Method for preparing corncob-base polyurethane rigid foam damping material

A rigid foam and polyurethane technology, which is applied in the field of preparing corncob-based polyurethane rigid foam damping materials, can solve the problems of poor polyurethane foam performance, increased liquefaction cost, long liquefaction time, etc. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

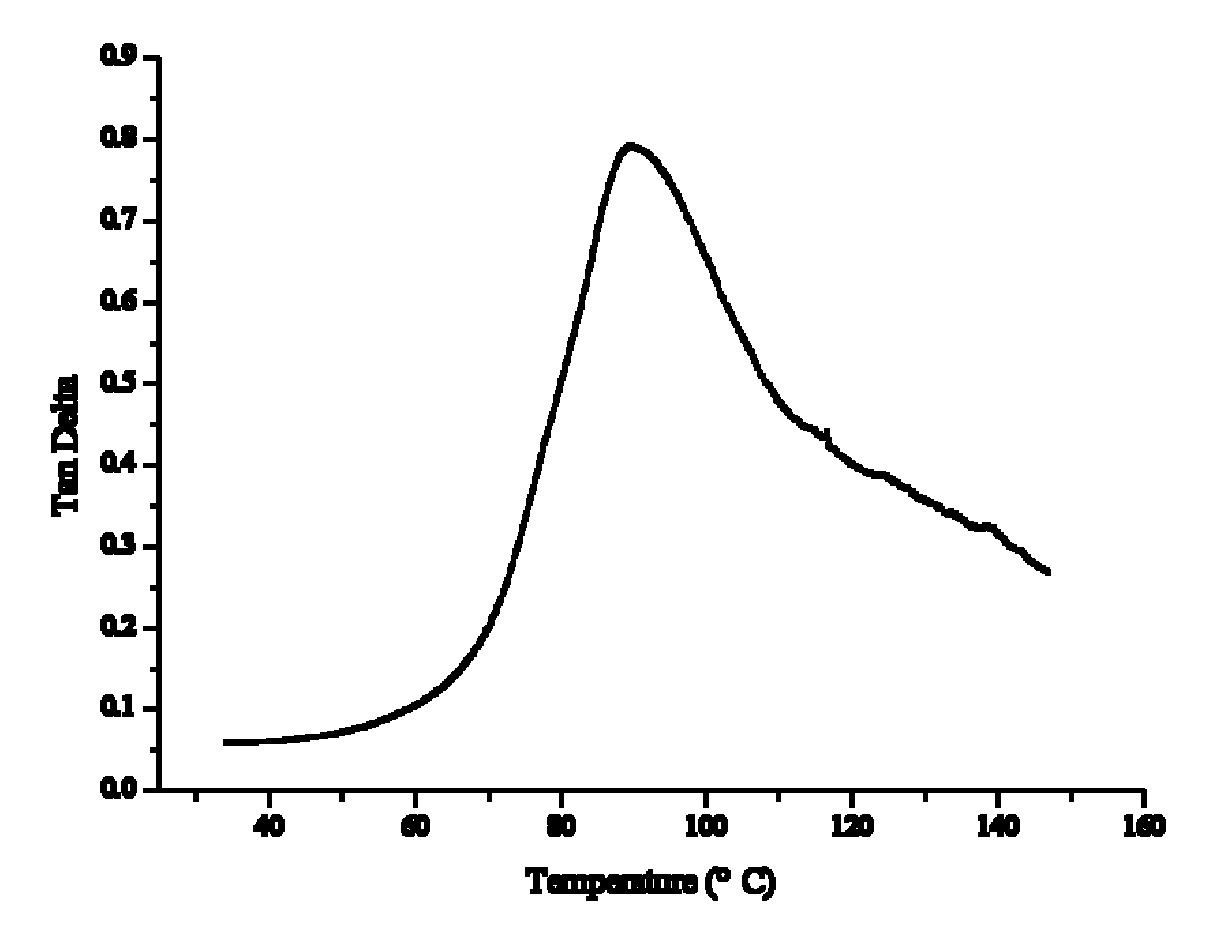

[0031] Embodiment 1, preparation corn cob base polyurethane rigid foam

[0032] Add 96 parts by weight of polyethylene glycol 400, 24 parts by weight of glycerol and 8.4 parts by weight of mass concentration of 72% sulfuric acid into the reaction vessel, stir evenly, heat up to 160 ° C, add 30 parts of crushed corn cobs (particle diameter 20-80 mesh), stirred and reacted for 60 minutes, and immediately cooled with cold water after taking it out to obtain a liquefied product.

[0033] Take out 100 parts by weight of the above liquefied product, add 1.5 parts by weight of magnesium oxide to neutralize excess acid, and then place it at 105° C. for 10 h to remove moisture. Take 50 parts by weight of the treated liquefied product in a paper cup, add 0.26 parts by weight of dibutyltin dilaurate, 0.24 parts by weight of triethylamine and 0.51 parts by weight of silicone oil, stir at 1300r / min for 60s, then add 50 parts by weight of The PAPI was stirred at the same speed for 30s (app...

