Inorganic compound composite material, quantum dot light emitting diode and preparation method thereof

An inorganic compound and quantum dot luminescence technology, which is applied in chemical instruments and methods, luminescent materials, semiconductor/solid-state device manufacturing, etc., can solve problems such as poor contact between quantum dots and transport layer materials, and poor film uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

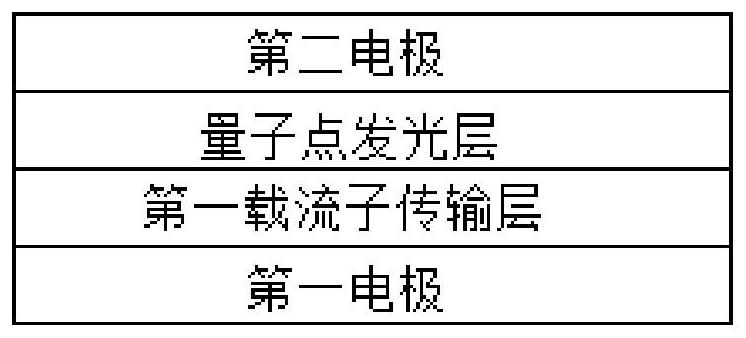

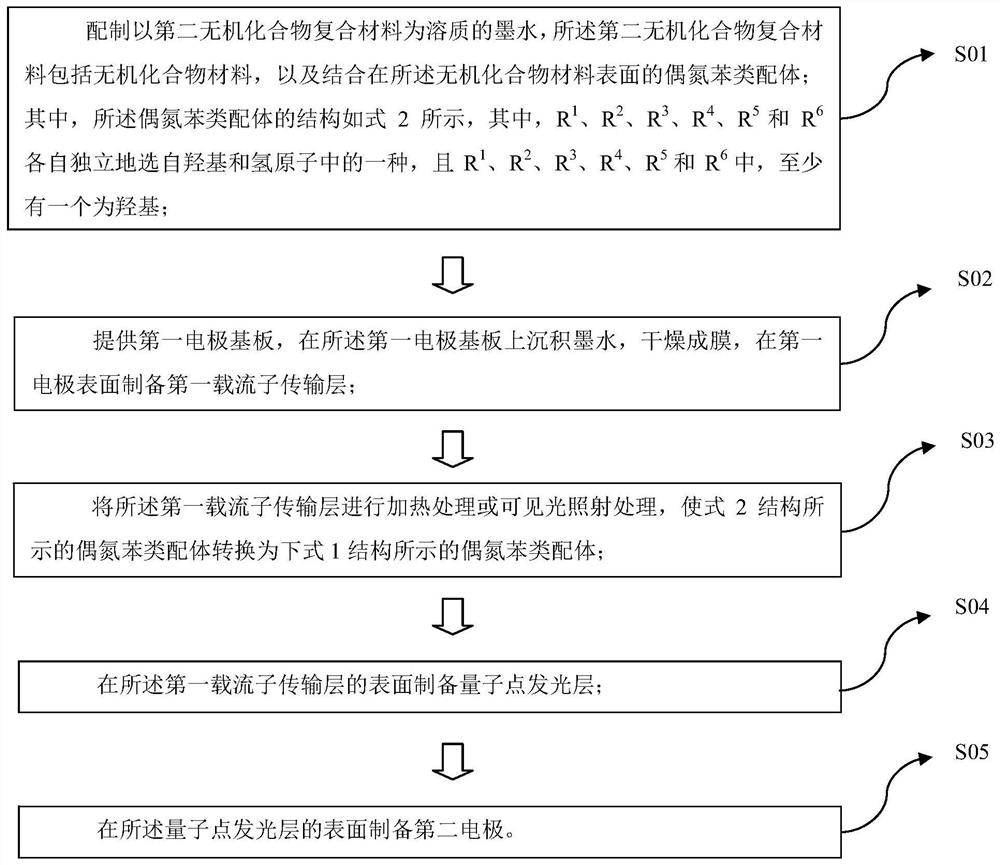

[0080] Such as figure 2 As shown, the third aspect of the embodiment of the present application provides a method for preparing a quantum dot light-emitting diode, comprising the following steps:

