Process for manufacturing steel forge piece of vertical conveying pipe of deep sea oil extraction equipment

A manufacturing process and technology for steel forgings, which is applied in the field of steel forgings manufacturing process for deep-sea oil production equipment delivery risers, can solve the problems that the low-temperature toughness is difficult to meet the requirements and cannot be used in low-temperature working conditions, and achieves saving forging equipment occupancy rate, one-time delivery The effect of improving the inspection pass rate and reducing the number of upsets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment (

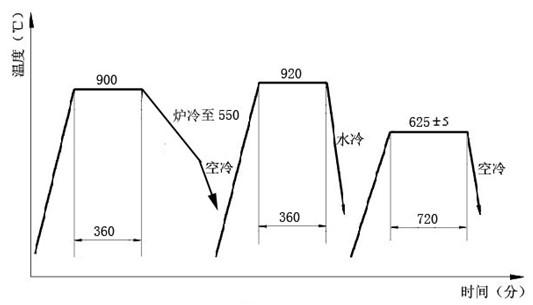

[0059] Embodiment (process number C), the specific steps are as follows:

[0060] Step C①: Using chromium-molybdenum low-alloy steel as a blank, the chromium-molybdenum low-alloy steel blank is smelted by the process of primary smelting in an electric furnace, refining outside the furnace, and vacuum degassing. The chromium-molybdenum low-alloy steel is composed of carbon, silicon, manganese , chromium, molybdenum, phosphorus, sulfur, hydrogen, nickel, niobium, vanadium, titanium, copper and aluminum, its mass percentage is:

[0061] 0.12%≤carbon≤0.15%, 0.15%≤silicon≤0.40%, 0.50%≤manganese≤0.60%, 2.25%≤chromium≤2.50%, 1.00%≤molybdenum≤1.10%, phosphorus≤0.020%, sulfur≤0.015%, Hydrogen≤2.0ppm, 0.20%≤nickel≤0.50%, 0<niobium≤0.01%, 0<vanadium≤0.01%,

[0062] 0<titanium≤0.025%, 0<copper≤0.20%, 0<aluminum≤0.05%, and the total amount of titanium, copper and aluminum≤0.50%,

[0063] Step C②: Select the square ingot according to the size of the required structural parts, put it into ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com