Method for synthesizing mesoporous mordenite

A technology of mordenite and synthesis method, which is applied in the direction of mercerized crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, etc., can solve the problems of complex synthesis process, difficulty in obtaining, high price, etc., and achieve simple synthesis process and low consumption , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

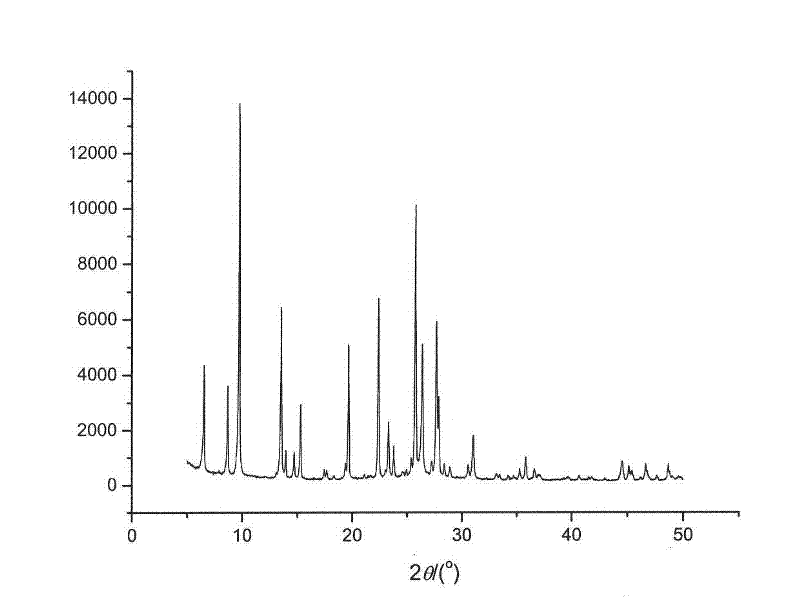

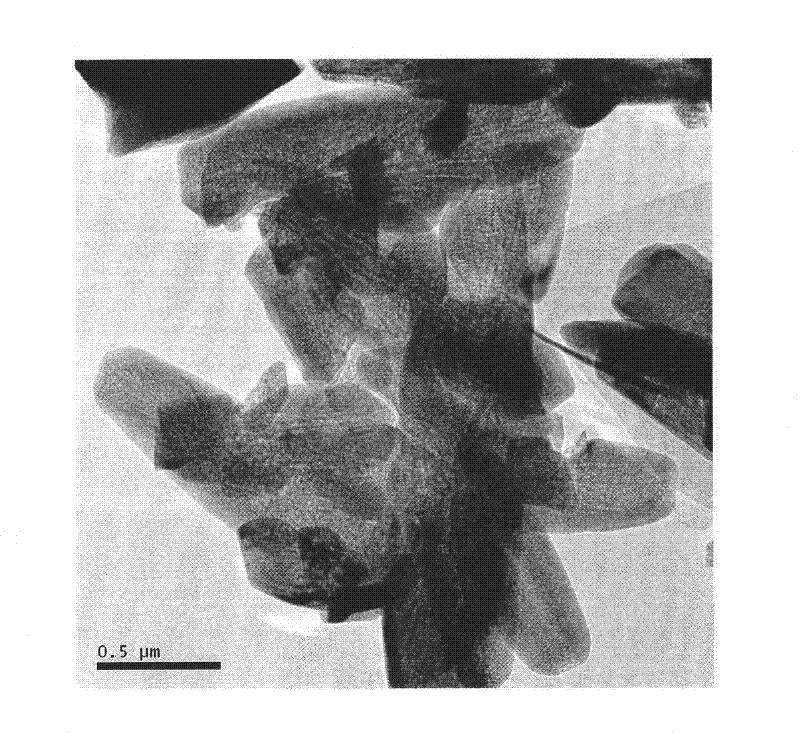

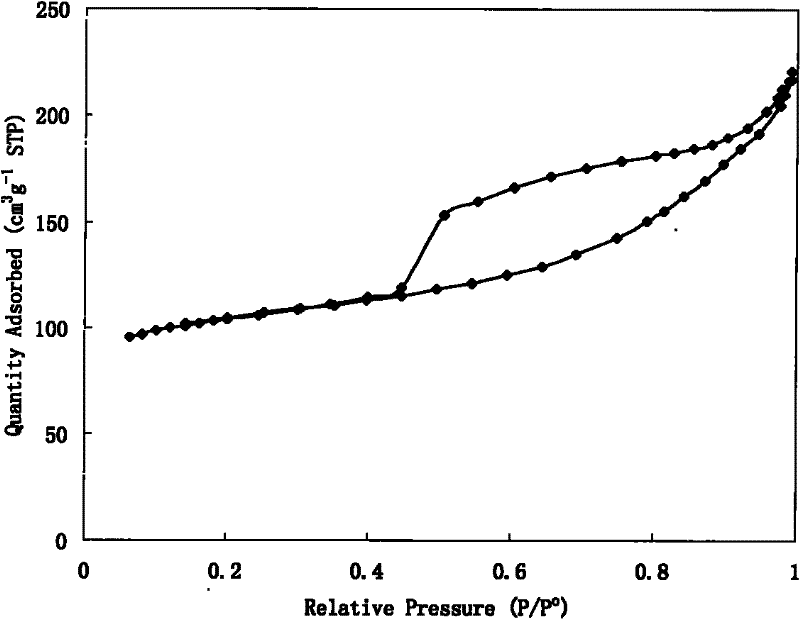

[0018] 213.7 grams of silica sol [containing 40% (weight) SiO 2 , the same below] is solution A, 81.0 grams of solid aluminum sulfate [chemically pure, Al 2 (SO 4 ) 3 18H 2 O, the same below] was dissolved in 140 milliliters of water to obtain B solution. 54.5 grams of solid sodium hydroxide (chemically pure) was dissolved in 300 milliliters of water to obtain solution C. Under stirring, solution A and solution B were added to solution C in parallel flow, and the two solutions were added simultaneously within 45 to 90 minutes. Add 85.48 grams of starch again, continue to stir for more than 1 hour, then add 8.3 grams of ammonia [chemically pure, containing 25.5% (weight) NH 3 ], and then stirred for 1 to 3 minutes. Then transfer the slurry into a crystallization tank with a stirring device, seal the crystallization tank, turn on the stirring device, and crystallize at a constant temperature of 190°C for 28 hours to obtain a crystallization product. The crystalline product...

Embodiment 2

