Preparation method and application of molecularly imprinted polymer

A molecular imprinting and polymer technology, applied in organic chemistry and other directions, can solve the problems of large solution concentration, complex preparation process and high cost, and achieve the effect of saving time, expanding the scope of application and simplifying the preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

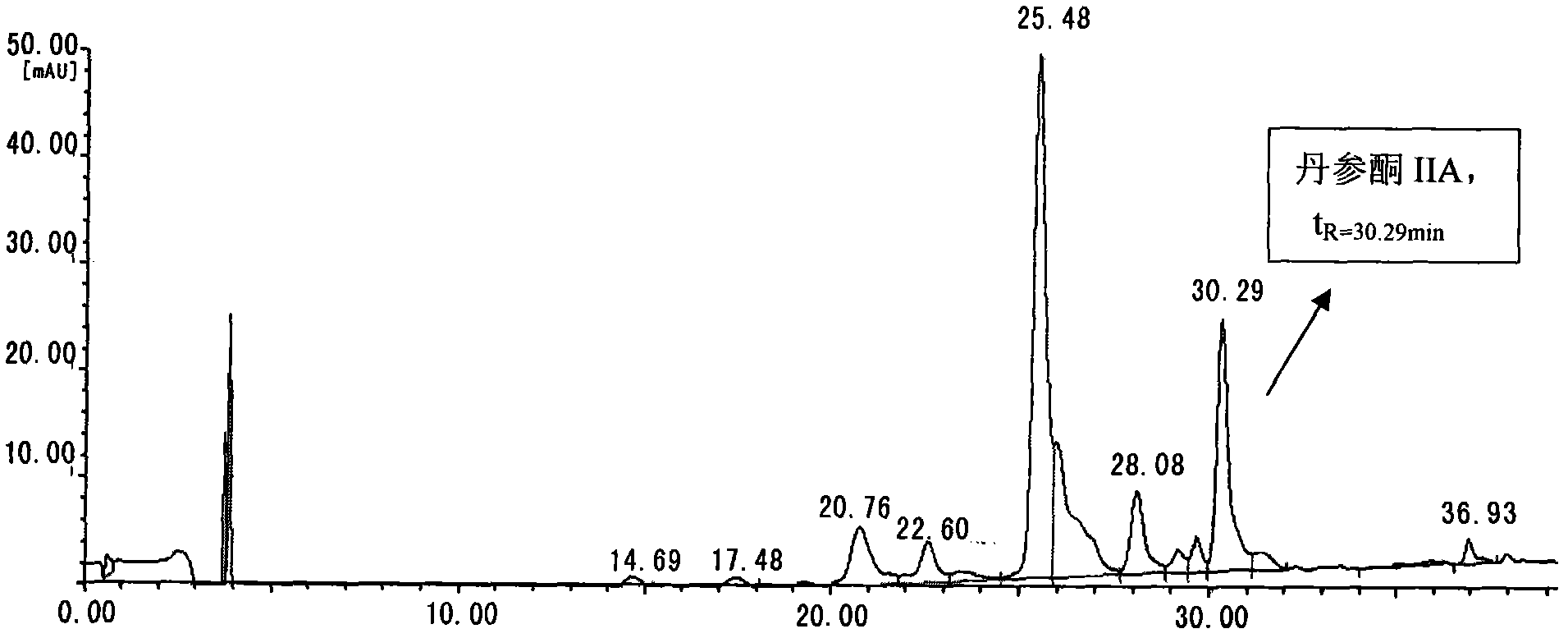

[0028] Weigh 0.5mmol template molecule tanshinone IIA, 2.5mmol functional monomer methacrylic acid (MAA), 10mmol crosslinking agent ethylene glycol dimethacrylate (EDMA), 0.05g initiator azobisisobutyronitrile (AIBN) 1. Put 5mL porogen chloroform into a 50mL ground-mouthed round-bottom flask, and sonicate for 10min until uniformly mixed. After passing nitrogen gas in an ice bath for 10 minutes, seal it; place it in a constant temperature water bath at 60°C for polymerization for 24 hours to obtain a red rod-shaped polymer. The polymer was taken out, soaked in methanol, dried, and sieved. First use 2×100mL methanol to ultrasonically wash, filter with suction, then use 5×100mL1 methanol:acetic acid (V:V=9:1) mixed solution to ultrasonically wash, centrifuge, discard the upper washing solution, and then use 4×100mL methanol to ultrasonically clean Washing, suction filtration, repeated washing until no template molecule is detected under ultraviolet 270nm, and drying in a vacuum ...

