Preparation method of CaCu3Ti4O12 ceramic

A technology of ceramics and cuo, applied in the field of preparation of CaCu3Ti4O12 ceramics, can solve the problems of secondary growth of crystal grains, ceramic properties, influence of ceramic structure, densification, deterioration, etc., to reduce high temperature and low frequency dissipation, uniform particle size, structure dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment l

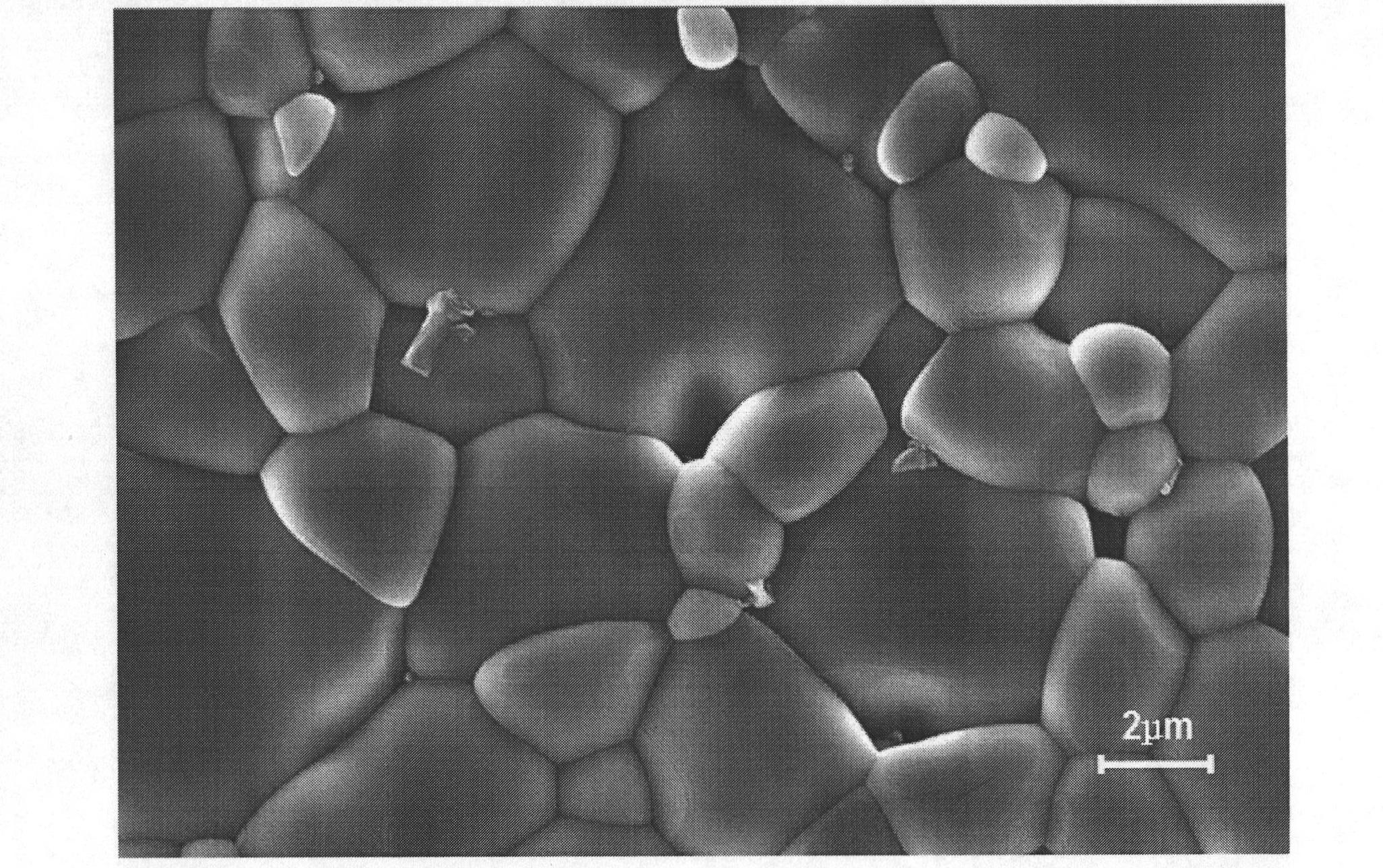

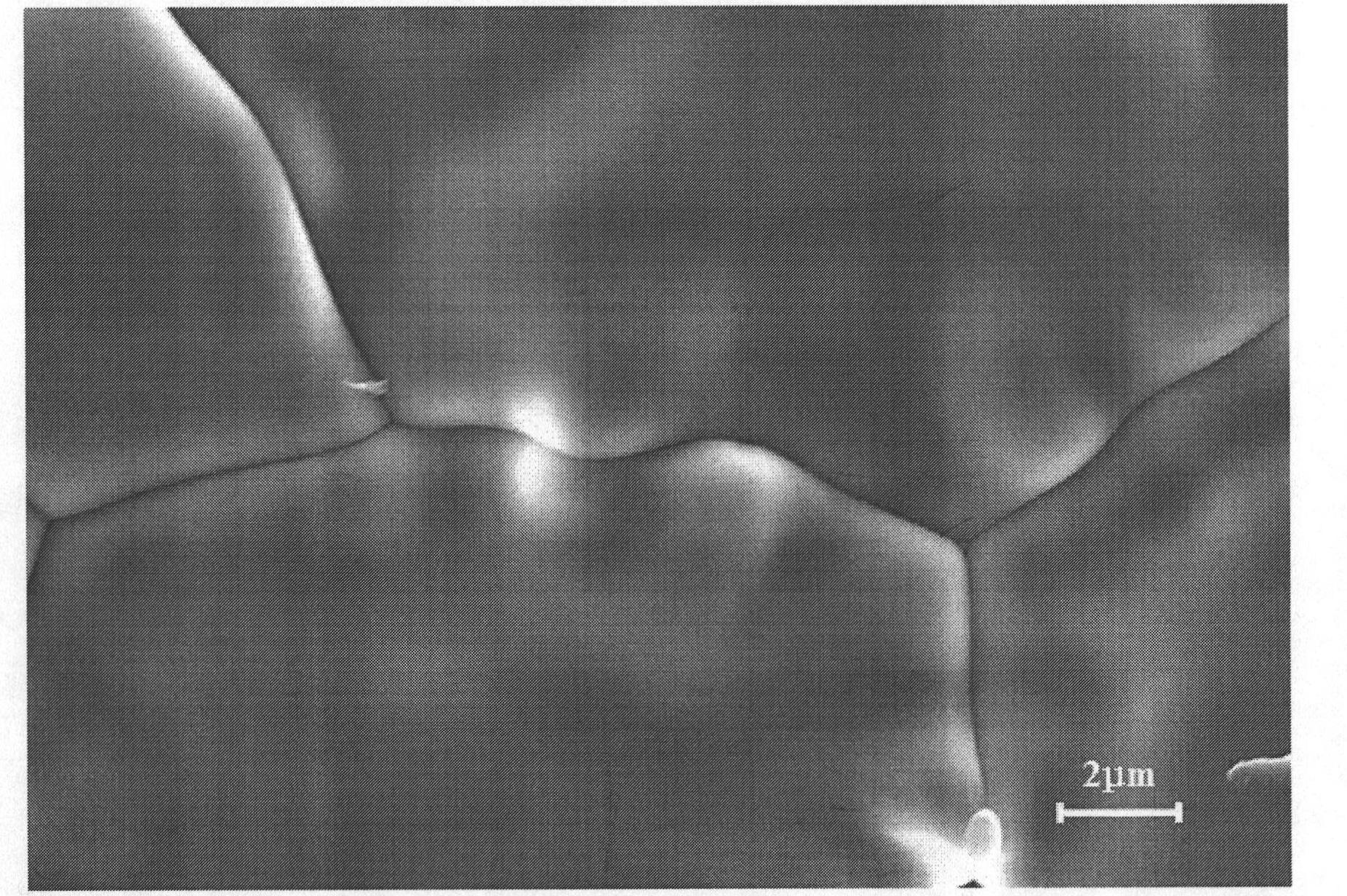

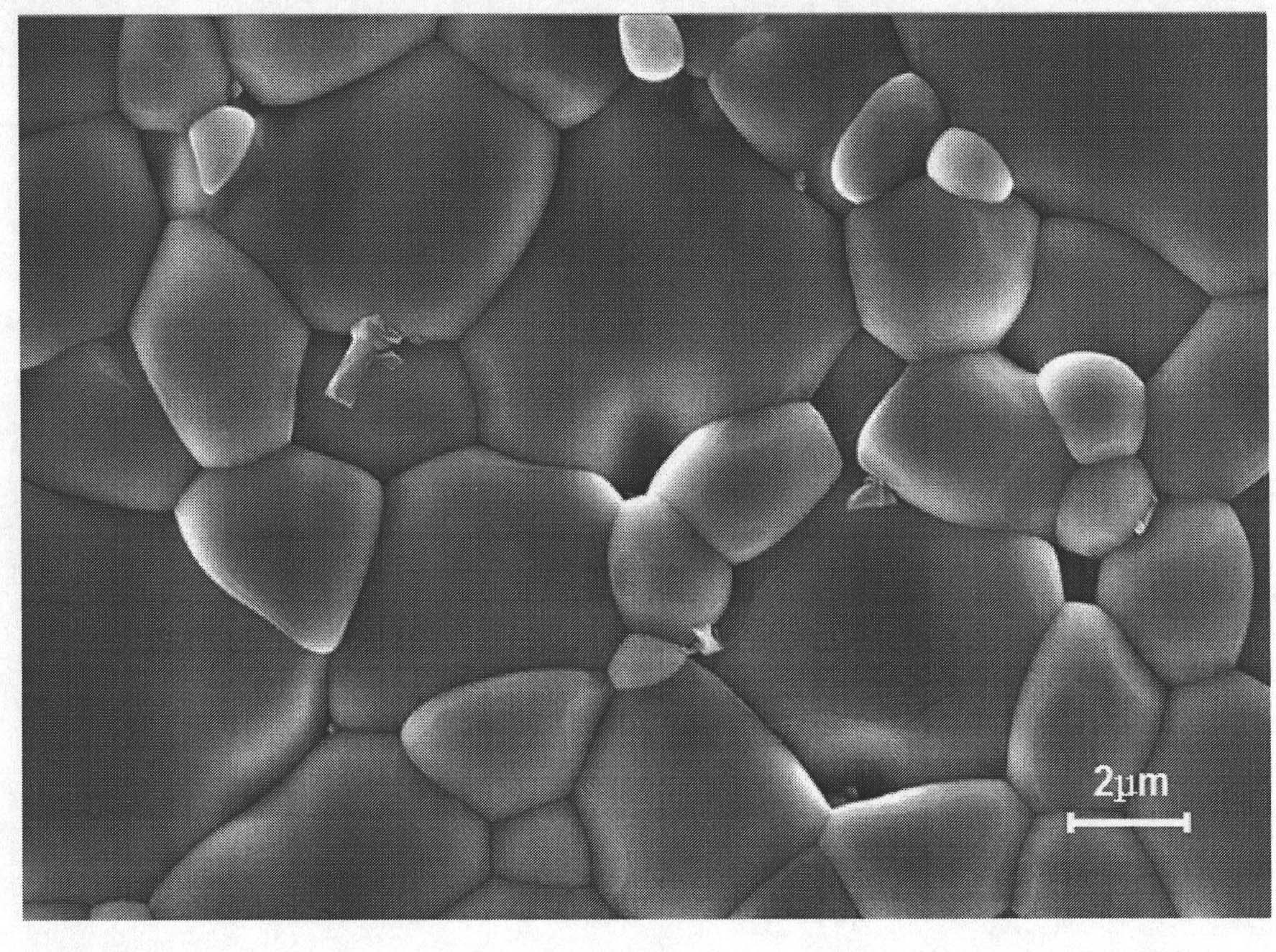

[0019] Embodiment 1: with high-purity 3.0414g CaCO 3 (>99%), 7.2514g CuO (>99%), 9.7074gTiO 2 (>99%) powder as the raw material, according to the CCTO stoichiometric ratio, mix 20g of material, ball mill in distilled water medium for 12h; dry and sieve the powder and pre-calcine at 960°C for 2h. Add 15.4ml ethanol, 0.25ml n-butanol and 0.36ml trioleic acid glyceride to the powder after pre-burning, then put into the nylon ball mill jar, and use ZrO 2 The ball is used as the grinding medium, and it is put into a planetary ball mill with a speed of 400rad / min for wet grinding for 23 hours; 0.9592g of polyethylene glycol, 1.0ml of dioctyl