Device and method for manufacturing optical fiber prefabrication rod mandrel

A technology of optical fiber prefabricated rods and core rods, which is applied to the device for manufacturing optical fiber prefabricated rods and core rods, and in the field of manufacturing optical fiber prefabricated rods. Fluctuation of growth rate and density, reduction of uneven temperature distribution, uniform growth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

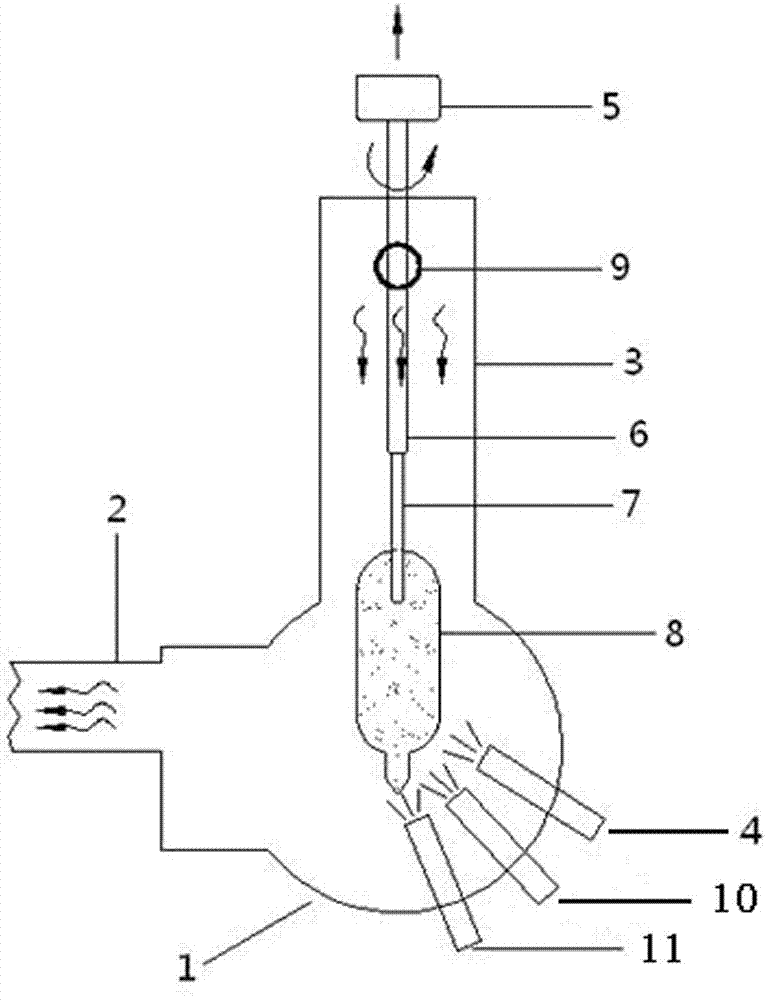

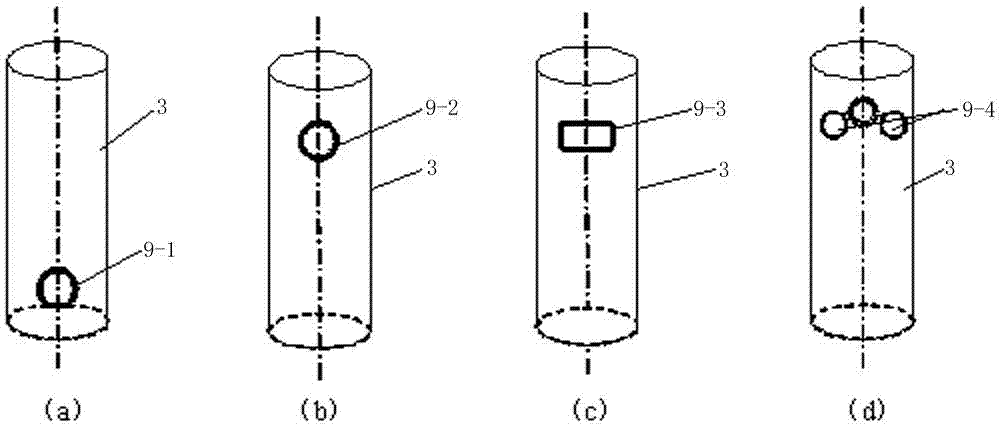

Embodiment 1

[0043] Embodiment one: figure 2 (a) is the first setting method of the supplementary air outlet, and a circular supplementary air outlet with a diameter of 100mm is installed at a position 200mm away from the lower end of the upper cavity. A quartz target rod 7 is installed on the boom 6, and the target rod 7 is lowered to a suitable position in the spherical reaction chamber 1 to be opposite to the torch. Open the exhaust device and start exhausting, start to pass into hydrogen and oxygen in the blowtorch simultaneously and ignite to produce hydrogen-oxygen flame, then pass into SiCl to the 3rd blowtorch 11 4 and GeCl 4 Gas raw material, which undergoes hydrolysis reaction in an oxyhydrogen flame to form SiO 2 、GeO 2 The powder is deposited on the lower end of the target rod to form the core layer of the prefabricated mandrel, and at the same time, SiCl is injected into the first torch 4 and the second torch 10 respectively. 4 Gas feedstock, resulting in SiO 2 The powde...

Embodiment 2

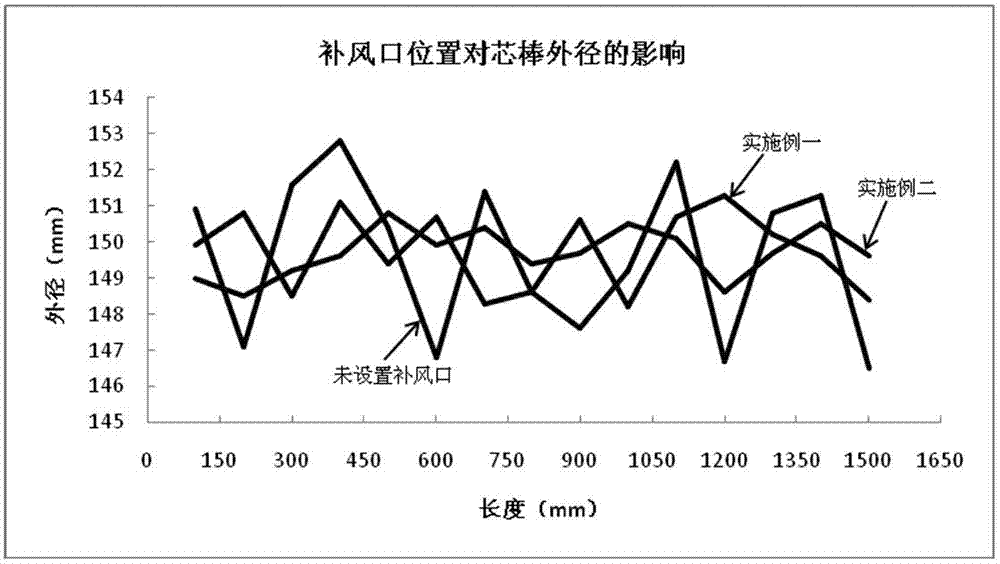