Embodiment 2

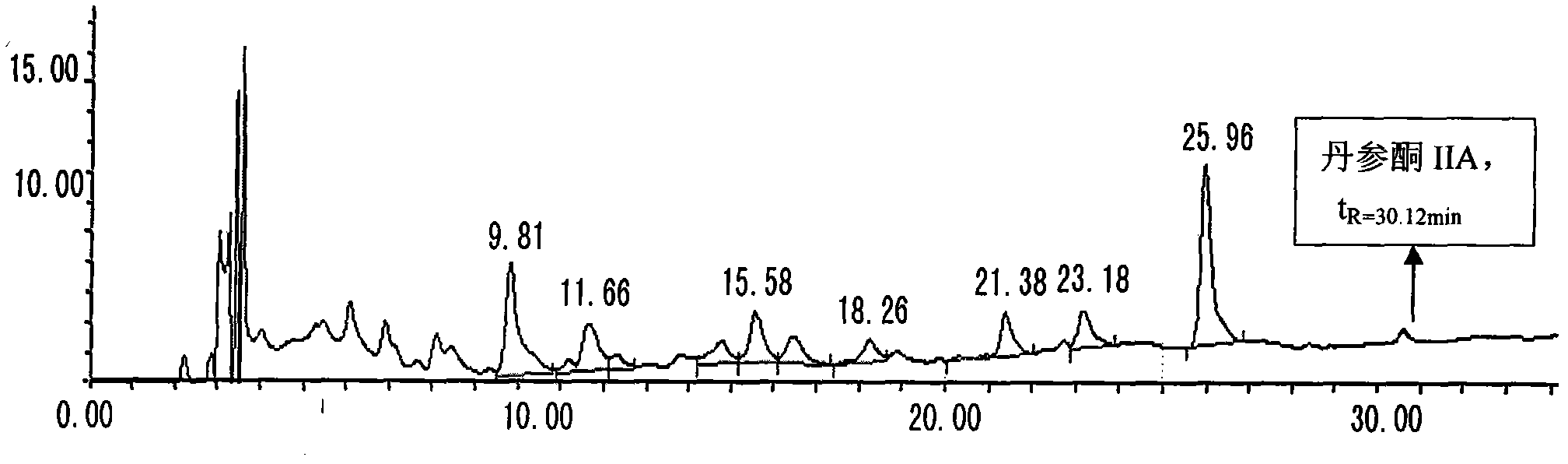

[0030] Weigh 0.5mmol template molecule tanshinone IIA, 2.5mmol functional monomer 2-vinylpyridine (2-VP), 10mmol crosslinking agent trimethylolpropane trimethacrylate (TRIM), 0.05g initiator azobis Isobutyronitrile (AIBN), 5mL porogen dichloromethane, placed in a 50mL ground-mouth round bottom flask, sonicated for 10min until uniformly mixed. After passing nitrogen gas in an ice bath for 10 minutes, seal it; place it in a constant temperature water bath at 65°C for 8 hours to polymerize, and obtain a red rod-shaped polymer. The polymer was taken out, soaked in methanol, dried, and sieved. First use 2×100mL methanol to ultrasonically wash, filter with suction, then use 6×100mL methanol:acetic acid (V:V=9:1) mixed solution to ultrasonically wash, centrifuge, discard the upper washing solution, and then use 5×100mL methanol to ultrasonically clean Washing, suction filtration, and repeated washing until no template molecule is detected under ultraviolet light at 270 nm, and dryin...