Embodiment 2

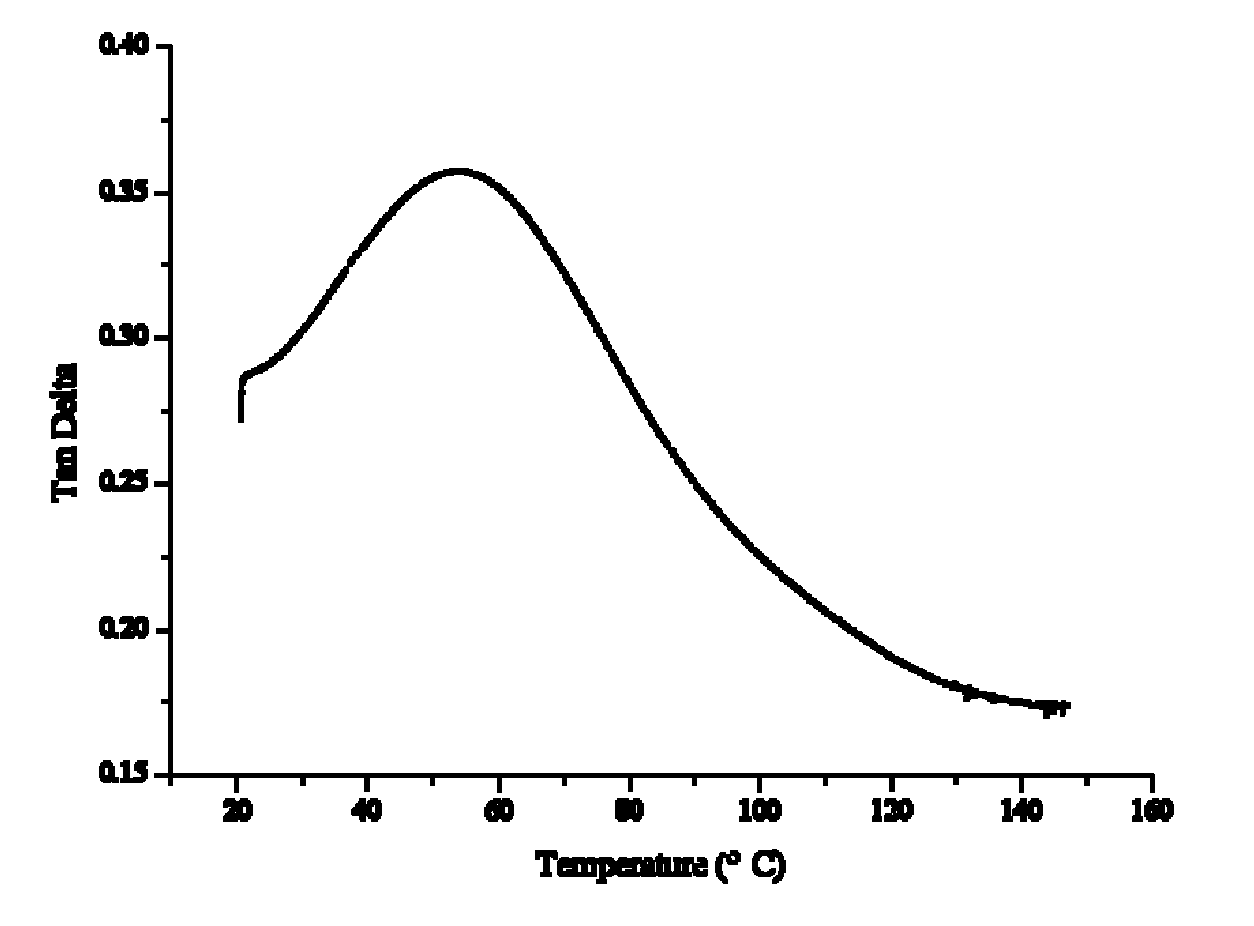

[0035] Embodiment 2, preparation corncob base polyurethane rigid foam

[0036] Add 80 parts by weight of polyethylene glycol 400, 40 parts by weight of glycerol and 4.2 parts by weight of sulfuric acid with a concentration of 98% into the reaction vessel, stir evenly, heat up to 130° C., add 30 parts of crushed corncobs (particle diameter 20 -80 mesh), stirred and reacted for 60 minutes, and immediately cooled with cold water after taking out to obtain the liquefied product.

[0037] Take out 100 parts by weight of the above liquefied product, add 2 parts by weight of magnesium oxide to neutralize excess acid, and then place it at 105° C. for 12 hours to remove moisture. Take 50 parts by weight of the treated liquefied product in a paper cup, add 0.25 parts by weight of dibutyltin dilaurate, 0.26 parts by weight of triethylamine and 0.48 parts by weight of silicone oil, stir at 1200r / min for 60s, then add 50 parts by weight of The PAPI was stirred at the same speed for 20s (a...

