Packaging type corrugated enhanced laminated veneer lumber and manufacturing method thereof

A technology of laminated veneer lumber and corrugated type, applied in the direction of manufacturing tools, jointing of wooden veneers, chemical instruments and methods, etc., can solve the problem of increasing material consumption, power consumption and labor consumption, increasing packaging and transportation costs, damage Ecological environment and other issues, to achieve the effect of saving resources and harvesting, good dimensional stability, and protecting the ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

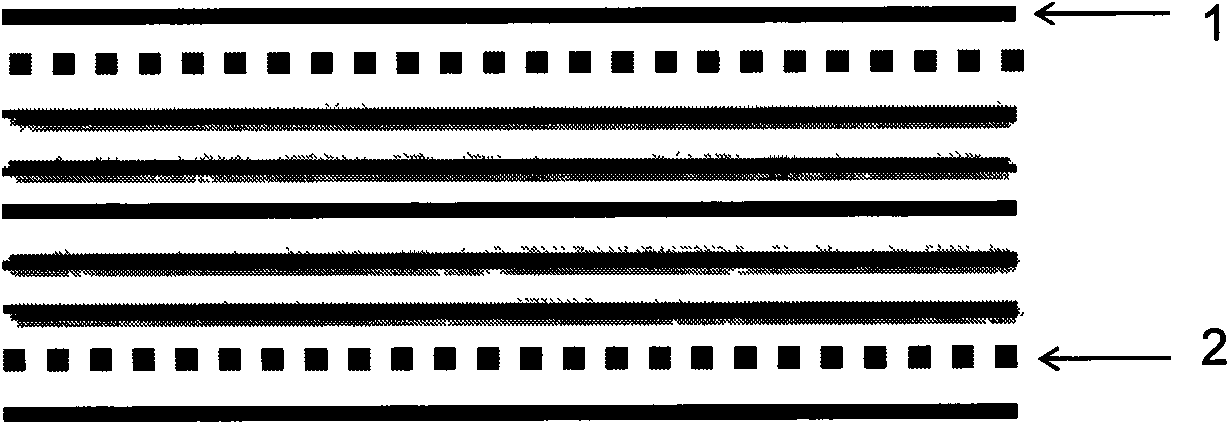

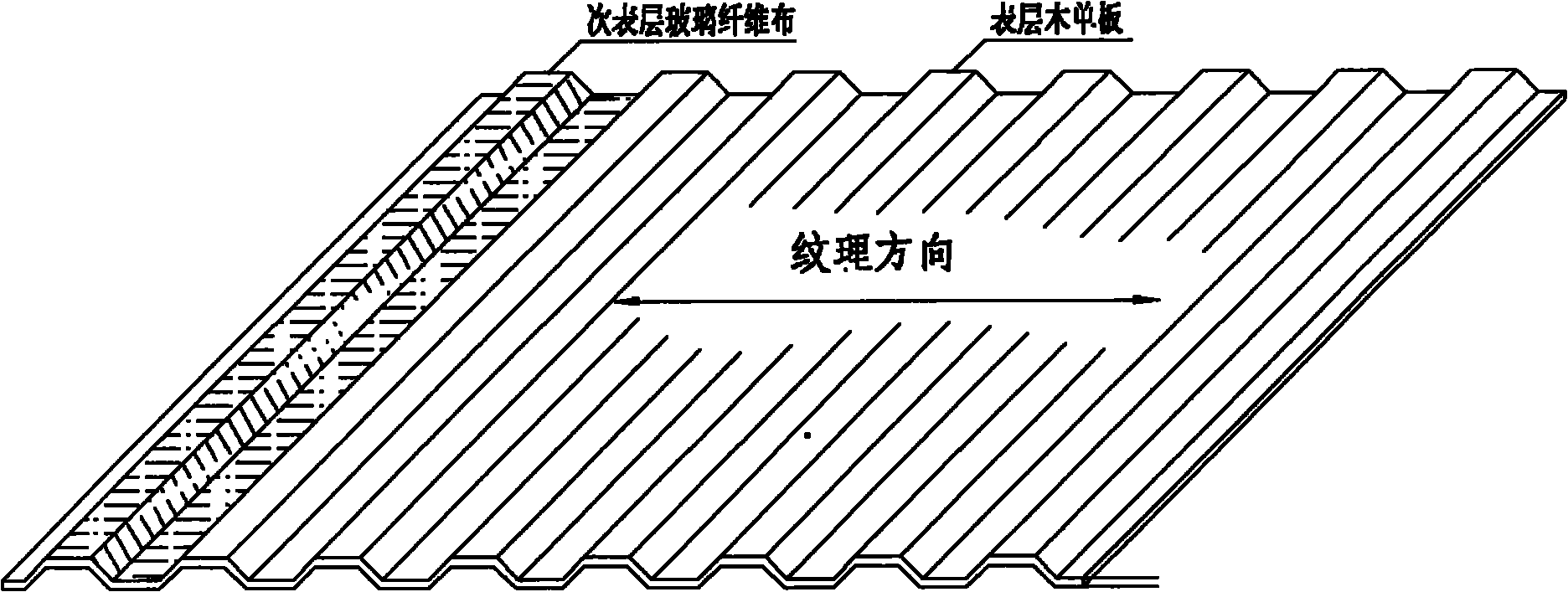

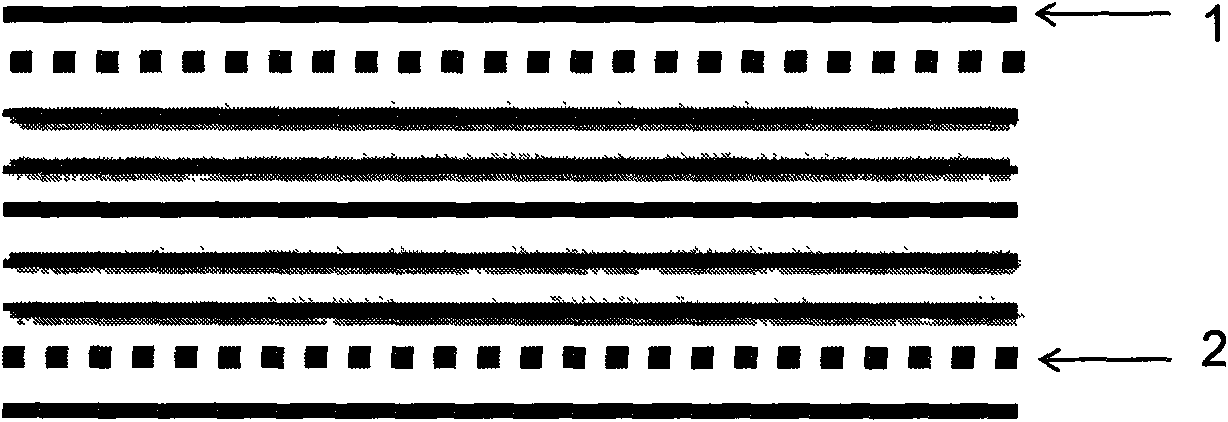

[0018] Example 1: A veneer with a thickness of 2.0mm is obtained by rotary cutting of fast-growing poplar wood section by a rotary cutting machine, and dried to a moisture content of 8%; alkaline glass fiber cloth is impregnated with phenolic resin glue, and the weight concentration of the glue solution for impregnation is 25%. The dipping time is 30m, and it is allowed to dry naturally; the poplar veneer is coated with phenolic resin, and the glue amount on one side is 150g / m 2 ; The glued veneer is manually assembled. The number of veneers is 9 layers, and the dipped glass fiber cloth is 2 layers. The grouping method is all the veneers along the grain. The glass fiber cloth is placed on the slab. The warp fibers of the fiber cloth are parallel to the fiber direction of the wood veneer. The composed slab is aged for 30mm at room temperature, and then sent to a hot press with a corrugated mold for hot pressing. The hot pressing temperature is 160℃, the hot pressing time is 90s / m...

Embodiment 2