Embodiment 3

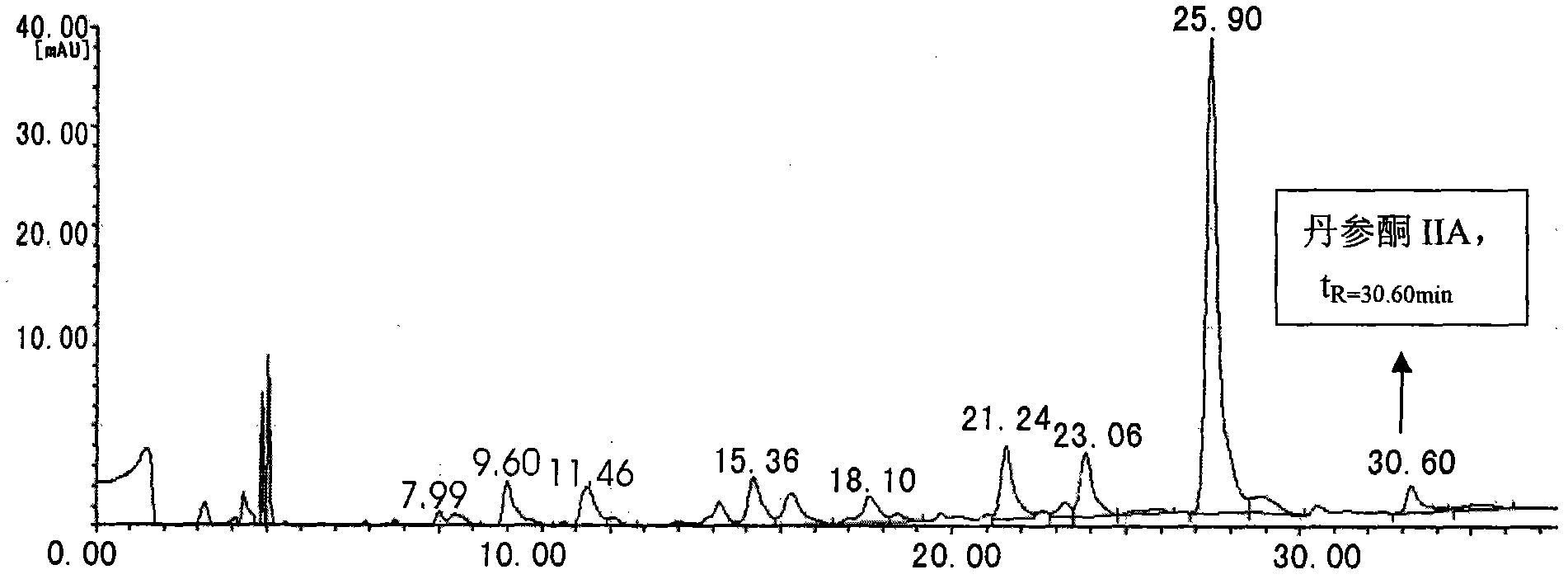

[0032] Weigh 0.5mmol template molecule tanshinone IIA, 2.5mmol functional monomer acrylamide (AM), 10mmol crosslinking agent trimethylolpropane trimethacrylate (TRIM), 0.05g initiator azobisisobutyronitrile (AIBN ), 5mL porogen acetonitrile, placed in a 50mL ground-mouth round-bottom flask, ultrasonicated for 10min until uniformly mixed. After passing nitrogen gas in an ice bath for 10 minutes, seal it; place it in a constant temperature water bath at 60°C for 12 hours to polymerize to obtain a red rod-shaped polymer. The polymer was taken out, soaked in methanol, dried, and sieved. First use 2×100mL methanol to ultrasonically wash, filter with suction, then use 6×100mL methanol:acetic acid (V:V=8.5:1.5) mixed solution to ultrasonically wash, centrifuge, discard the upper washing solution, and then use 5×100mL methanol to ultrasonically clean Washing, suction filtration, repeated washing until no template molecule is detected under ultraviolet 270nm, and drying in a vacuum dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com