Method for treating ship ballast water by injecting oxygen active particles in transmission pipe

A technology of ship ballast water and oxygen activity, which is applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of safety, high energy consumption, poor penetrability, leakage, etc., and achieve large production capacity and equipment Simple, concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Specific embodiments of the present invention will be described in detail below in conjunction with the technical solution and the drawings.

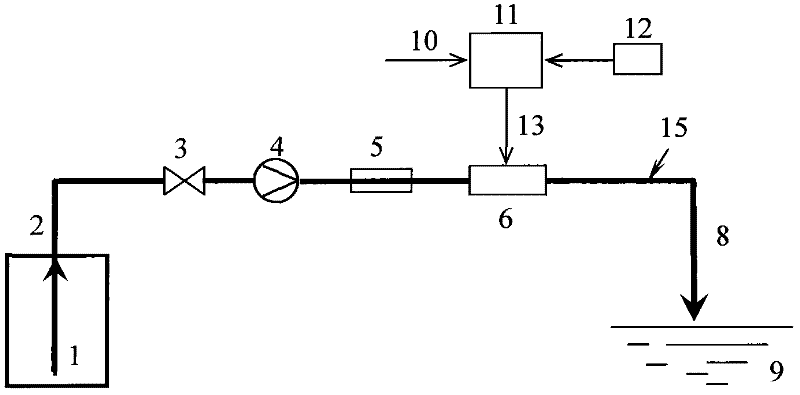

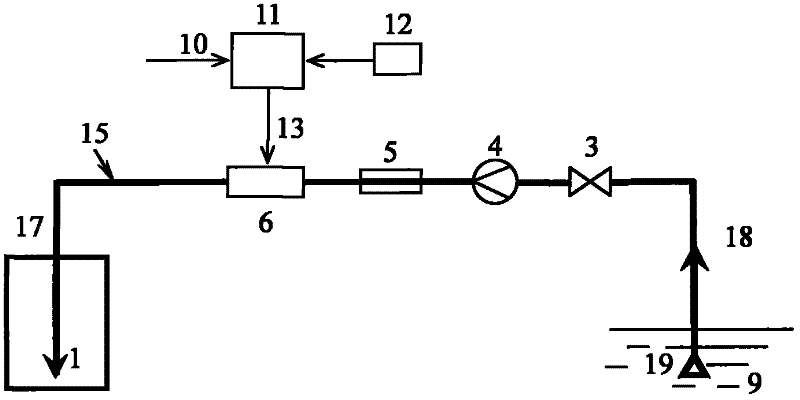

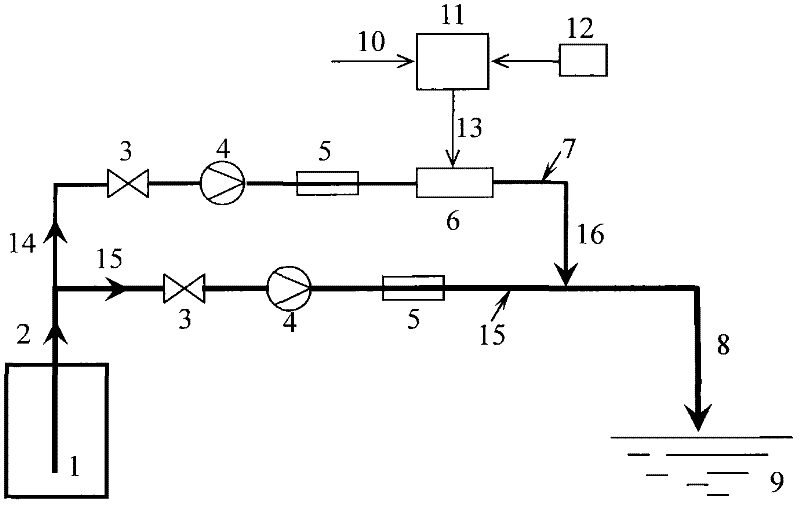

[0044] The method of the present invention for injecting oxygen-active particles into the ballast water treatment of ships in a transportation pipeline can be implemented in the following four ways: (1) In the process of ballast water discharge, oxygen-active particles are injected into the ballast water for transportation. The main pipeline generates hydroxyl radicals for ship ballast water treatment, as attached figure 1 As shown; (2) In the process of loading ballast water, oxygen-active particles are injected into the main ballast water transportation pipeline to generate hydroxyl radicals for ship ballast water treatment, as attached figure 2 As shown; (3) In the process of ballast water discharge, oxygen-active particles are injected into the branch pipeline that takes 1 / 4~1 / 20 ballast water from the main pipeline of ballast w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com