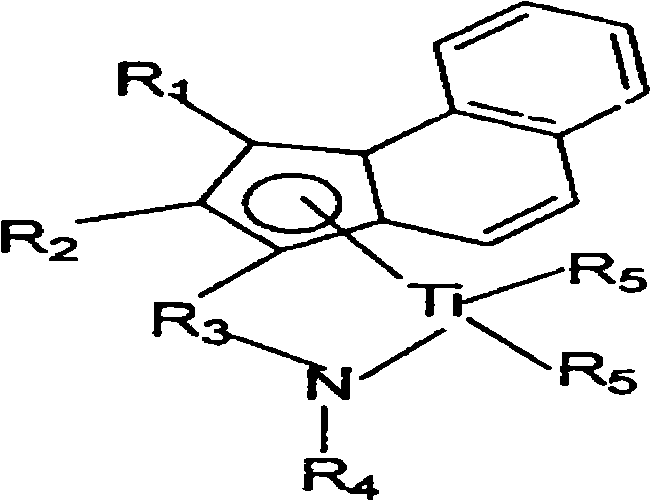

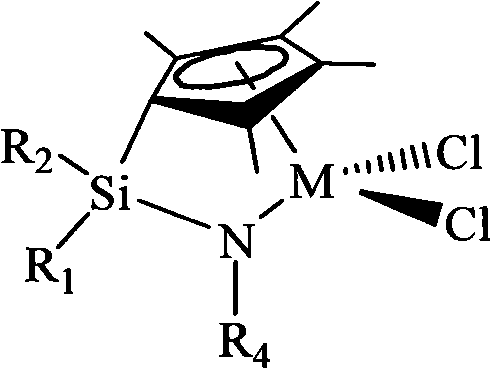

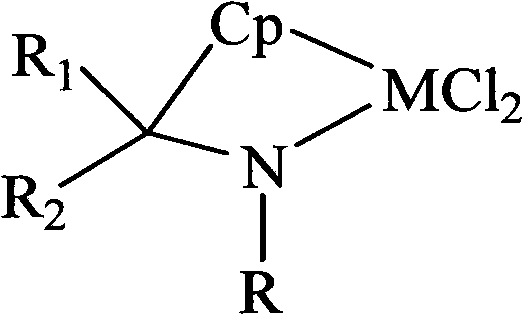

Constrained geometry carbon-bridged single metallocene compound, its preparation and application

A single metallocene, carbon bridge technology, applied in the direction of metallocene, chemical instruments and methods, organic chemistry, etc., can solve the problems of low catalytic activity and catalytic efficiency, achieve high product yield, easy separation and purification, and synthetic route reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] [t-BuNC(Me) 2 (η 5 -C 5 h 4 )] (TiCl 2 )Synthesis

[0041] Dissolve 20mmol (1.46g) of tert-butylamine in 55mL of THF, stir at 0°C, add 12mL of 1.67M n-BuLi n-hexane solution, react for 30 hours to obtain a white turbid suspension, remove the solvent under reduced pressure, and the remaining solid Wash with 15 mL of n-hexane to obtain white powder A; dissolve the above white powder A with 15 mL of THF, add 20 mmol (2.14 g) of 6,6-dimethylfulvene, the white suspension immediately becomes clear, and remove under reduced pressure after 50 hours of reaction Solvent, wash the remaining solid with 15mL of n-hexane to obtain white powder B; add 30mL of THF to dissolve the white powder B, then add 12mL of 1.67M n-BuLi n-hexane solution, react for 30 hours, remove the solvent under reduced pressure, and use 15mL of the remaining solid Wash with n-hexane to obtain white powder dilithium salt C; add 30mL THF to dissolve the white powder C, stir at -30°C, and slowly add 20mmol ...

Embodiment 2

[0043] [t-BuNC(Me) 2 (η 5 -C 5 h 4 )] (ZrCl 2 )Synthesis

[0044] Dissolve 20mmol (1.46g) of tert-butylamine in 30mL of THF, stir at 0°C, add 12mL of 1.67M n-BuLi n-hexane solution, react for 40 hours to obtain a white turbid suspension, remove the solvent under reduced pressure, and the remaining solid Wash with 10 mL of n-hexane to obtain white powder A; dissolve the above white powder A with 15 mL of THF, add 20 mmol (2.14 g) of 6,6-dimethylfulvene, the solution becomes clear immediately, and remove the solvent under reduced pressure after reacting for 50 hours. Wash the remaining solid with 10 mL of n-hexane to obtain white powder B; add 25 mL of THF to dissolve the white powder B, then add 12 mL of 1.67 M n-BuLi n-hexane solution, react for 40 hours to obtain a white turbid suspension, remove the solvent under reduced pressure, Wash the remaining solid with 15 mL of n-hexane to obtain dilithium salt C as a white powder; add 15 mL of THF to dissolve the white powder C...

Embodiment 3

[0046] [t-BuNC(CH 2 ) 5 (η 5 -C 5 h 4 )] (ZrCl 2 )synthesis

[0047] Dissolve 20mmol (1.46g) of tert-butylamine in 35mL of THF, stir at 0°C, add 12mL of 1.67M n-BuLi n-hexane solution, react for 40 hours to obtain a white turbid suspension, remove the solvent under reduced pressure, and the remaining solid Wash with 10 mL of n-hexane to obtain white powder A; dissolve the above white powder A with 15 mL of THF, add 20 mmol (2.48 g) of 6,6-pentamethylenefulvene, the solution becomes clear, and remove the solvent under reduced pressure after reacting for 48 hours. The remaining solid was washed with 10 mL of n-hexane to obtain a white powder B; 15 mL of THF was added to dissolve the white powder B, and then 12 mL of 1.67 M n-BuLi n-hexane solution was added to react for 24 hours to obtain a white turbid suspension, and the solvent was removed under reduced pressure. The remaining solid was washed with 10 mL of n-hexane to obtain dilithium salt C as a white powder; add 15 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com