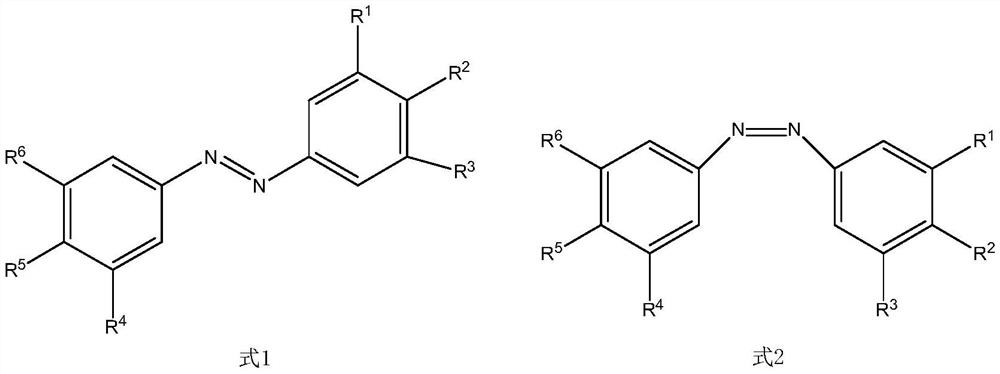

[0081] S01. prepare the ink with the second inorganic compound composite material as the solute, the second inorganic compound composite material includes the inorganic compound material, and the azobenzene ligand bound on the surface of the inorganic compound material; wherein, the azobenzene ligand The structure is shown in formula 2,

[0082]

[0083] Among them, R 1 , R 2 , R 3 , R 4 , R 5 and R 6 each independently selected from one of hydroxyl and hydrogen atoms, and R 1 , R 2 , R 3 , R 4 , R 5 and R 6 Among them, at least one is a hydroxyl group;

[0084] S02. Provide a first electrode substrate, deposit ink on the first electrode substrate, dry and form a film, and prepare a first carrier transport layer on the surface of the first electrode;

[0085] S03. ...

Embodiment 1

[0116] A method for preparing a quantum dot light-emitting diode, comprising the following steps:

[0117] Disperse zinc oxide nanoparticles in 10mL ethanol solution to form a 1.0mol / L solution, stir and dissolve at 25°C under an argon atmosphere, add 0.1mmol of trans-structure 3-hydroxyazobenzene after stirring for 10 minutes, React for 30 minutes; after the reaction is completed and cooled to room temperature, the zinc oxide nanoparticles are precipitated with ethyl acetate, ethanol, acetone and other solvents, washed and placed in a drying oven to dry;

[0118] Disperse zinc oxide nanoparticles with trans-structured 3-hydroxyazobenzene ligands on the surface in solvent-based ink, and irradiate with a 200w ultraviolet lamp for 30 minutes to make the trans-structured azobenzene ligands on the surface of oxide nanoparticles The body is transformed into a cis structure, and the polarity is enhanced; the ink is used as the precursor solution of the electron transport layer to pr...

Embodiment 2

[0121] A method for preparing a quantum dot light-emitting diode, comprising the following steps:

[0122] Disperse zinc oxide nanoparticles in 10mL ethanol solution to form a 1.0mol / L solution, stir and dissolve at 25°C under an argon atmosphere, and add 0.1mmol of trans-structure 3,5-hydroxyazo after stirring for 10 minutes Benzene, reacted for 30 minutes; after the reaction was completed and cooled to room temperature, zinc oxide nanoparticles were precipitated with ethyl acetate, ethanol, acetone and other solvents, washed and placed in a drying oven to dry;

[0123] Disperse zinc oxide nanoparticles with trans-structured 3,5-hydroxyazobenzene ligands on the surface in a solvent-based ink, and irradiate with a 200w UV lamp for 30 minutes to make the trans-structured azo on the surface of the oxide nanoparticles The benzene ligand is converted into a cis structure, and the polarity is enhanced; the ink is used as the precursor solution of the electron transport layer to pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com