Local forced circulation desalting method for multi-effect evaporating system

A technology of forced circulation and multi-effect evaporation, applied in the direction of multi-effect evaporation, general water supply saving, etc., can solve the problems of clogging pipelines, reducing the average temperature difference of heat exchangers, increasing salt concentration, etc., to prevent clogging, improve entrainment capacity, The effect of high flow rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

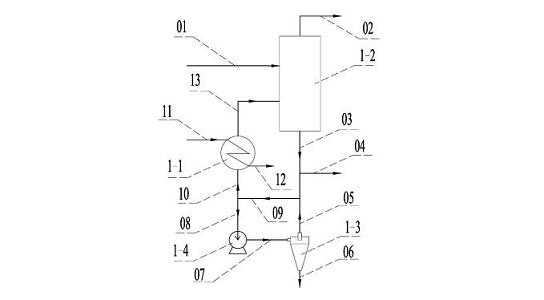

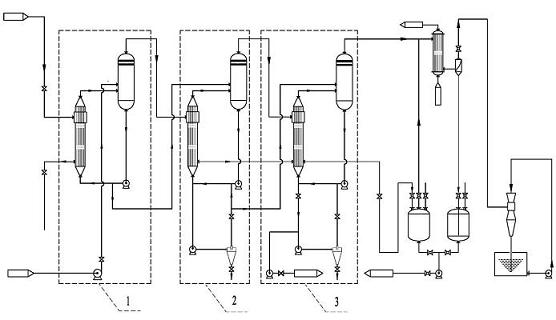

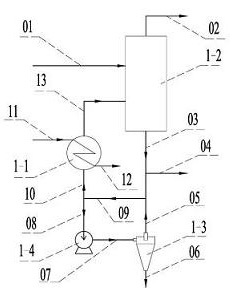

[0029] A workshop uses a downstream three-effect evaporation system to treat wastewater containing 15%wt sodium chloride. The treatment capacity is 4200 kg / h. The flow chart can be referred to figure 2 . Among them, the second and third effects have the function of local forced circulation desalination, and the corresponding external circulation and internal circulation processes can refer to figure 1 .

[0030] The operating temperature, average pressure and salt precipitation in the multi-effect evaporation system are shown in the table below.

[0031] Effectiveness

[0032] The second effect uses a head of 30m and a flow rate of 2m 3 / h centrifugal pump and matching hydrocyclone form the desalination external circulation process; the third effect adopts a lift of 30m and a flow rate of 15m 3 / h centrifugal pump and matching hydrocyclone form the desalination external circulation process. The fluid pressure head at the outlet of the third-effect circulating pu...

Embodiment 2

[0034] A workshop uses a pseudo-flow two-effect evaporation system to treat wastewater containing 25%wt sodium chloride. The treatment capacity is 3000 kg / h. Both effects have the function of local forced circulation desalination. The corresponding external circulation and internal circulation process can be referred to figure 1 .

[0035] The operating temperature, average pressure and salt precipitation in the multi-effect evaporation system are shown in the table below.

[0036] Effectiveness

[0037] The second effect uses a head of 30m and a flow rate of 2m 3 / h centrifugal pump and matching hydrocyclone form the desalination external circulation process; the third effect adopts a lift of 30m and a flow rate of 2m 3 / h centrifugal pump and matching hydrocyclone form the desalination external circulation process. Under the control of the valve in the outlet pipeline, the heavy phase can be smoothly discharged into the open salt slurry pool after passing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com