[0044] Embodiment two: figure 2 (b) For the second setting method of the air supply port, a circular air supply port with a diameter of 100mm is set at a position 200mm from the upper end of the upper cavity. After the air supply port is set at the upper position, the internal pressure and air flow of the entire space including the upper cavity can be stabilized. At the end of the deposition, the outer diameter and core-to-cover ratio of the preform are measured. From image 3 It can be seen from the figure that when the air supply port is set at this position, the fluctuation range of the outer diameter of the preform along the length direction is ±1.5mm, and the fluctuation is small. From Figure 5 It can be seen that the core-to-package ratio of the preform varies along the length direction, and the core-to-package ratio fluctuates from 3.62 to 3.66. same image 3 and Figure 5 Compared with the case where no supplementary air port is set in the case, the quality of ...

Embodiment 3

[0045] Embodiment three: figure 2 (c) For the third setting method of the air supply port, a rectangular air supply port with a length of 100mm and a width of 80mm is set at a position 200mm away from the upper end of the upper cavity. At the end of the deposition, the outer diameter and core-to-cover ratio of the preform are measured. From Figure 4 It can be seen from the figure that when the air supply port of this shape is set at this position, the fluctuation range of the outer diameter of the preform along the length direction is ±2mm. From Figure 6 It can be seen that the core-to-package ratio of the preform varies along the length direction, and the core-to-package ratio fluctuates from 3.55 to 3.72.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com