A kind of thermally conductive composite diaphragm for battery and its application

A thermally conductive composite and separator technology, applied in the field of composite materials, can solve the problem of poor thermal conductivity of battery composite separators, and achieve the effect of achieving barrier effect, improving battery performance, and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

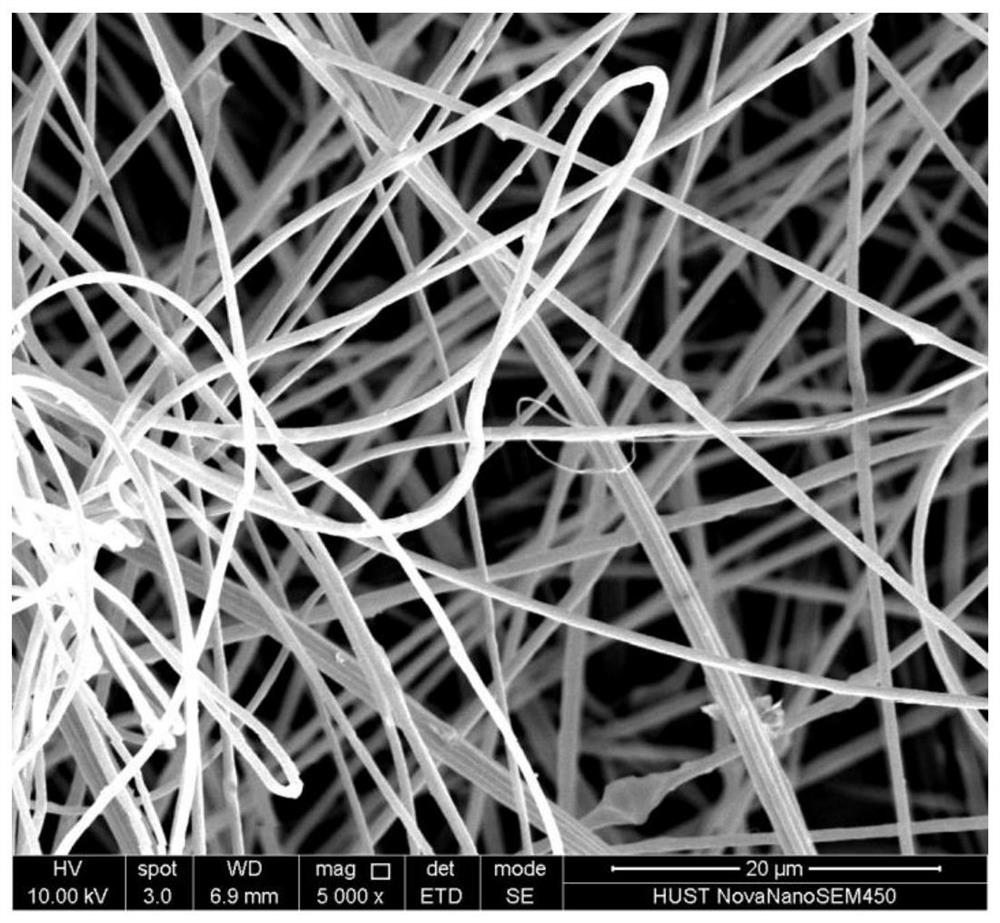

Embodiment 1

[0060] The invention discloses a heat-conducting composite diaphragm for a battery. This thermally conductive composite separator for batteries includes a polyolefin porous separator and an alumina / carbon hybrid fiber layer. The aluminum salt-polymer mixture is spun into fibers by electrospinning, and carbonized at high temperature under a protective atmosphere to form an alumina / carbon hybrid fiber layer, which is attached to the pole piece side of the polyolefin porous diaphragm . The polyolefin porous membrane is a polyethylene microporous membrane; the aluminum salt is aluminum nitrate; the polymer is polyacrylonitrile; the solution is N,N-dimethylformamide; The total mass fraction of the aluminum salt and the polymer in the aluminum salt-polymer mixed solution is 10%, wherein the mass ratio of the aluminum salt to the polymer is 1:1; the thickness of the prepared aluminum salt-polymer fiber film is 10 μm.

