Method for analyzing 7N electronic grade ultrapure ammonia

An analysis method, ultra-pure ammonia technology, applied to the analysis method and system field of trace components in ultra-high-purity ammonia gas, it can solve problems affecting column efficiency, reduce the service life of the detector, prolong the analysis cycle, etc., and achieve quantitative Accurate, low detection limit, short analysis cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

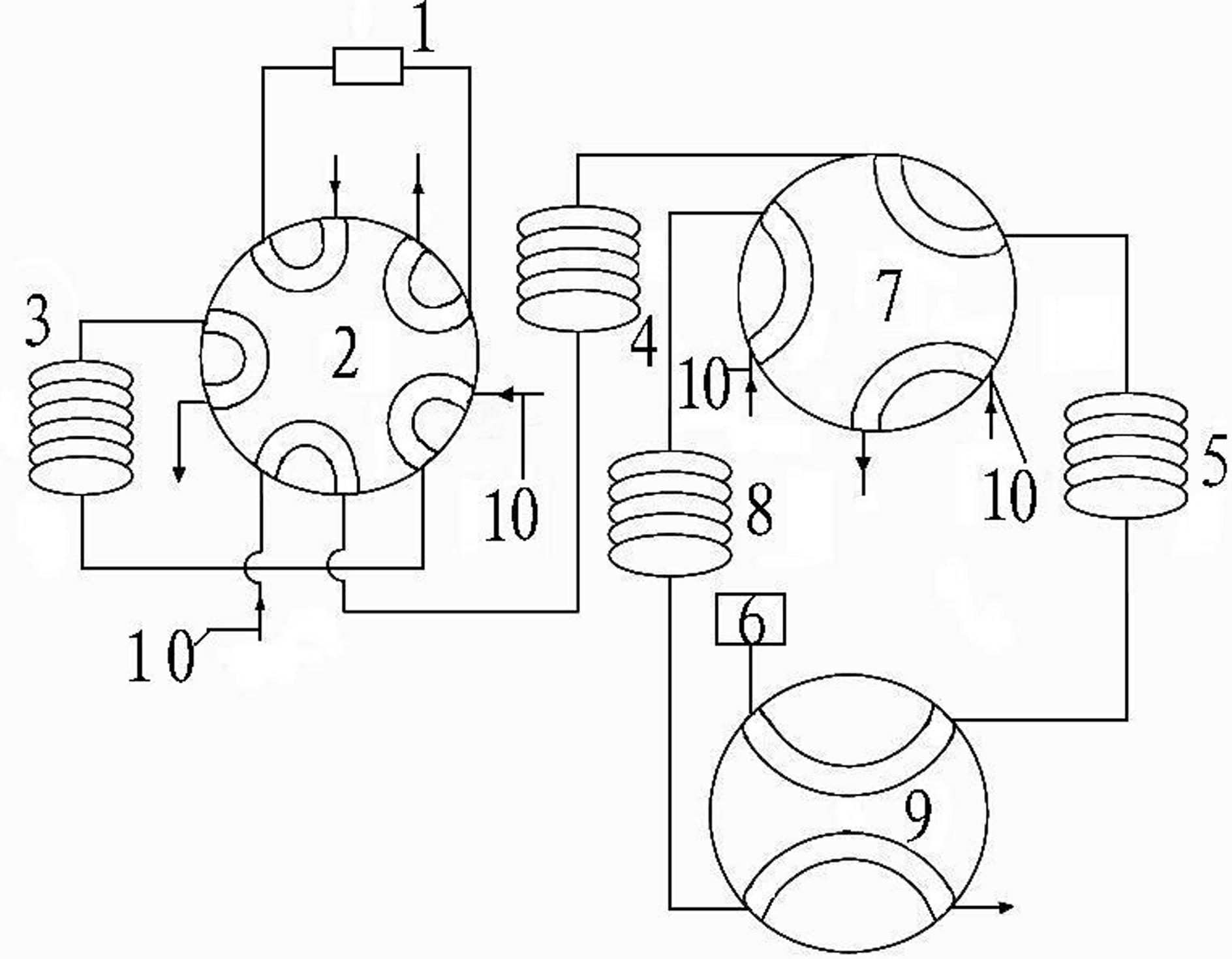

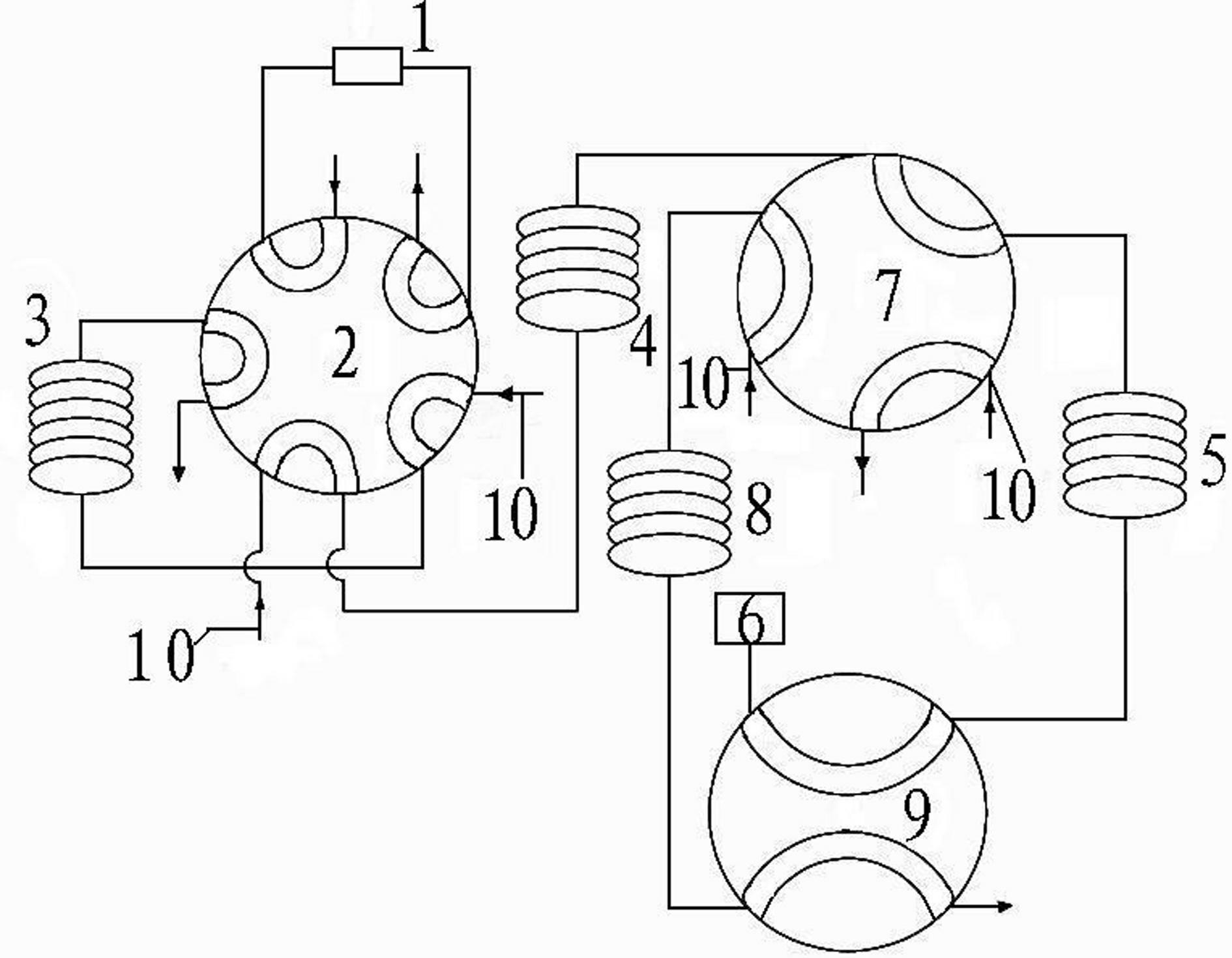

[0022] Below, refer to the attached figure 1 The present invention will be described.

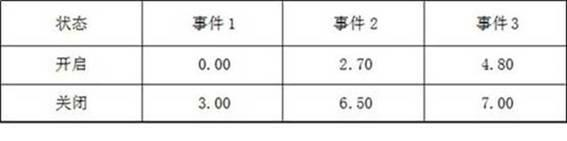

[0023] Use 7N electronic grade ultra-pure ammonia gas as the sample, and replace the quantitative tube (1) with the sample at a flow rate of 0.1MPa and 350mL / min. After 1 min of replacement, start the operating procedure. Open the ten-way valve (2) at 0.00min, and the carrier gas (10) sends the sample gas into the pre-separation column I (3). The sample gas is separated in the pre-separation column I, and the separation order is mixed peaks (H 2 , O 2 +Ar+N 2 +CO,CH 4 ), CO 2 , NH 3 . mixed peak (H 2 , O 2 +Ar+N 2 +CO,CH 4 ) first passes through the pre-separation column I and the pre-separation column II (4), is analyzed in the analytical column I (5), and is detected by the DID detector (6). To ensure that the last component CH in the mixed peak 4 into the analytical column I (5) and CO 2 When there is no flow out of the pre-separation column II (4), open the six-way valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com