[0021] 230.4 grams of silica sol is A solution, 56.3 grams of solid aluminum nitrate [chemically pure, Al(NO 3 ) 3 9H 2 O, the same below] was dissolved in 400 milliliters of water to obtain B solution. Dissolve 19.75 grams of tetraethylammonium bromide (TEABr) [chemically pure, the same below] in 700 milliliters of water under stirring, and then add 33 grams of solid sodium hydroxide to obtain solution C. Slowly add solution B and solution A to solution C in sequence, then add 165 grams of cellulose, and continue stirring for more than 1 hour. Then transfer the slurry into a crystallization kettle with a stirring device, seal the crystallization kettle, turn on the stirring device, and crystallize at a constant temperature of 120° C. for 9 days to obtain a crystallization product. The crystallized product was cooled, filtered and washed, dried at 100°C for 6 hours, and calcined at a constant temperature of 550°C for 4 hours to obtain a mesoporous mordenite product. Produc...

Embodiment 3

[0024] 230.8 grams of industrial water glass [containing 26% (weight) SiO 2 , 7.45% (weight) Na 2 O, the same below] is A solution, and 27.2 grams of solid aluminum sulfate is dissolved in 300 milliliters of water to obtain B solution. Get 118 grams of 25% (weight) tetraethylammonium hydroxide (TEAOH) solution, under agitation, A solution and B solution are simultaneously added in parallel, after the two solutions are added simultaneously, continue to stir for more than 15 minutes, add polyethylene glycol 30 g, continue stirring for more than 1 hour. Then transfer the slurry into a crystallization kettle with a stirring device, seal the crystallization kettle, turn on the stirring device, and crystallize at a constant temperature of 170° C. for 3 days to obtain a crystallization product. The crystalline product was cooled, filtered and washed, dried at 120°C for 4 hours, calcined at a constant temperature of 220°C for 2 hours, and then heated to 550°C for 2 hours to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com