Method for preparing multilayer titanium dioxide mesoporous film electrode for solar batteries

A technology for solar cells and titanium dioxide, applied in the field of solar cells, can solve problems such as difficulty in film preparation, and achieve the effects of good repeatability, simple production process and shortened distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

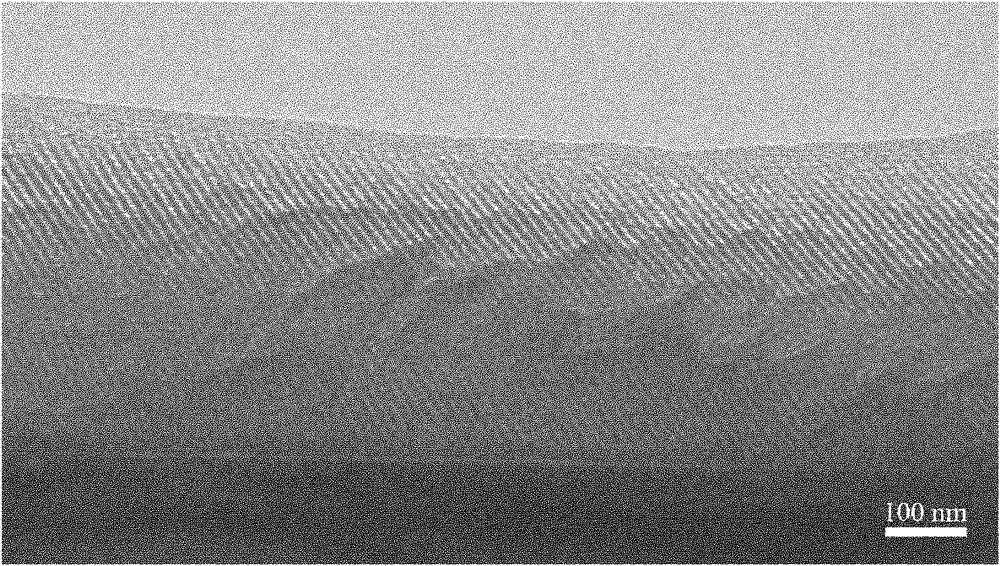

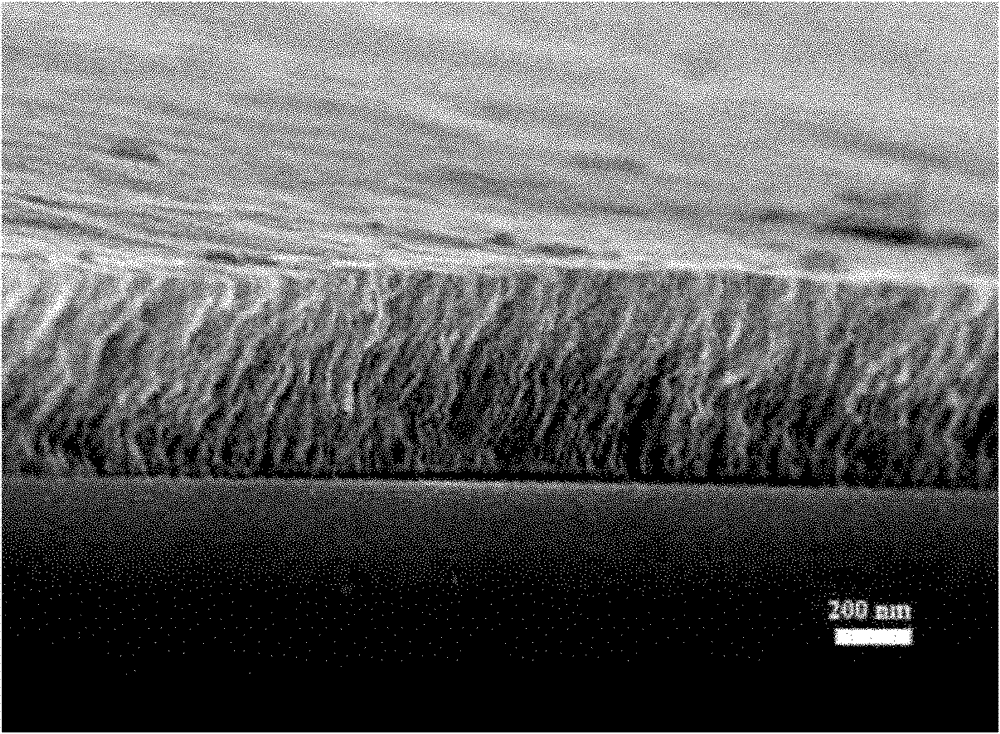

Image

Examples

Embodiment 1

[0024] This embodiment 1 is implemented under the following conditions of implementation and technical requirements:

[0025] (1) Add 1.6g of concentrated hydrochloric acid dropwise to 2.1g of tetraethyl titanate, stir for 5 minutes and mix with 0.65g of surfactant P123 in n-butanol, stir at 20°C for 3 hours to form a uniform and transparent sol- Gel Precursor.

[0026] (2) Drop the prepared sol-gel precursor solution on a clean FTO conductive glass plate, add a moving airflow that forms an angle of 45 degrees with the FTO conductive glass plane, adjust the wind speed to be 20 m / s, in the airflow Under the action of , the sol solution forms a layer of titanium dioxide film;

[0027] (3) Put the prepared titanium dioxide film into a constant temperature and humidity box at 20°C and 80% relative humidity, age it for 24 hours, and then put it into a muffle furnace for calcination at 350°C for 2 hours;

[0028] (4) Repeat the above steps to prepare a four-layer film and put it i...

Embodiment 2

[0033] This embodiment 2 is implemented under the following conditions of implementation and technical requirements:

[0034] (1) Add 1.6g of concentrated hydrochloric acid dropwise to 3.13g of n-butyl titanate, mix with 0.65g of surfactant P123 in n-butanol after stirring for 10 minutes, and stir at 20°C for 3.5 hours to form a uniform and transparent sol- Gel Precursor.

[0035] (2) drip the prepared sol-gel precursor solution on a clean FTO conductive glass plate, add a moving airflow that forms an angle of 50 degrees with the FTO conductive glass plane, and adjust the wind speed to be 18 m / s. Under the action of , the sol solution forms a layer of titanium dioxide film;

[0036] (3) Put the prepared titanium dioxide film into a constant temperature and humidity box at 20°C and 75% relative humidity, age it for 30 hours, and then put it into a muffle furnace for calcination at 350°C for 2 hours;

[0037] (4) Repeat the above steps to prepare a three-layer film and put it ...

Embodiment 3

[0042] This embodiment 3 is implemented under the following conditions of implementation and technical requirements:

[0043] (1) Add 1.6g concentrated hydrochloric acid dropwise to 2.62g tetraisopropyl titanate, mix with 0.65g n-butanol solution of surfactant P123 after stirring for 20 minutes, and stir at 20°C for 4 hours to form a uniform and transparent sol - Gel Precursor.

[0044] (2) drip the prepared sol-gel precursor solution on a clean FTO conductive glass plate, add a moving airflow that forms an angle of 40 degrees with the FTO conductive glass plane, and adjust the wind speed to be 18 m / s. Under the action of , the sol solution forms a layer of titanium dioxide film;

[0045] (3) Put the prepared titanium dioxide film into a constant temperature and humidity box at 25°C and 70% relative humidity, age it for 40 hours, and then put it into a muffle furnace for calcination at 350°C for 2 hours;

[0046] (4) Repeat the above steps to prepare two layers of films and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com