Method for comprehensive utilization of coal gangue

A coal gangue and material technology, which is applied in the field of comprehensive utilization of coal gangue, can solve the problems of using, not being able to use photovoltaic cutting blades, and the quality of silicon carbide is not high

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

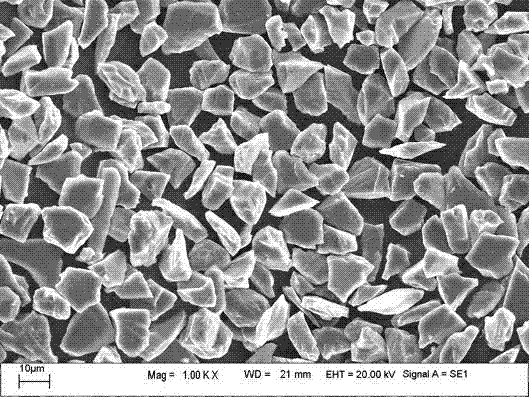

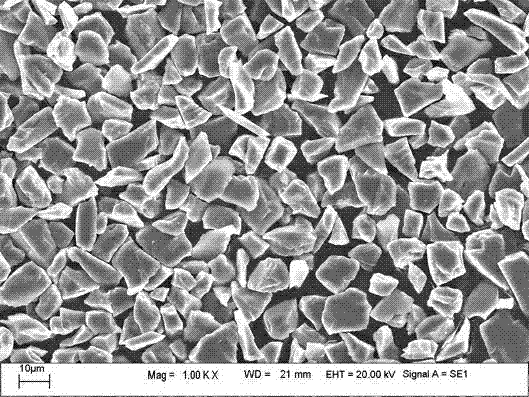

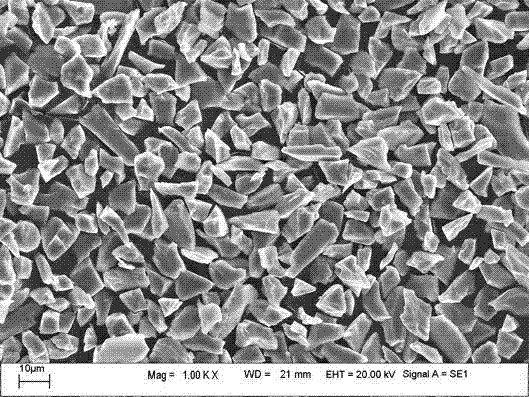

Image

Examples

Embodiment 1

[0027] The steps of preparing polyaluminum chloride:

[0028] (1) Crush and finely grind the gangue to 0.10mm;

[0029] (2) Put the pulverized coal gangue powder in a high-temperature tube furnace, and activate it by pyrolysis at 600°C for 1 hour. A small amount of organic matter in the gangue can not only act as part of the heat source, but also reduce the impact of carbon in the gangue on the extraction of chlorine. The influence of the quality of aluminum;

[0030] (3) The activated coal gangue powder is acid-dissolved with hydrochloric acid at 100°C for 4 hours, the mass ratio of solid to liquid is 1:4, the aluminum in the powder is dissolved in the acid in the form of aluminum chloride, and other traces of iron, calcium, magnesium, etc. The oxide also enters the solution in the form of chloride, and the leaching rate of aluminum chloride is over 90%;

[0031] (4) After solid-liquid separation, the filtrate is matured, hydrolyzed and polymerized, and the basicity is adju...

Embodiment 2

[0042] The steps of preparing polyaluminum chloride:

[0043] (1) Crush and finely grind the gangue to 0.08mm;

[0044] (2) Put the pulverized coal gangue powder in a fluidized fluidized furnace, and activate it by pyrolysis at 650°C for 0.8 hours; a small amount of organic matter in the gangue can not only act as part of the heat source, but also reduce the impact of carbon in the gangue on the quality of aluminum chloride extracted Impact;

[0045] (3) The activated gangue powder is dissolved in hydrochloric acid at 0.4MPa and 145°C for 3 hours, the mass ratio of solid to liquid is 1:4, the aluminum in the powder is dissolved in the acid in the form of aluminum chloride, other trace iron, Oxides such as calcium and magnesium also enter the solution in the form of chloride, and the leaching rate of aluminum chloride is over 90%;

[0046] (4) After solid-liquid separation, the filtrate is matured, hydrolyzed and polymerized, and the basicity is adjusted with calcium aluminat...

Embodiment 3

[0057] The steps of preparing polyaluminum chloride:

[0058] (1) Crush and finely grind the gangue to 0.08mm;

[0059] (2) Put the pulverized coal gangue powder in a high-temperature tube furnace, and activate it by pyrolysis at 800°C for 0.5 hours; a small amount of organic matter in coal gangue can not only act as part of the heat source, but also reduce the impact of carbon in coal gangue on the extraction of chlorine. The influence of the quality of aluminum;

[0060] (3) The activated coal gangue powder is acid-dissolved with hydrochloric acid at 110°C for 1 hour, the mass ratio of solid to liquid is 1:4, the aluminum in the powder is dissolved in the acid in the form of aluminum chloride, and other traces of iron, calcium, magnesium, etc. The oxide also enters the solution in the form of chloride, and the leaching rate of aluminum chloride is over 90%;

[0061] (4) After solid-liquid separation, the filtrate is matured, hydrolyzed and polymerized, and the basicity is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com