High-capacity energy storage capacitor

A capacitor and large-capacity technology, applied in the direction of fixed capacitor dielectric, fixed capacitor parts, etc., to achieve the effect of increasing capacity, environmental coordination, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Preparation of sample raw materials: select pure barium carbonate (BaCO 3 ), calcium carbonate (CaCO 3 ), Zirconia (Zr 2 o 3 ) and spectroscopically pure titanium oxide (TiO 2 ) as raw materials; the raw materials are all products of Sinopharm Chemical Reagent Company, and the raw materials are baked at 110° C. in an oven for 8 hours before weighing.

[0021] The molar ratio (mol) of the oxide raw materials according to the stoichiometric ratio is: BaCO 3 : CaCO 3 : Zr 2 O:TiO 2 = 0.9:0.1:0.03:0.94(BCZT-1) and 0.9:0.1:0.105:0.79(BCZT-2), will weigh barium carbonate (BaCo 3 ), calcium carbonate (CaCo 3 ), Zirconia (Zr 2 o 3 ) and titanium oxide (TiO 2) was ball milled with absolute ethanol as the medium, dried after ball milling for 24 hours, put into an alumina crucible, pressed lightly, placed in the air, and pre-synthesized at 800°C for 8 hours. Perform ball milling and drying treatment. The ball milling time is 24 hours. After ball milling, put them into...

Embodiment 2

[0025] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0026] The organic material is polypropylene, and the Ba 0.9 Ca 0.1 Zr 0.06 Ti 0.94 o 3 The weight percentage with the first dielectric film is 70%, the Ba 0.9 Ca 0.1 Zr 0.21 Ti 0.79 o 3 The weight percentage of the second dielectric film is 70%, and the weight ratio of the first dielectric film to the second dielectric film is 1.5:1.

Embodiment 3

[0028] The technical solution of this embodiment is basically the same as that of Embodiment 1, the difference is that:

[0029] The organic material is polypropylamine, and the Ba 0.9 Ca 0.1 Zr 0.06 Ti 0.94 o 3 The weight percentage with the first dielectric film is 65%, the Ba 0.9 Ca 0.1 Zr 0.21 Ti 0.79 o 3 The weight percentage of the second dielectric film is 64%, and the weight ratio of the first dielectric film to the second dielectric film is 1:1.

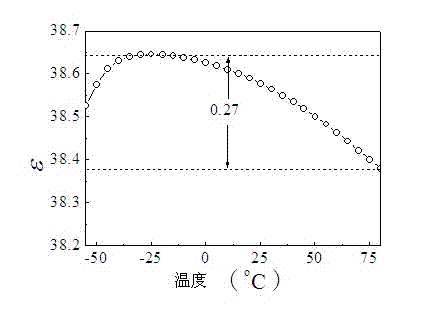

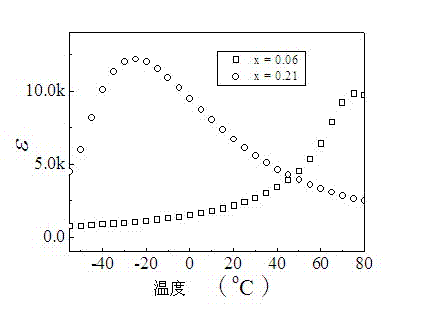

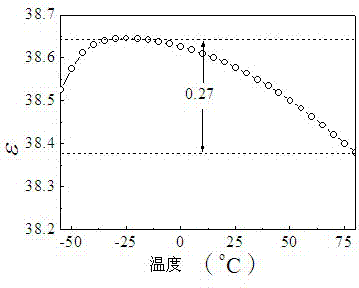

[0030] From figure 1 It can be seen in the figure: the variable temperature dielectric properties of BCZT-1 and BCZT-2 samples, it can be seen that the dielectric constant of the samples is effectively improved and the phase transition peak of the samples is broadened by the method of doping.

[0031] From figure 2 It can be seen in the figure: 65% BCZT-1 and 64% BCZT-2 are glued with organic materials with a dielectric constant of 3, and combined in parallel to obtain the dielectric constant change curve of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com