[0019] Example 2: The fast-growing poplar wood section was peeled by a rotary cutting machine to obtain a veneer with a thickness of 3.0mm, and dried to a moisture content of 9%; the alkaline glass fiber cloth was impregnated with phenolic resin glue, and the weight concentration of the glue solution for impregnation was 30%. The immersion time is 10mim, and it is allowed to dry naturally; the poplar veneer is coated with phenolic resin, the glue amount on one side is 180g / m 2 ; The glued veneer is manually assembled. The number of veneers is 5 layers, and the dipped glass fiber cloth is 2 layers. The grouping method is all the veneers along the grain. The glass fiber cloth is placed on the slab. The warp fibers of the fiber cloth are parallel to the fiber direction of the wood veneer. The composed slab is aged for 45mim at room temperature, and then sent to a hot press with a corrugated mold for hot pressing. The hot pressing temperature is 150℃, the hot pressing time is 90s / mm...

Embodiment 3

[0020] Example 3: A veneer with a thickness of 2.0mm is obtained by rotary cutting of fast-growing poplar wood section by a rotary cutting machine, and dried to a moisture content of 10%; the alkaline glass fiber cloth is impregnated with urea-formaldehyde resin glue, and the weight concentration of the glue solution for impregnation is 50%. The dipping time is 30m, the alkaline glass fiber cloth is soaked with urea-formaldehyde resin glue and then dried naturally; poplar veneer is coated with urea-formaldehyde resin, and the glue amount on one side is 220g / m 2 ; The glued veneer is manually assembled. The number of veneers is 9 layers, and the dipped glass fiber cloth is 2 layers. The grouping method is all the veneers along the grain. The glass fiber cloth is placed on the slab. The warp fibers of the fiber cloth are parallel to the fiber direction of the wood veneer. The composed slab is aged 60mim at room temperature, and then sent to a hot press with a corrugated mold for h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com