[0061] The preparation method of the thermally conductive compo...

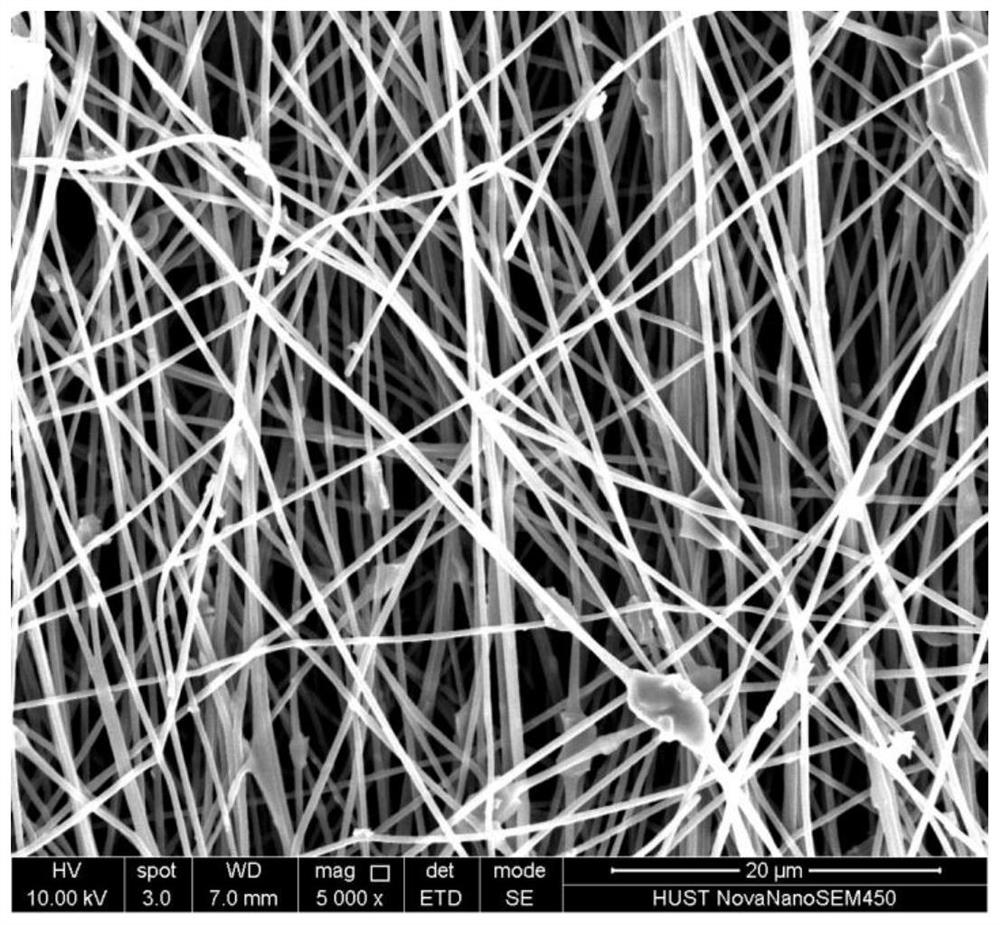

Embodiment 2

[0069] The invention discloses a heat-conducting composite diaphragm for a battery. This thermally conductive composite separator for batteries includes a polyolefin porous separator and an alumina / carbon hybrid fiber layer. The aluminum salt-polymer mixture is spun into fibers by electrospinning, and carbonized at high temperature under a protective atmosphere to form an alumina / carbon hybrid fiber layer, which is attached to the pole piece side of the polyolefin porous diaphragm . The polyolefin porous membrane is a polyethylene microporous membrane; the aluminum salt is aluminum tert-butoxide; the polymer is polyvinylpyrrolidone; the solution is water; the aluminum salt-polymer The total mass fraction of aluminum salt and polymer in the mixed solution is 25%, wherein the mass ratio of aluminum salt to polymer is 1:4, and the thickness of the prepared aluminum salt-polymer fiber film is 20 μm.

