Preparation method of new material for separating and purifying chiral tetramisole (TM)

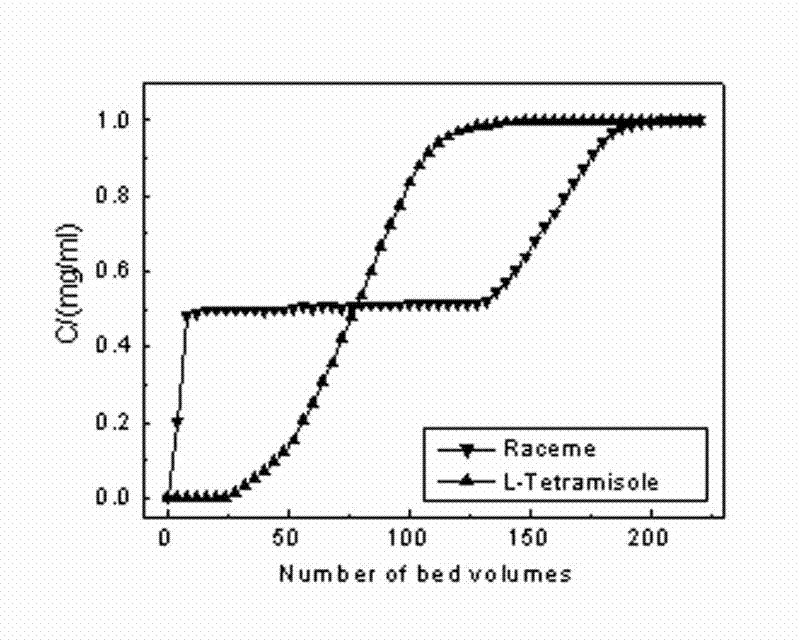

A technology of tetramisole and new materials, which is applied in the field of preparation of new materials for the separation and purification of chiral tetramisole, can solve the problems of low efficiency of surface imprinted materials, and achieve good selectivity, recognition and binding, and material utilization High, the effect of improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

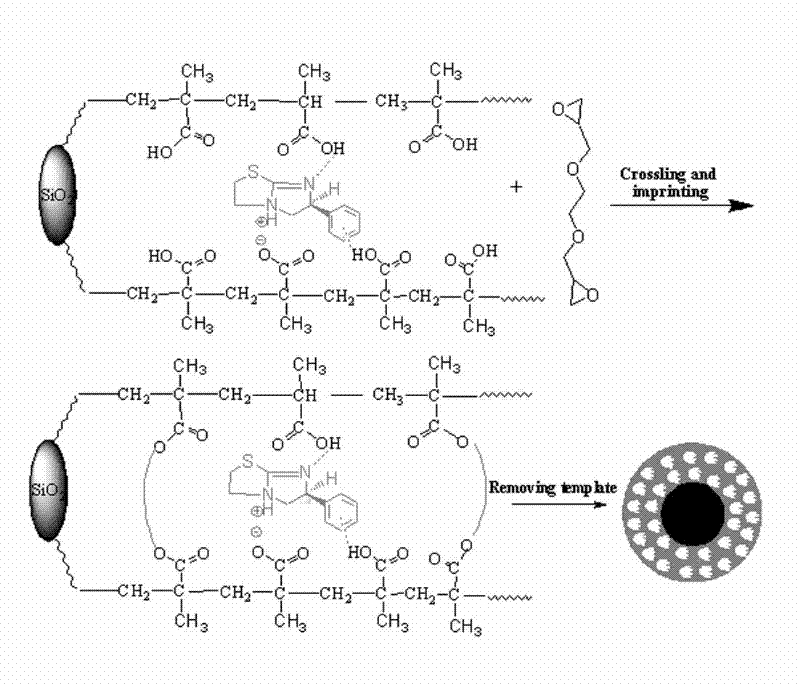

[0034] The preparation method of the new material used for separation and purification of chiral tetramisole comprises the following steps:

[0035] 1. Chemical surface modification of silica gel: Add 10g of activated silica gel to 120ml of water, and add 15ml of aminosilane coupling agent γ-aminopropyltrimethoxysilane (also can be γ-aminopropyltriethoxysilane) , reacted at 50 ° C for 20 h, and the product after suction filtration was washed repeatedly with ethanol and dried in vacuum to obtain surface-modified silica gel particles AMPS-SiO 2 ;

[0036] 2. Chemical grafting of polymethacrylic acid on the surface of silica gel particles: add 1 g of modified silica gel particles AMPS-SiO to a four-necked flask 2 , then add 80mL of water and 5mL of monomeric methacrylic acid, pass nitrogen for 30min to remove the air in the system, then raise the temperature of the system to 40°C, add 1.1% initiator ammonium persulfate whose mass is the mass of the monomer, and Carry out graft ...