Embodiment 3

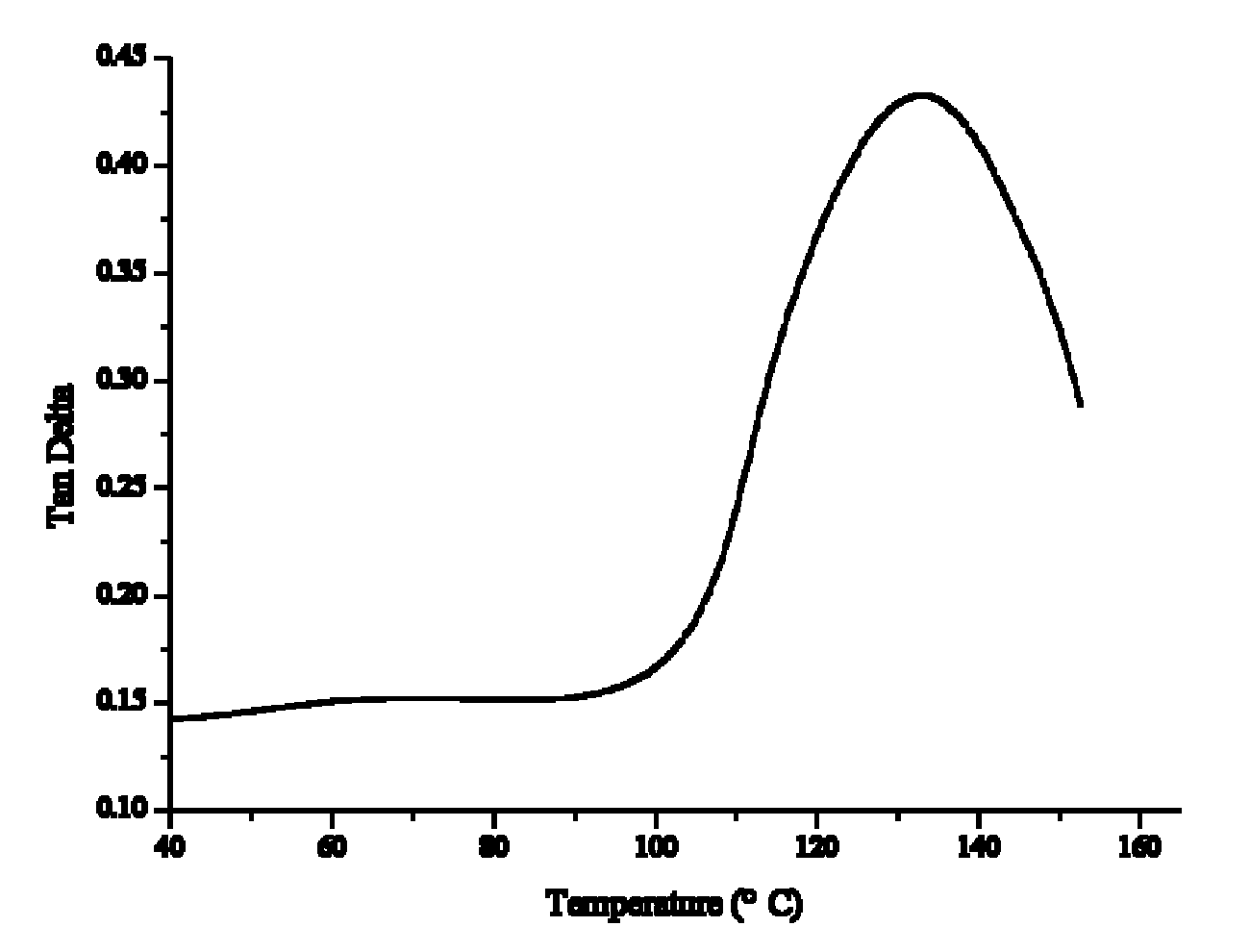

[0039] Embodiment 3, preparation corn cob base polyurethane rigid foam

[0040] Add 12 parts by weight of polyethylene glycol 400, 108 parts by weight of glycerin and 4.2 parts by weight of sulfuric acid with a concentration of 98% into the reaction vessel, stir evenly, heat up to 160° C., add 30 parts of crushed corn cobs (particle diameter 20 -80 mesh), stirred and reacted for 60 minutes, and immediately cooled with cold water after taking out to obtain the liquefied product.

[0041]Take out 100 parts by weight of the above liquefied product, add 2 parts by weight of magnesium oxide to neutralize excess acid, and then place it at 105° C. for 11 hours to remove moisture. Take 50 parts by weight of the treated liquefied product in a paper cup, add 0.27 parts by weight of dibutyltin dilaurate, 0.24 parts by weight of triethylamine and 0.53 parts by weight of silicone oil, stir at 1000r / min for 60s, then add 50 parts by weight of The PAPI was stirred at the same speed for 60s ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com