Thermal system for preparing heavily-doped silicon single crystal

A technology of silicon single crystal and thermal system, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problems of silicon single crystal becoming polycrystalline, component overcooling, etc., to reduce specific heat capacity and improve reflection effect , The effect of improving the uniformity of axial resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to understand the present invention more clearly, describe the present invention in detail in conjunction with accompanying drawing and embodiment:

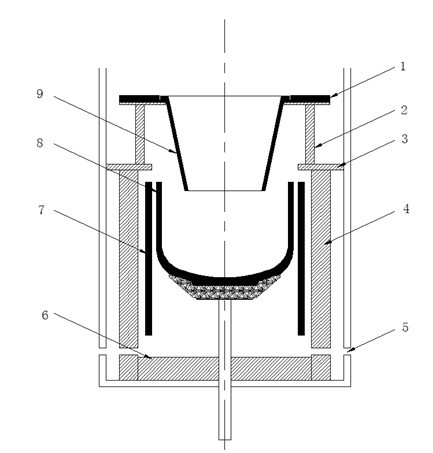

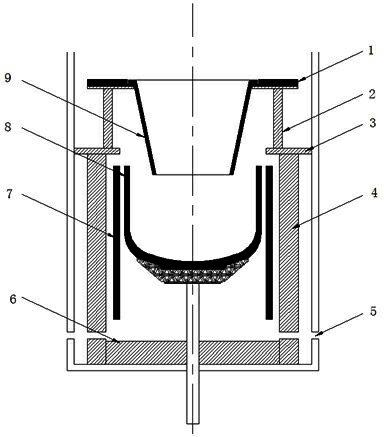

[0011] like figure 1 As shown, the thermal system used for the manufacture of heavily doped silicon single crystal includes a large cover 1, an upper insulation cylinder 2, a support cover 3, a lower insulation cylinder 4, an exhaust pipe 5, a chassis insulation layer 6, a heater 7, and a graphite crucible 8 and guide cylinder 9, the upper insulation cylinder 2, the lower insulation cylinder 4 and the chassis insulation layer 6 adopt a new type of composite heat insulation material; the composite heat insulation material is a multilayer material laminated with customized carbon felt and graphite hard felt, and in The inner surface of the chassis insulation layer 6 is coated with a bright molybdenum metal reflective layer; the material of the support cover 3 is graphite hard felt; the large cover 1 is made of a com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com