Method and equipment for removing phosphorus and metal impurities in ganister sand through vacuum induction melting

A technology for vacuum induction smelting and metal impurities, applied in non-metallic elements, chemical instruments and methods, silicon compounds, etc., can solve the problems of limited disclosure content, no induction melting silicon powder to purify polysilicon, etc., and the method is simple and easy to purify Stable effect and good impurity removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for vacuum induction smelting to remove phosphorus and metal impurities in silicon powder. First, in a high vacuum state, use induction heating to melt silicon powder to remove phosphorus impurities in polysilicon, and then carry out ingot pulling, and use directional solidification technology to melt the silicon powder. removal of metal impurities.

Embodiment 2

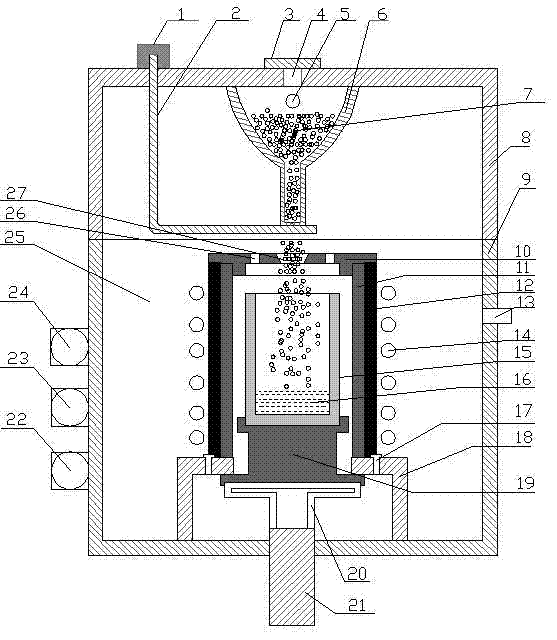

[0029] Vacuum induction smelting equipment for removing phosphorus and metal impurities in silicon powder. The equipment consists of a vacuum furnace cover 8 and a furnace body 9 as a whole. A mechanical pump 22, a Roots pump 23 and a diffusion pump 24 are installed outside the furnace. The inside of the body is a vacuum chamber 25; there is a feeding port 4 above the furnace cover 8, and a gasket 3 is added above the feeding port 4 for sealing. With an external drive type baffle, the external drive type baffle is an L-shaped baffle, one end of the baffle is rotated and connected to the controller, the controller is installed outside the furnace, the discharge port is aligned with the melting crucible, and the melting crucible is placed in the insulation sleeve , the insulation cover 12 is positioned on the bracket 18 at the lower part of the furnace body, and is fixed by the positioning bolt 17. The graphite sleeve 11 is set in the insulation cover 12, and the graphite sleeve ...

Embodiment 3

[0031]Adopt the equipment described in embodiment 2 to remove phosphorus and metal impurities in silicon powder for production. The first step is to prepare materials: put a small amount of high-purity polysilicon material into the quartz crucible 15 as the base material for smelting; rotate the controller 1. Make the baffle 2 block the discharge hole of the hopper 6, and put the polysilicon powder 7 with a phosphorus content of 0.003% and a metal impurity content of 0.01% into the hopper 6, and the loading position shall not exceed the hopper vent hole 5 on the hopper 6 , and then cover the sealing cover 3;

[0032] The second step pretreatment: close the furnace cover 8, then carry out the vacuuming process, first turn on the mechanical pump 22, the Roots pump 23 to carry out the vacuum pre-extraction, when the vacuum degree of the vacuum chamber 25 reaches 5Pa, open the diffusion pump 24 to vacuum the vacuum chamber 25 internal vacuum pumped to 10 -3 Pa; Pass cooling water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com