Polyphenyl ether elastomer composition and preparation method thereof

A polyphenylene ether elastomer and composition technology, applied in the polymer field, can solve the problems of insufficient strength and heat resistance, and achieve the effects of making up for rapid decline, making up for technical defects, high heat resistance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

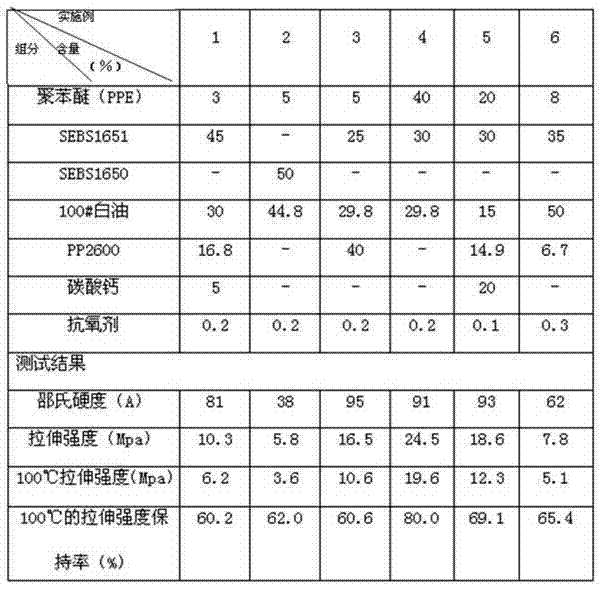

Examples

Embodiment 1~6

[0028] In the following examples,

[0029] The intrinsic viscosity (Ⅳ) measured by polyphenylene ether (PPE) in toluene at 25°C when the concentration is 0.6g / 100ml is 0.33dl / g;

[0030] G-1651 is a styrene / ethylene-butylene / styrene block copolymer (SEBS) available from Kraton Polymers under the trade name Kraton G 1651;

[0031] G-1650 is a styrene / ethylene-butylene / styrene block copolymer (SEBS) available from Kraton Polymers under the trade name Kraton G 1650;

[0032] 100# white oil is naphthenic oil produced by Xinjiang Karamay Petrochemical, and its mass content of naphthenes is 45%;

[0033] PP2600 is a homopolypropylene with a melt index of 26g / 10min (230℃×2.16kg);

[0034] The antioxidant is tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester, which is purchased from Ciba Specialty Chemicals under the trade name of Irganox 1010.

[0035] The preparation method of polyphenylene ether elastomer composition in each embodiment comprises the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com