Dihydromyrcenol fixed bed hydration continuous production method

A technology of dihydromyrcenol and dihydromyrcene, which is applied in the field of continuous production of dihydromyrcenol fixed bed hydration, to achieve the effects of guaranteed reaction efficiency, low equipment investment, and reduced breakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

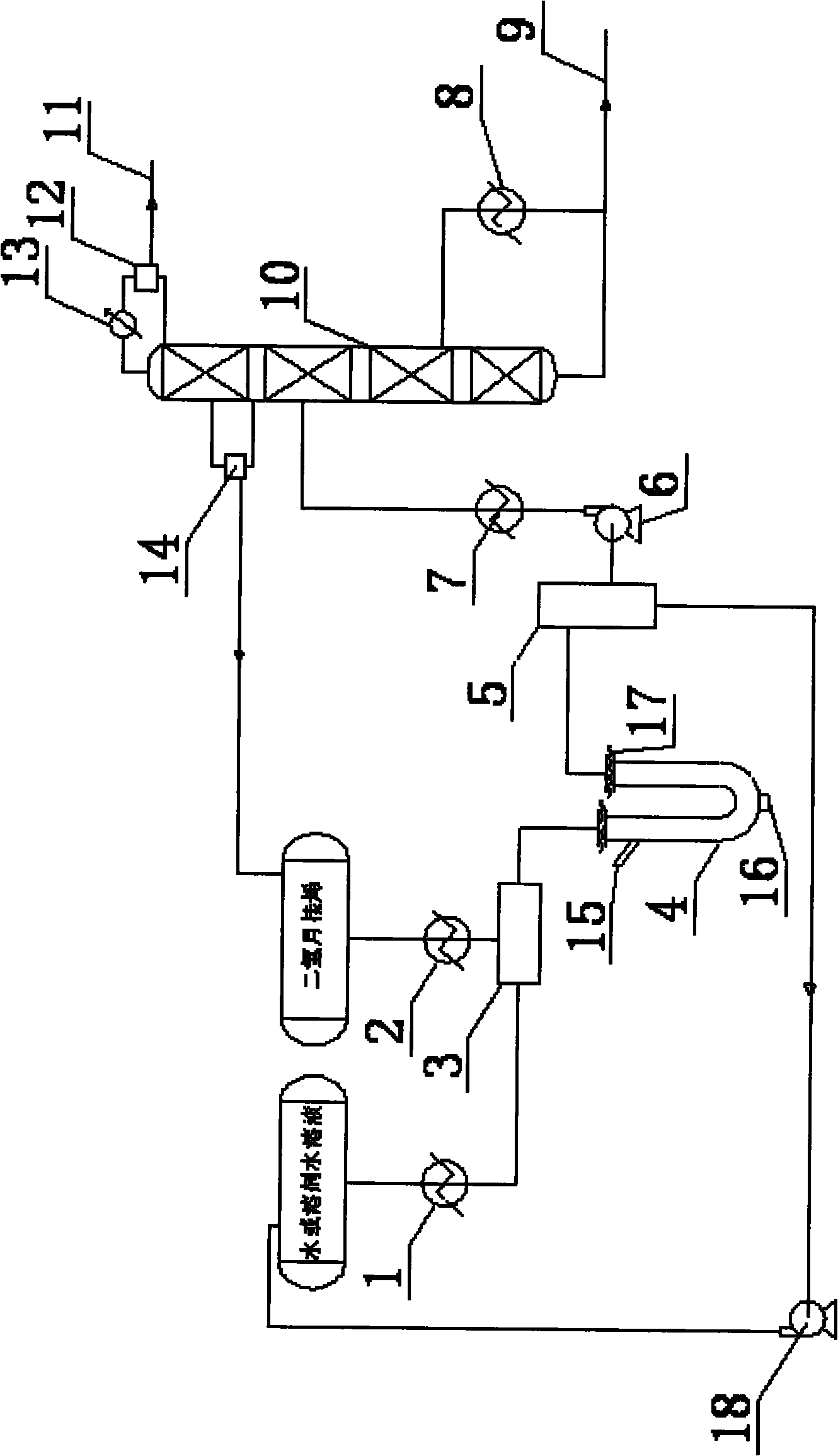

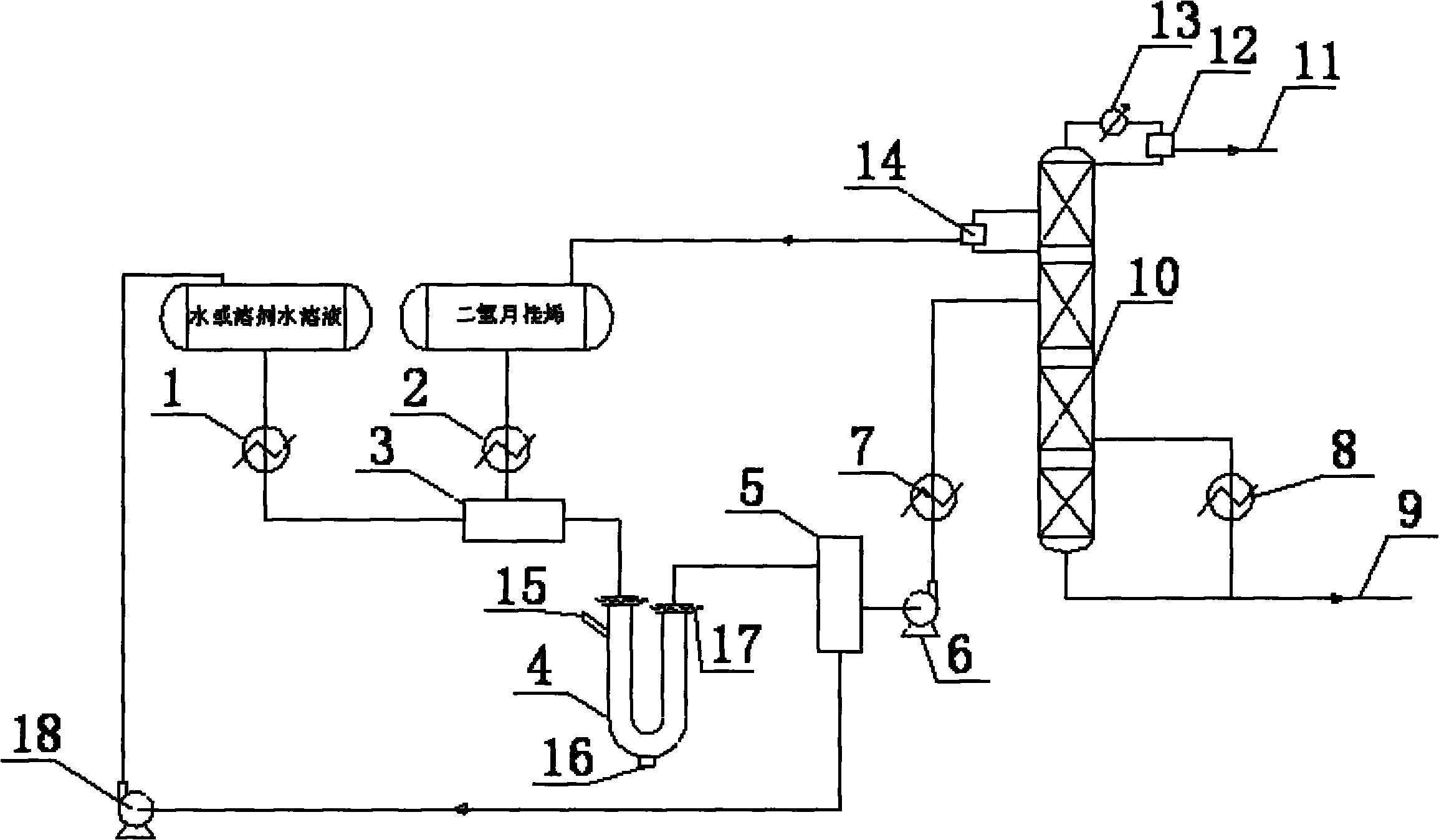

Method used

Image

Examples

Embodiment 1

[0029] Fill the solid acid catalyst in the tubular reactor 4 in advance, use the ion exchange resin as the solid acid catalyst, the ion exchange resin in this place is the conventional ion exchange resin on the market (such as: macroporous strongly acidic styrene series cation exchange resin, etc.). Dihydromyrcene, solvent (dioxane): water, according to the mass ratio of 1:1:1, are preheated by feed preheaters 1 and 2 respectively to reach a reaction temperature of 80°C, and then pass through a pressurized injection device 3 After homogenization, it enters the tubular reactor 4 for reaction. After the liquid is filled with the tubular reactor 4, it enters the oil-water separator 5 through the catalyst filter 17 for oil-water layering. The lower water layer is returned to the solvent aqueous solution tank through the centrifugal pump 18, and the oil layer Enter the rectification tower 10 through the centrifugal pump 6 and the feed preheater 7. After being separated by the recti...

Embodiment 2

[0032] Dihydromyrcene, solvent acetone: water, according to the ratio of mass ratio 1: 0.5: 0.5, reach 70 ℃ of reaction temperature through the preheating of feed preheater 1,2 respectively, other conditions are with embodiment 1, the second step of this process The conversion rate of hydromyrcene is 91.5%, and the selectivity is over 92%.

Embodiment 3

[0034] Similar to the operation process of Example 1, pure water replaces the solvent aqueous solution to participate in the reaction, and is preheated by feed preheaters 1 and 2 respectively to reach a reaction temperature of 75°C. The conversion rate of dihydromyrcene in this process is more than 85%. Sex is above 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com