Adsorption regeneration-photocatalysis advanced oxidation water treatment equipment

A treatment equipment and water oxidation technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of smaller specific surface area of catalysts, lower pollutant degradation efficiency, and lower operating costs Improvement and other issues, to achieve the effect of good catalytic reaction, large effective specific surface area, and thorough regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

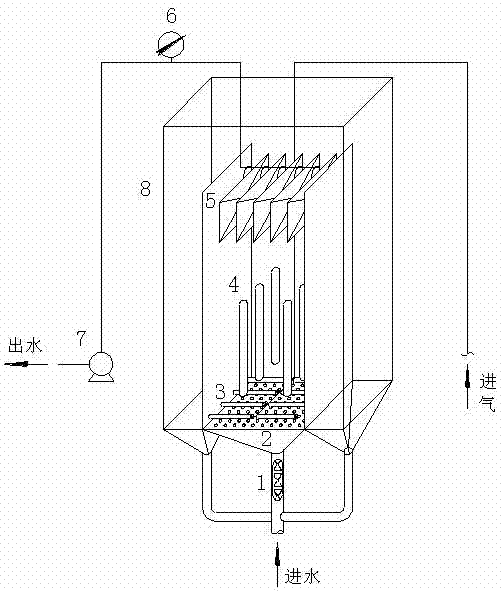

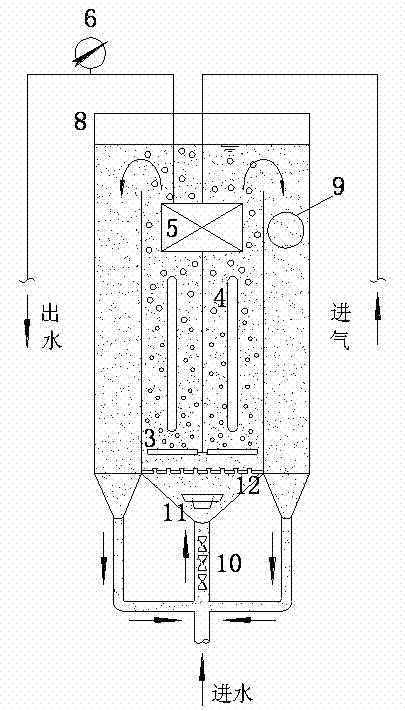

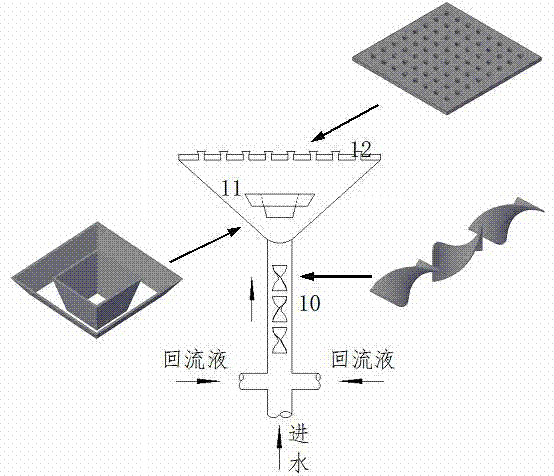

[0032] Embodiment 1: the working principle of the present invention is as figure 2 shown. The aeration tube 3, the ultraviolet light source 4 and the membrane module 5 are installed in the air-lift internal circulation reactor 8 to constitute the main part of the equipment of the present invention. The middle of the air-lift internal circulation reactor 8 is an upward circulation flow channel, and both sides are downward circulation flow channels, and the bottom of the downward circulation flow channel is connected to the front of the pipeline static mixer 1 through a pipeline. The membrane module 5 is connected to the water outlet pipe through a hose, and then the water is pumped out by the water outlet pump 7, and the vacuum gauge 6 is connected in series on the water outlet pipe. The powder photocatalyst 9 is suspended in the air-lift internal circulation reactor 8 . The spiral turbulence sheet 10 is placed in the water inlet pipe to form the pipeline static mixer 1 . T...

Embodiment 2

[0040] The invention is applied to the treatment of certain coking wastewater. The residence time of the reactor is 20h, the membrane module is made of polyvinylidene fluoride (PVDF), in the form of a flat membrane, and the operating flux of the membrane is 5~7 L / m 2 h, powder photocatalyst adopts Fe 2 o 3 , the dosage is 5g / L, and ozone aeration is supplemented. The influent COD concentration is 3031±571.2 mg / L, the effluent COD concentration is 303±47.2 mg / L, and the removal rate reaches 90%.

Embodiment 3

[0042] The invention is applied to the treatment of certain dye wastewater. The residence time of the reactor is 15h, the membrane module is made of polyvinylidene fluoride (PVDF), in the form of a flat membrane, and the operating flux of the membrane is 8~10 L / m 2 ·h, the powder photocatalyst uses ZnO, the dosage is 3g / L, supplemented with ozone aeration. The influent COD concentration is 1241±63.5 mg / L, the chromaticity is 230 degrees, the effluent COD concentration is 93±17.3 mg / L, the chromaticity is <20 degrees, and the removal rate reaches over 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com