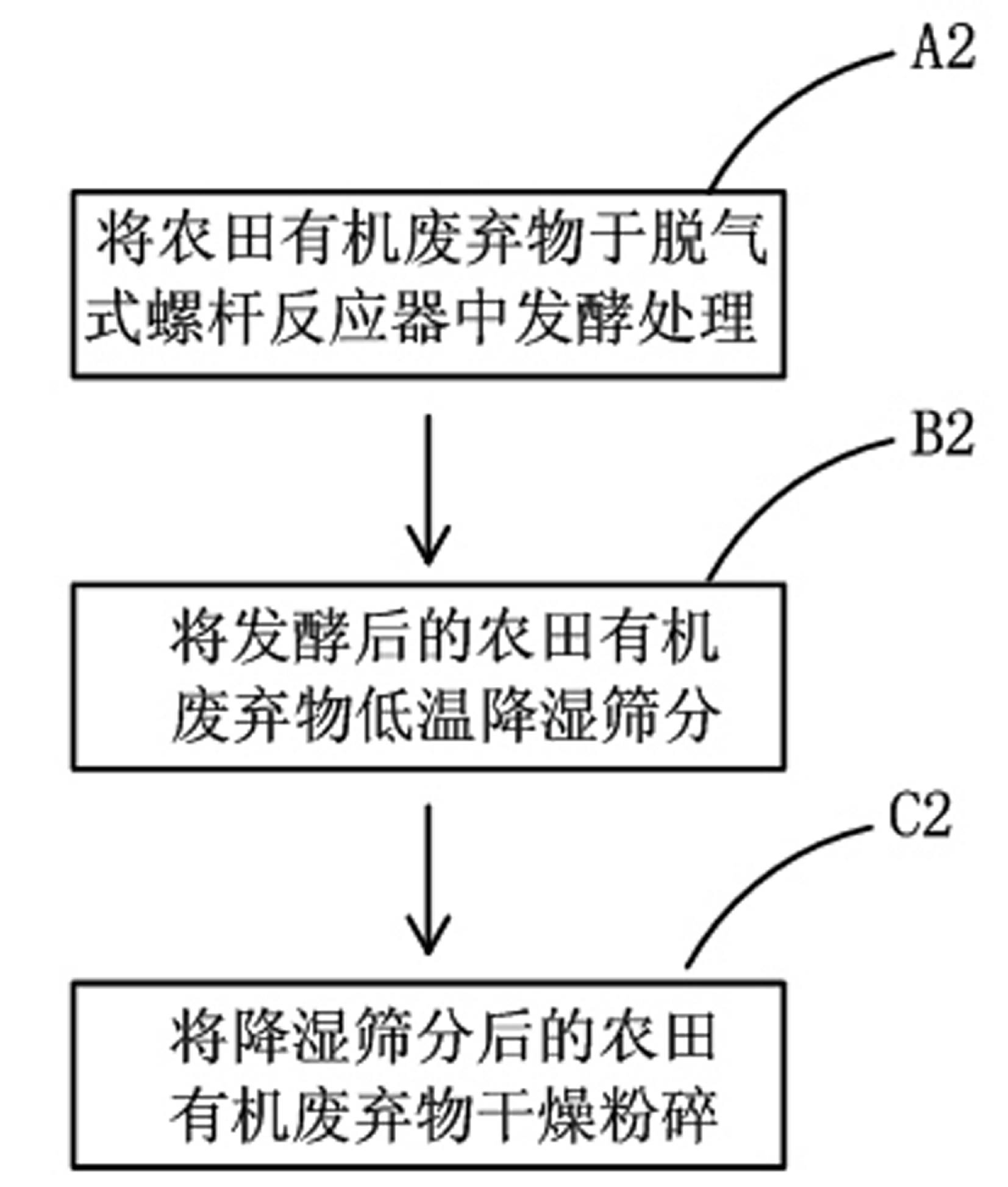

[0044] Prepare polymers and ferment farmland organic wastes respectively; the preparation of the polymers includes: oxidizing benzene and water, pre-cooling and adding water and ammonia to perform ammoniation and maleic anhydride reaction to generate maleic anhydride monoamine salt; Salt plus a high-efficiency catalyst, the high-efficiency catalyst is PAA, polycondensation reaction is carried out at 54 ° C, and the reaction is 6 hours to generate a polymer, and the tail gas is absorbed after the hydrogenation reaction and the polycondensation reaction, and then rinsed for decolorization, Concentration, crystallization, and recycling; the fermentation of farmland organic waste includes adding EM fermentation bacteria to the farmland organic waste, and performing fermentation and harmless treatment in a degassing screw reactor; fermenting the fermented farmland organic waste in Dehumidify and sieve at a low temperature of 25°C; then dry and pulverize to control the fineness at 2-...

Embodiment 2

[0047]Prepare polymers and ferment farmland organic wastes respectively; the preparation of the polymers includes: oxidizing benzene and water, pre-cooling and adding water and ammonia to perform ammoniation and maleic anhydride reaction to generate maleic anhydride monoamine salt; Salt plus high-efficiency catalyst, the high-efficiency catalyst is PAA, conduct polycondensation reaction at 55°C, react for 6.5 hours, generate polymer, and absorb tail gas after ammoniation reaction and polycondensation reaction, then rinse, decolorize, and concentrate , crystallization, and recycling; the fermentation of farmland organic waste includes adding EM fermentation bacteria to the farmland organic waste and carrying out fermentation and harmless treatment in a degassing screw reactor; fermenting the fermented farmland organic waste at low temperature Dehumidify and sieve at 25°C; then dry and pulverize to control the fineness at 2-5 mm.

[0048] The obtained fermented farmland organic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com