phthalate, and 1.3174g of polyethylene are added to the wet material that has been ground for 23 hours. Alcohol butyral and 0.24ml cyclohexane, and then ball milled for 20h at a speed of 350rad / min; pour the slurry into a small beaker and take out all the ZrO 2 Then pour the slurry into a casting machine with a clean and smooth glass plate, so...

Embodiment 2

[0020] Embodiment 2: with high-purity 3.344g CaCO 3 (>99%), 7.9765g CuO (>99%), 10.6788gTiO 2 (>99%) powder as the raw material, according to the CCTO stoichiometric ratio of 22g material, ball milled in distilled water medium for 12h; the dried and sieved powder was pre-fired at 960°C for 2h. Add 15.48ml ethanol, 0.3ml n-butanol and 0.4ml triolein to the powder after pre-burning, then put it into a nylon ball mill jar, and use ZrO 2 The ball is used as the grinding medium, and it is put into a planetary ball mill with a speed of 400rad / min for wet grinding for 20 hours; 0.960g of polyethylene glycol, 0.997ml of dioctyl phthalate, and 1.321g of polyethylene are added to the wet material that has been ground for 20 hours. Alcohol butyral and 0.28ml cyclohexane, and then ball milled for 20h at a speed of 400rad / min; pour the slurry into a small beaker and take out all the ZrO 2Then pour the slurry into a casting machine with a clean and smooth glass plate, so that it moves at ...

Embodiment 3

[0021] Embodiment 3: with high-purity 3.7561g CaCO 3 (>99%), 8.9555g CuO (>99%), 11.9886gTiO 2 (>99%) powder as the raw material, according to the CCTO stoichiometric ratio of 24.7g material, ball milled in distilled water medium for 10h; the dried and sieved powder was pre-fired at 960°C for 2h. ; Add 15.5ml ethanol, 0.4ml n-butanol and 0.4ml trioleic acid glyceride to the powder after pre-burning, then put into the nylon ball mill jar, and use ZrO 2 The ball is used as the grinding medium, put it into a planetary ball mill with a rotation speed of 400rad / min for 24 hours; add 0.9663g of polyethylene glycol, 0.99ml of dioctyl phthalate, and 1.34g of polyethylene to the wet material that has been ground for 24 hours Alcohol butyral and 0.3ml cyclohexane, and then ball milled for 20h at a speed of 400rad / min; pour the slurry into a small beaker and take out all the ZrO 2 Then pour the slurry into a casting machine with a clean and smooth glass plate, so that it moves at a con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com