[0070] The preparation method of the thermally conductive composite separator ...

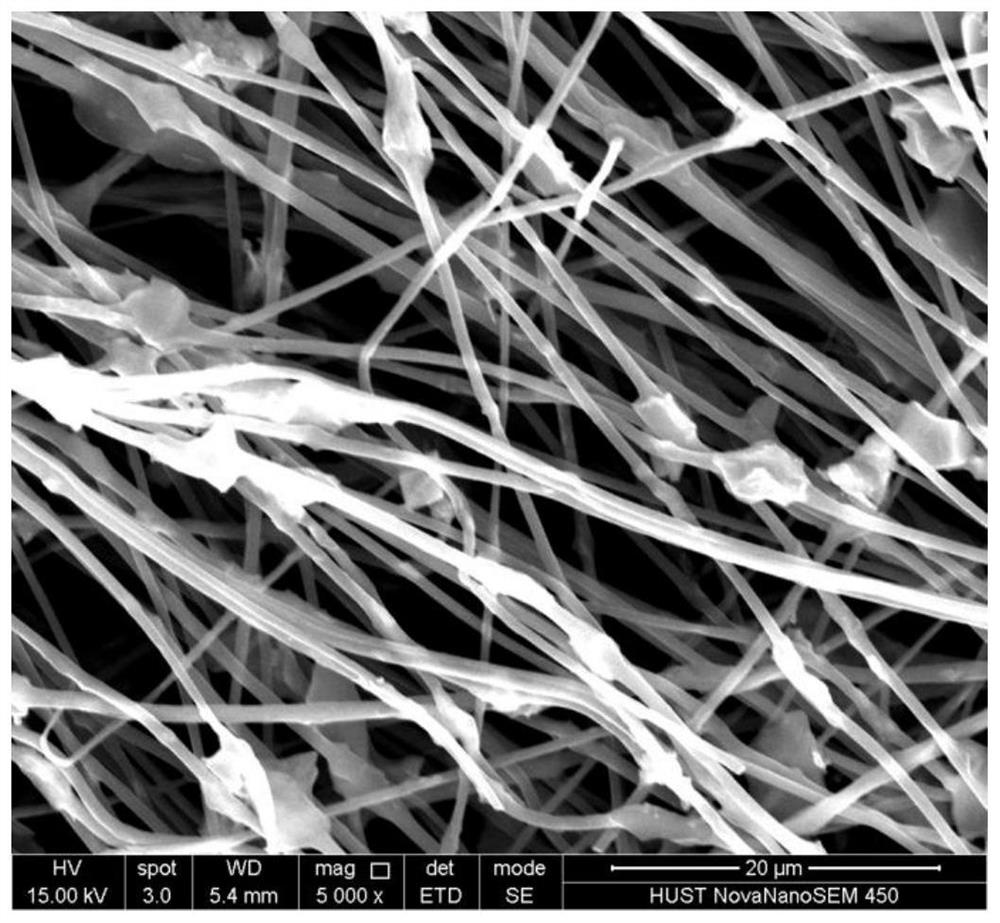

Embodiment 3

[0078] The invention discloses a heat-conducting composite diaphragm for a battery. This thermally conductive composite separator for batteries includes a polyolefin porous separator and an alumina / carbon hybrid fiber layer. The aluminum salt-polymer mixture is spun into fibers by electrospinning, and carbonized at high temperature under a protective atmosphere to form an alumina / carbon hybrid fiber layer, which is attached to both sides of the polyolefin porous membrane. The polyolefin porous diaphragm is polypropylene / polyethylene / polypropylene composite film; the aluminum salt is aluminum hydroxide; the polymer is polyvinyl butyral; the solution is ethanol; The total mass fraction of the aluminum salt and the polymer in the aluminum salt-polymer mixed solution is 50%, wherein the mass ratio of the aluminum salt to the polymer is 1:10, and the thickness of the aluminum salt-polymer fiber film obtained is 30 μm .

[0079] The preparation method of the thermally conductive c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com