Cationic polymerization or cation-free radical mixed polymerization type photopolymerization curing system

A cationic polymerization and mixed polymerization technology, which is applied in the direction of optics, optomechanical equipment, and photoplate-making process of pattern surface, etc., can solve the problems of severe free radical photopolymerization, oxygen inhibition, uneven performance adjustment, poor surface curing, etc. Achieve the effects of improving dry etching resistance, fast polymerization rate, and convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

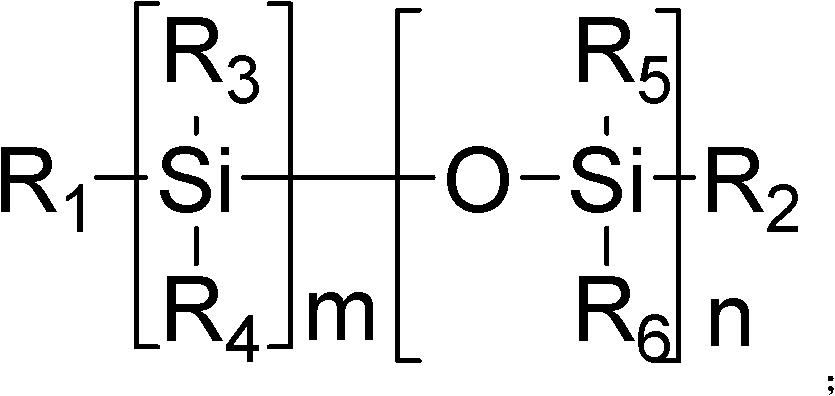

Method used

Image

Examples

Embodiment

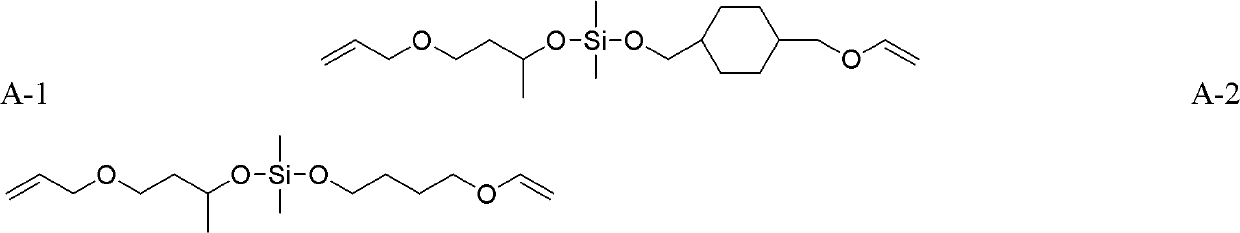

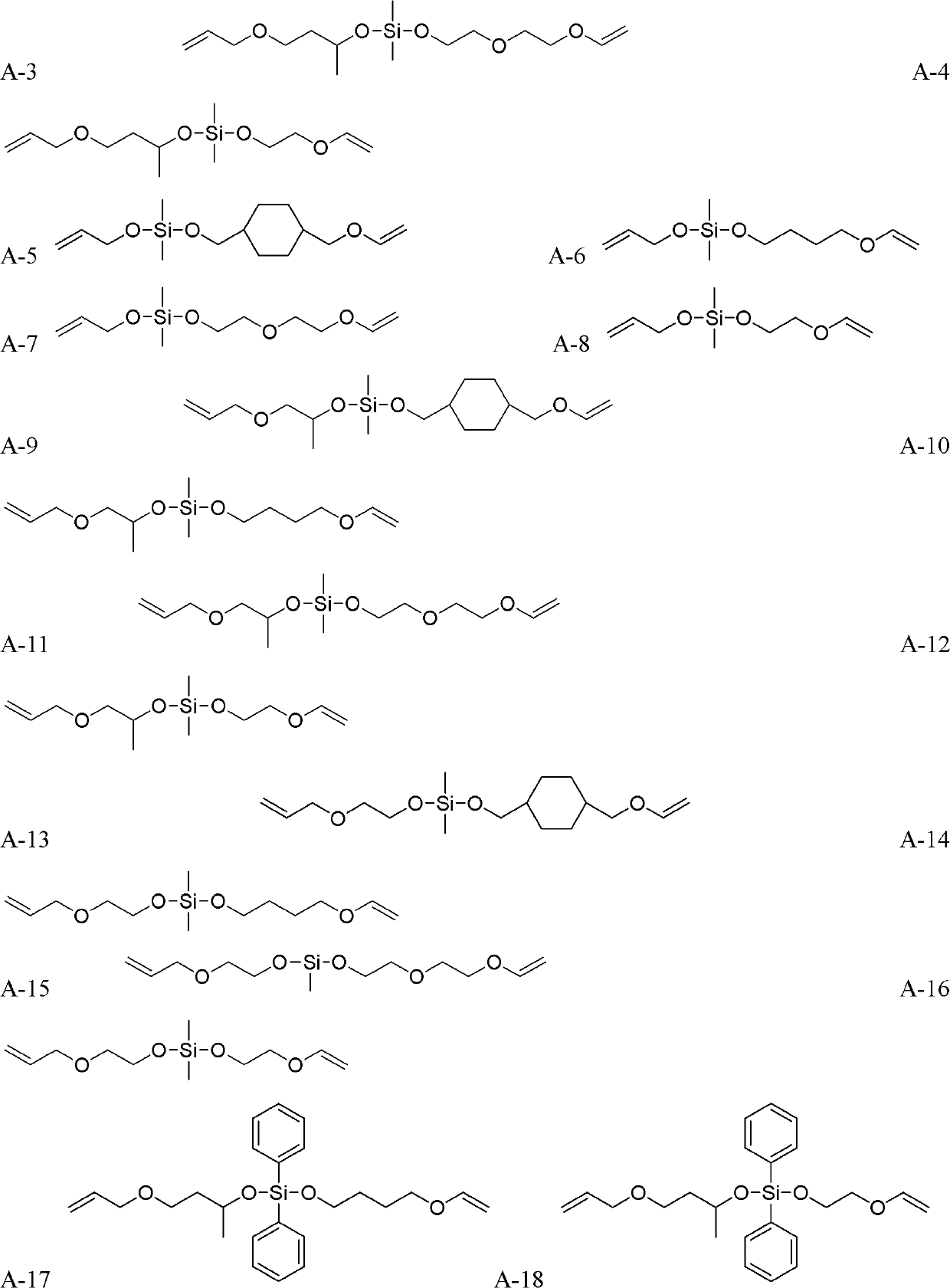

[0041] Dissolve the cationic photopolymerization initiator and the photosensitive monomer whose terminal groups are vinyl ether and allyl ether in the solvent according to the ratio in the following table.

[0042] Coat the curing system on the salt sheet, dry it with hot air to form a film, and put it on the horizontal sample stage of the real-time infrared spectrometer. Directly irradiate the sample with a point light source at room temperature, and adjust the UV light intensity to 30mW / cm 2 , while collecting infrared data. Its aggregation is as follows:

[0043] Polymerization of the curing system initiated by the cationic initiator in table 1

[0044]

[0045] P-1: Mixed triaryl sulfonium fluoroantimonate cationic photoinitiator PAG201;

[0046] P-2: mixed triaryl sulfonium fluoroantimonate cationic photoinitiator PAG202;

[0047] P-3: triaryl sulfonium fluoroantimonate cationic photoinitiator 445;

[0048] P-4: free radical initiator ITX;

[0049] P-5: free radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com