Embodiment 2

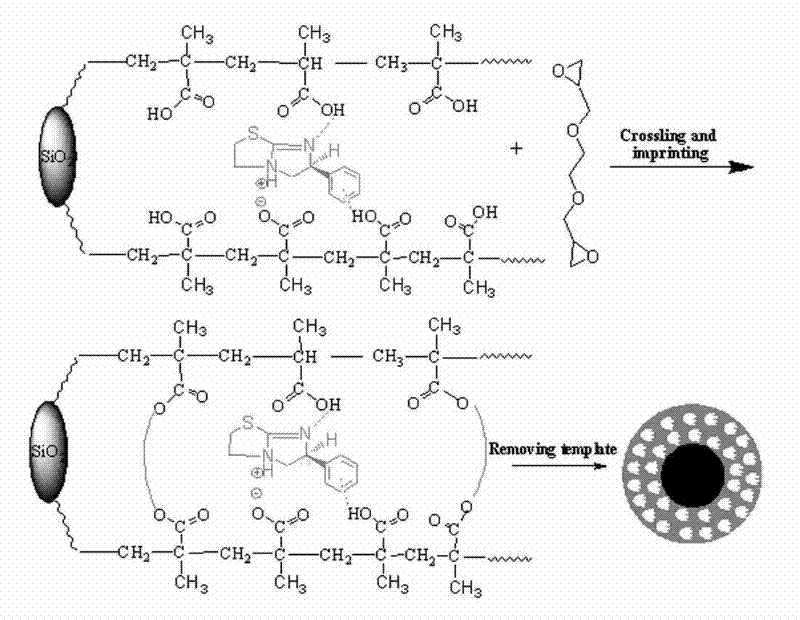

[0039] The preparation method of the new material used for separation and purification of chiral tetramisole comprises the following steps:

[0040] 1. Chemical surface modification of silica gel: Add 15g of activated silica gel to 100ml of water, and add 10ml of aminosilane coupling agent N-β(aminoethyl)-γ-aminopropyltrimethoxysilane (also can be N- β(aminoethyl)-γ-aminopropylmethyldimethoxysilane, N-β(aminoethyl)-γ-aminopropyltriethoxysilane, or N-β(aminoethyl)- γ-aminopropylmethyldiethoxysilane), reacted at 50°C for 22h, the product after suction filtration was repeatedly washed with ethanol, and dried in vacuum to obtain surface-modified silica gel particles AMPS-SiO 2 ;

[0041] 2. Chemical grafting of polymethacrylic acid on the surface of silica gel particles: add 1.5g of modified silica gel particles AMPS-SiO to a four-necked flask 2 , then add 90mL of water and 4.5mL of monomer methacrylic acid, pass nitrogen gas for 30min to remove the air in the system, then raise...

Embodiment 3

[0044] The preparation method of the new material used for separation and purification of chiral tetramisole comprises the following steps:

[0045] 1. Chemical surface modification of silica gel: add 13g of activated silica gel to 150ml of water, and add 13ml of aminosilane coupling agent anilinomethyltrimethoxysilane (also can be anilinomethyltriethoxysilane, or ammonia Ethylaminopropyltrimethoxysilane), reacted at 50°C for 24h, the product after suction filtration was repeatedly washed with ethanol, and dried in vacuum to obtain surface-modified silica gel particles AMPS-SiO 2 ;

[0046] 2. Chemical grafting of polymethacrylic acid on the surface of silica gel particles: add 1.2g of modified silica gel particles AMPS-SiO to a four-neck flask 2 , then add 100mL of water and 4mL of monomer methacrylic acid, pass nitrogen gas for 30min to remove the air in the system, then raise the temperature of the system to 40°C, add 1.2% initiator ammonium persulfate whose mass is the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com